Multi-layer S-shaped coiled tube type flash heater

A coil type and heater technology, applied in the direction of heat exchanger shell, lighting and heating equipment, tubular elements, etc., can solve the problems of low volume area of integrated flash evaporator, large equipment volume, low material flow rate, etc., and achieve structural Simple, high volume area, and the effect of preventing heat medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

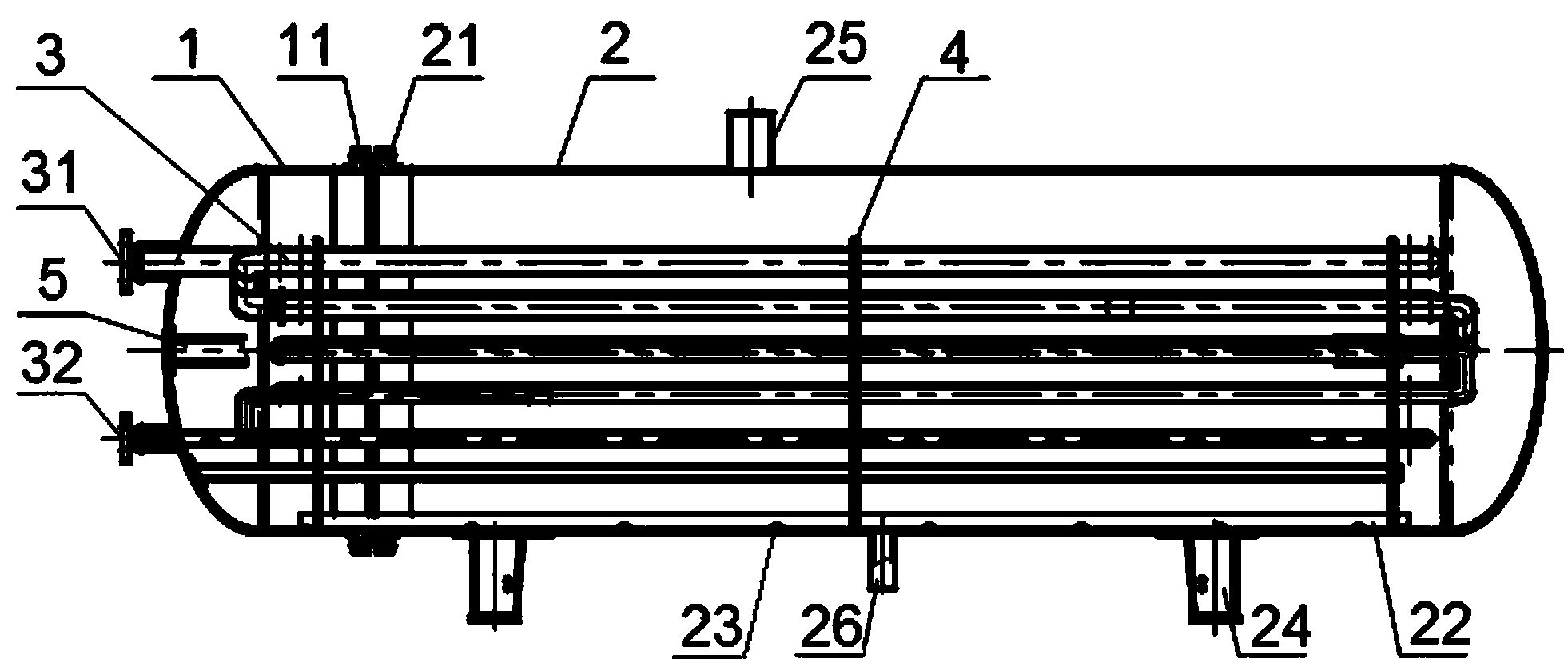

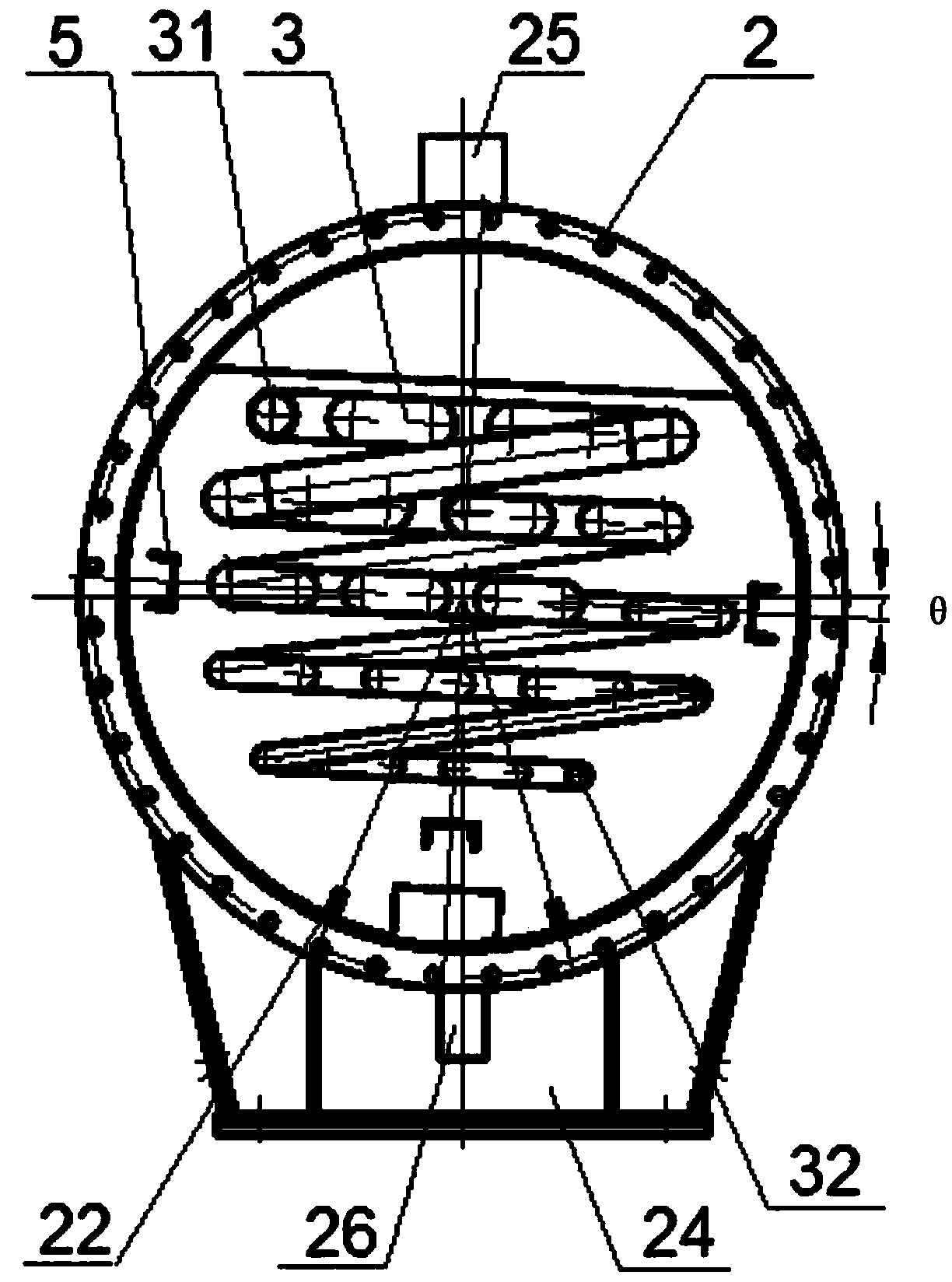

[0024] A multi-layer snake coil flash heater, such as figure 1 with figure 2 As shown, it includes a head 1, a cylinder body 2, a coil assembly 3 and a support plate 4. The head 1 and the cylinder body 2 are detachably connected through a head flange 11 and a cylinder body flange 21. The disk The pipe assembly 3 is located in the head 1 and the cylinder body 2, and is fixedly connected with the head 1. The coil assembly 3 is arranged in 5 layers from bottom to top, and the coils in each layer are arranged reciprocatingly in an S shape. The total length of the coil is about 40000mm, the coil pipe diameter gradually increases from bottom to top, as follows: φ45mm, φ57mm, φ76mm and φ89mm. The coil lengths of the four different pipe diameters are all about 10000mm. Different pipe diameters are connected by different diameter pipes. The bottoms of each layer of coils are on the same plane, and the plane has an included angle of 3 degrees with the horizontal plane, and the plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com