Novel hydrodynamic lubrication demonstrator

A fluid dynamic pressure and demonstrator technology, which is applied in the field of demonstration teaching aids, can solve the problems of not intuitive classroom efficiency, students' difficulty in understanding, etc., and achieve the effects of excellent chemical resistance, obvious phenomena, and lightening the weight of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

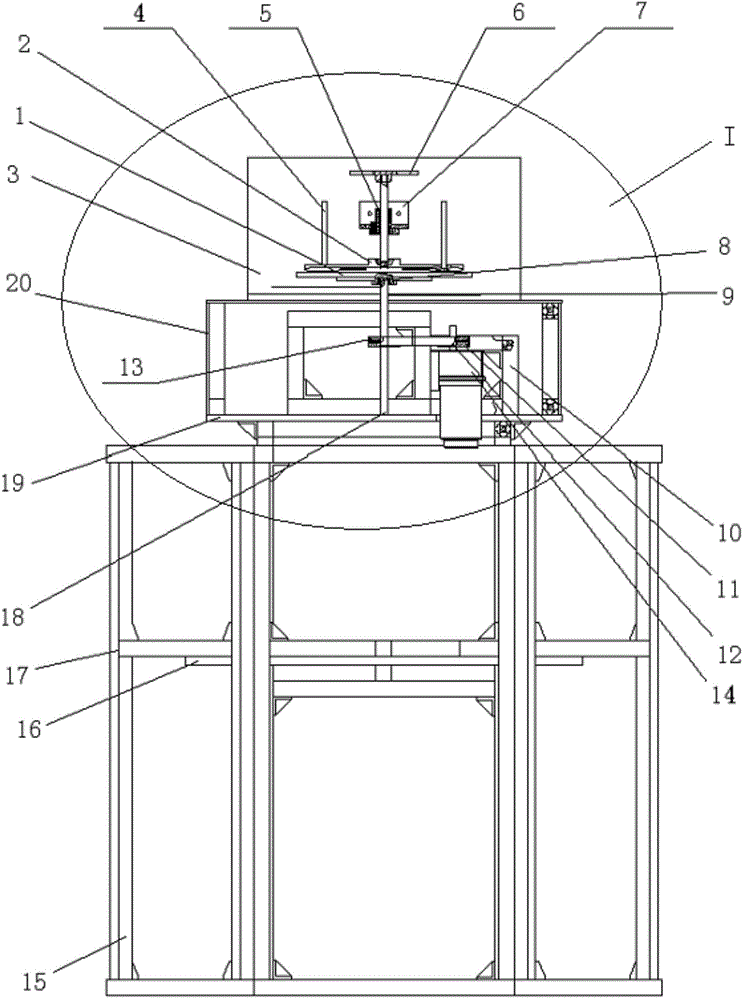

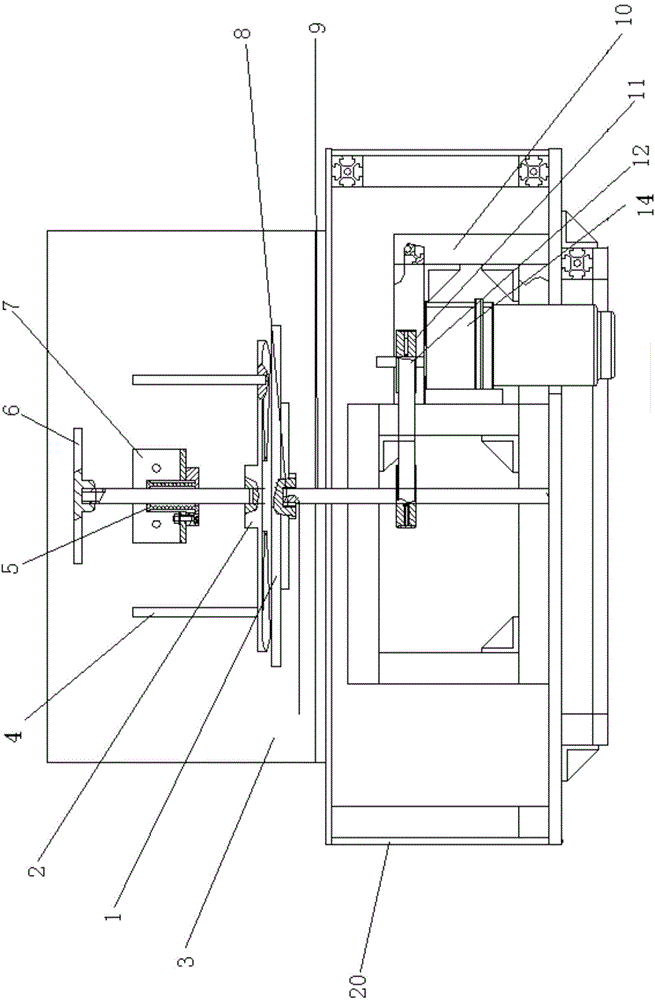

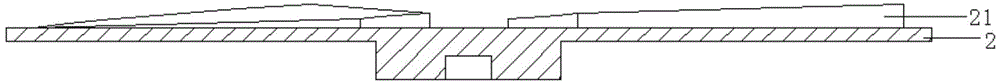

[0042] refer to Figure 1 to Figure 6, a new type of hydrodynamic lubrication demonstration instrument, including a moving ring 1, a static ring 2, an oil tank 3 filled with silicone oil, a motor 14 and a transmission device, the moving ring 1 and the static ring 2 are arranged in the oil tank 3, The static ring 2 is arranged above the moving ring 1, and the moving ring 1 and the static ring 2 are oil-sealed; the center of the moving ring 1 is connected with a main shaft 18 through a flat key 8, and the main shaft 18 is The motor shaft of the motor 14 is connected through the transmission device; when at rest, the static ring is in contact with the moving ring; when rotating, an oil film is formed between the moving ring and the static ring; The lower surface of the static ring is provided with wedge-shaped protrusions 21 at intervals along the circumferential direction, and the lower surface of the static ring 2 cooperates with the upper surface of the moving ring 1 to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com