A kind of steel ring bra and its manufacturing process

A technology without rims and bras, applied in clothing, bras, applications, etc., can solve the problems of complicated sewing process, easy fluff falling off, allergies, etc., and achieve the effect of comfortable wearing and avoiding rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

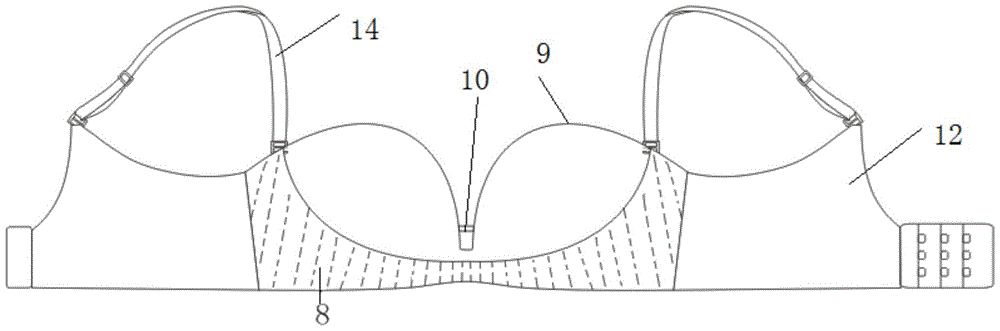

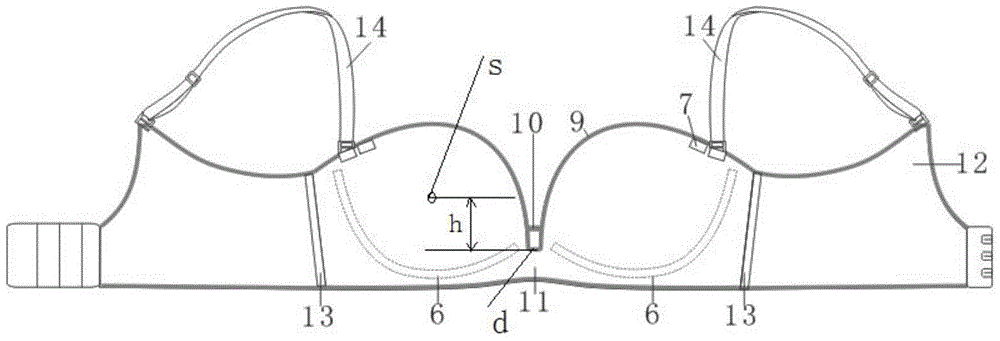

[0027] Such as Figure 1 ~ Figure 4 As shown, the bra without rims of this embodiment includes a main body and shoulder straps 14 , the main body includes a mold cup and an outer layer of material wrapping the inner and outer sides of the mold cup.

[0028] The manufacturing process of the mold cup is as follows:

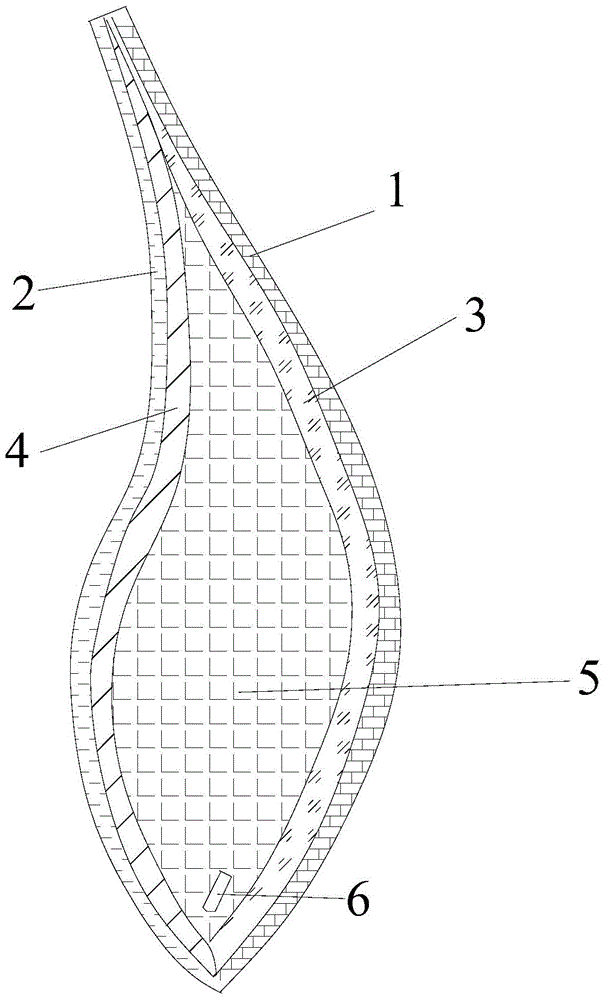

[0029] First, the face cloth 1 and the face cotton 3 are bonded with an adhesive to form the face, and the inner cloth 2 and the inner cotton 4 are bonded with an adhesive to form the inner part, and then the face and the inner part are added with a supporting cotton body 5 and the supporting ring 6 are formed by mold pressing at a high temperature of 190° C., and the whole process is completed in one go. The surface of the cup and the inside of the cup are smooth and comfortable, and the skin-adhering surface is smooth and comfortable after wearing; since the lining 2 is made of nylon, the lining 2 and the lining 4 are first bonded by adhesive , the fitting surfa...

Embodiment 2

[0036] The difference from the first embodiment is that the compression molding temperature used in this embodiment is 200° C., and the rest are the same as the first embodiment, which will not be repeated here.

Embodiment 3

[0038] The difference from the first embodiment is that the compression molding temperature used in this embodiment is 210° C., and the rest are the same as the first embodiment, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com