Method for preparing porous functional carbon fiber cluster from waste cotton textiles

A carbon fiber and textile technology, which is applied in the field of carbon fiber preparation by using waste cotton textiles, can solve the problems of high equipment requirements, difficult effective combination, poor functionality, etc., and achieve the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Soak the waste cotton textiles that have been simply crushed in 10% KH-550 solution at room temperature for 10 minutes, drain the solution, then soak in 10% ammonium chloride solution for 10 minutes, drain the solution, and finally place it at room temperature for 30 minutes. % zinc chloride solution for 16 hours, drain the solution and dry.

[0030] Pre-oxidize the dried waste cotton textiles at 150°C for 20 minutes, then raise the temperature to 250°C for 20 minutes; then pass in nitrogen gas, heat up to 350°C at a speed of 10°C / min, keep warm for carbonization for 40 minutes, and then heat up to 550°C , insulation carbonization 40min.

[0031] First pickle the black product obtained with concentrated hydrochloric acid at 90°C with a volume ratio of 1:10 to remove zinc chloride remaining on the surface of the product, then wash with distilled water at 100°C until the pH value is about 7, dry and sieve , to obtain porous functional carbon fiber clusters.

Embodiment 2

[0033] Soak the waste cotton textiles that have been simply crushed in 10% KH-550 solution at room temperature for 10 minutes, drain the solution, then soak in 10% ammonium chloride solution for 10 minutes, drain the solution, and finally place it at room temperature for 30 minutes. % zinc chloride solution for 16 hours, drain the solution and dry.

[0034] Pre-oxidize the dried waste cotton textiles at 150°C for 30 minutes, then raise the temperature to 250°C for 30 minutes; then pass nitrogen gas, heat up to 400°C at a speed of 10°C / min, keep warm for 90 minutes, and then heat up to 650°C , insulation carbonization 35min.

[0035] First pickle the black product obtained with concentrated hydrochloric acid at 90°C with a volume ratio of 1:10 to remove zinc chloride remaining on the surface of the product, then wash with distilled water at 100°C until the pH value is about 7, dry and sieve , to obtain porous functional carbon fiber clusters.

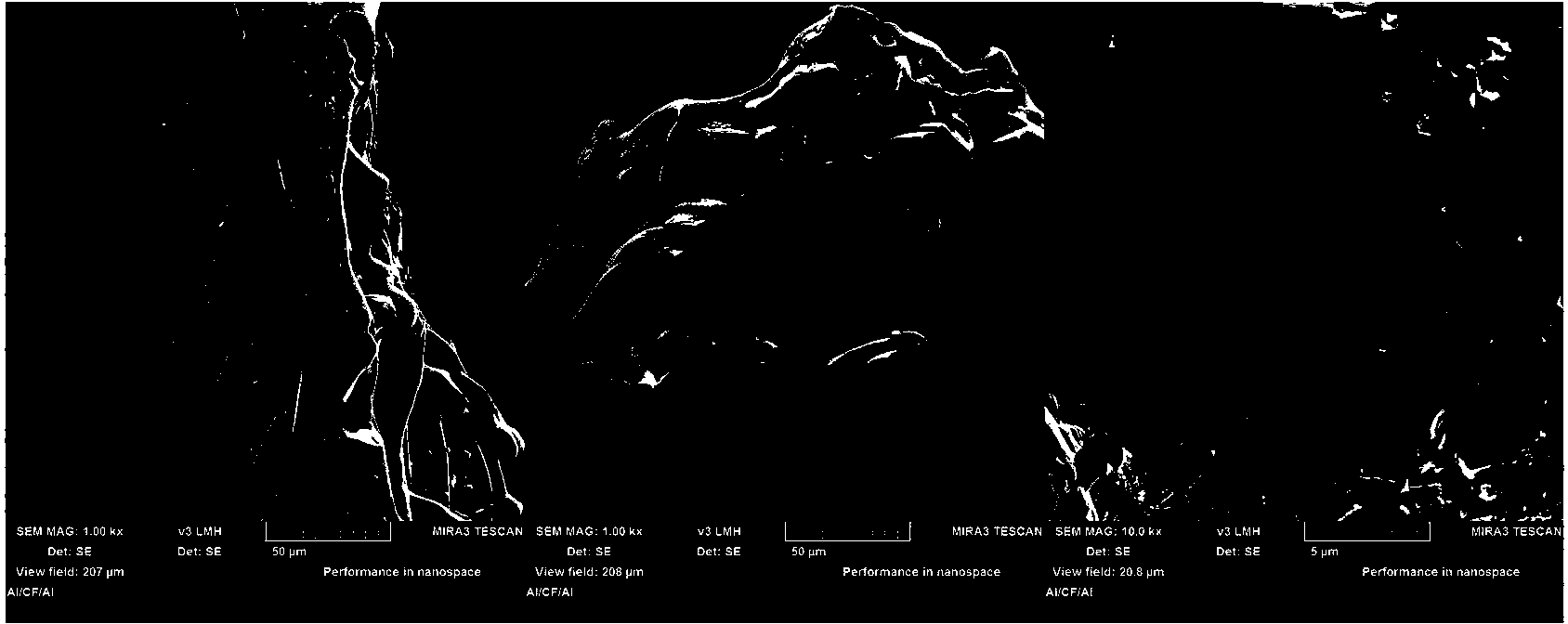

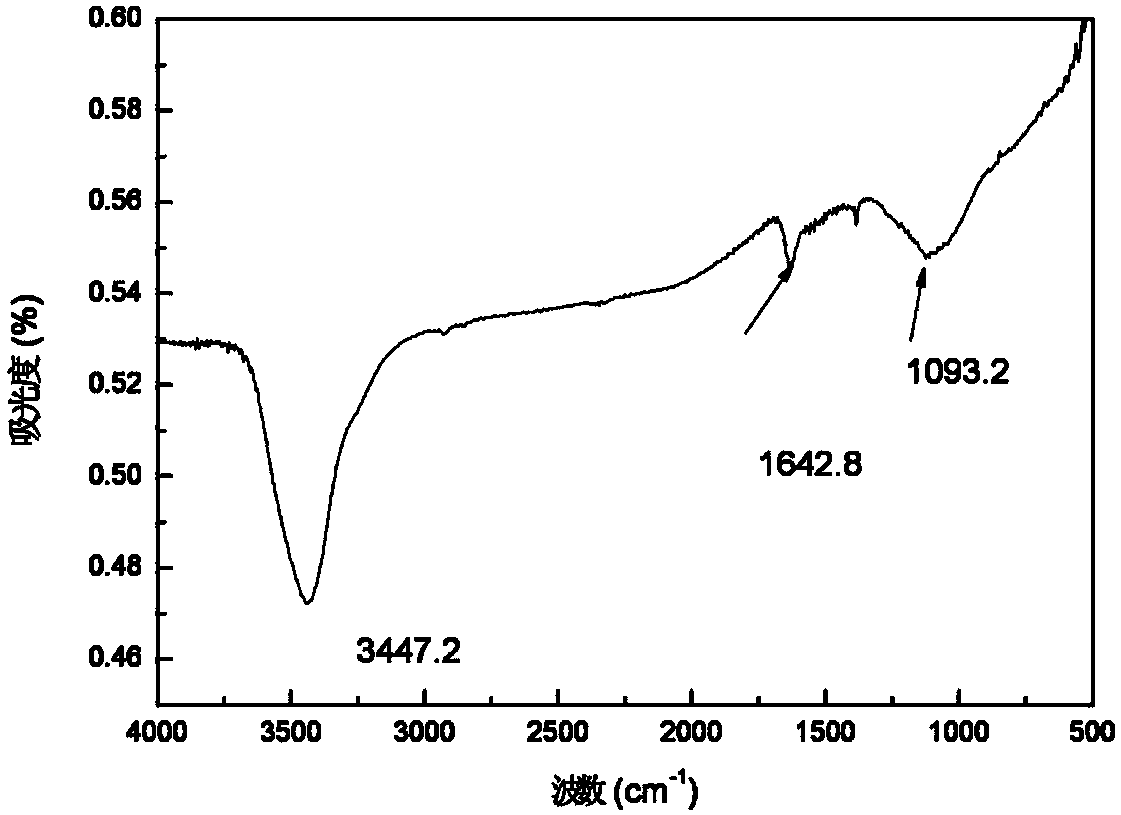

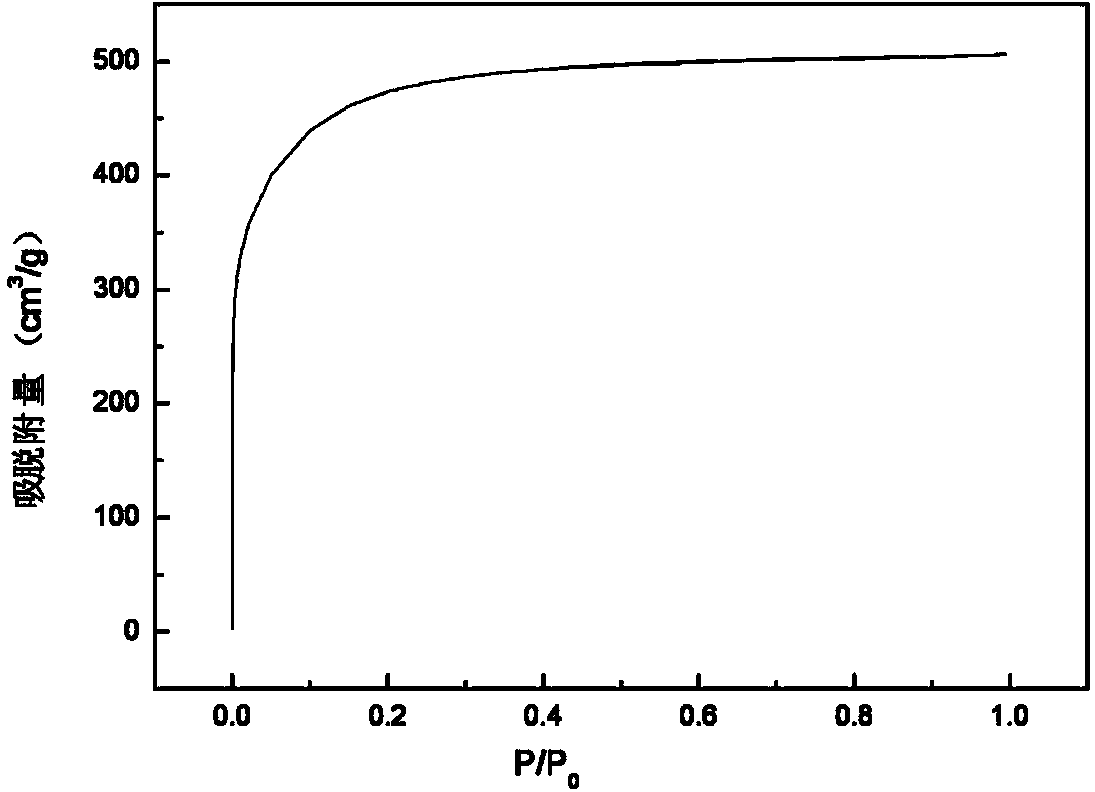

[0036] The surface morphology o...

Embodiment 3

[0040] Soak waste cotton textiles that have been simply crushed in 10% KH-550 solution at room temperature for 10 minutes, drain the solution, then soak in 10% ammonium chloride solution for 10 minutes, drain the solution, and finally place it at room temperature for 50 minutes. % zinc chloride solution for 24 hours, drain the solution and dry.

[0041] Pre-oxidize the dried waste cotton textiles at 200°C for 40 minutes, then raise the temperature to 300°C for 30 minutes; then pass in nitrogen, heat up to 450°C at a rate of 10°C / min, keep warm for 60 minutes, and then heat up to 950°C , insulation carbonization 40min.

[0042] First pickle the black product obtained with concentrated hydrochloric acid at 90°C with a volume ratio of 1:10 to remove zinc chloride remaining on the surface of the product, then wash with distilled water at 100°C until the pH value is about 7, dry and sieve , to obtain porous functional carbon fiber clusters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com