Antifreeze agent for mortar

A technology of antifreeze and mortar, which is applied in the field of building materials, can solve the problems that mortar is susceptible to freezing in winter, and achieve the effects of good construction, good dispersion and low cost of filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

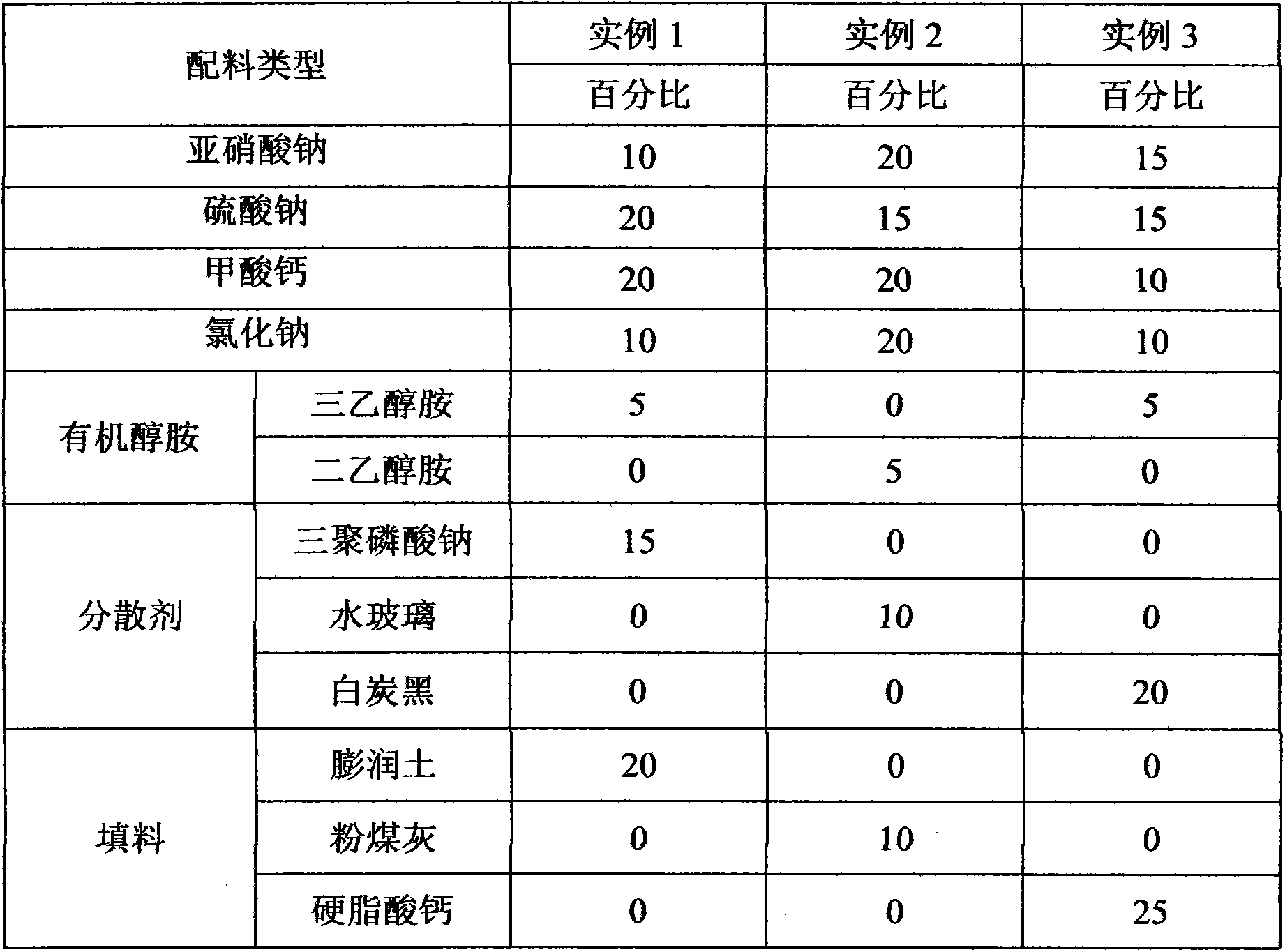

[0016] Products and percentages adopted in each embodiment of the present invention are shown in the following table:

[0017]

[0018] The mixing equipment of the process of the three embodiments of the present invention is a high-speed mixer. After starting up, add filler first, dry mix for 2 minutes, then add 1 / 2 dispersant, stir for 5 minutes, then add sodium sulfate, calcium formate, sodium chloride in turn, stir for 10 minutes, then slowly add organic alcohol amine dropwise within 2 minutes, Finally, add sieved 60-mesh sodium nitrite and 1 / 2 dispersant and mix for 20 minutes before discharging.

[0019] This product has been used in a mortar factory in Beijing. After trial construction, it was constructed in winter at a temperature of 0~-10°C. It has stable performance during use and has good antifreeze performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com