Device capable of eliminating internal stress and microcracks of extruded graphite pipe

A technology of micro-cracks and internal stress, applied in the field of chemical materials, can solve the problems of short service life and micro-leakage during use of graphite tube heat exchangers, and achieve the elimination of internal stress and micro-cracks, impact resistance and anti-leakage Effects of performance improvement and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

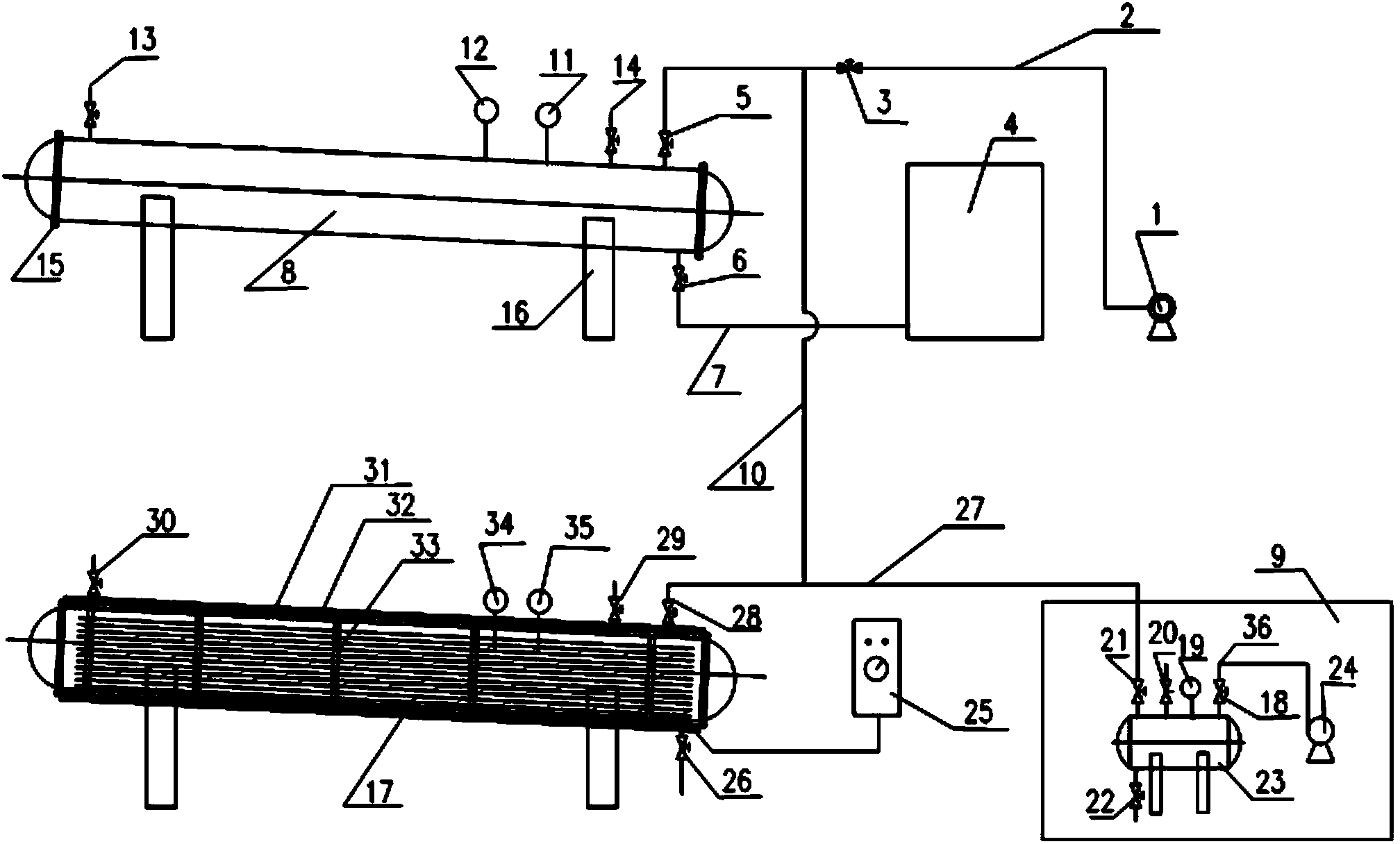

[0021] The vacuum pump 1 is connected to the horizontal impregnation kettle 8 through the first pipeline 2, the first valve 3 and the second valve 5, the resin tank 4 is connected to the horizontal impregnation kettle 8 through the second pipeline 7 and the third valve 6, and the pressurization device 9 is connected to the horizontal impregnation tank 8 through the fourth valve 21, the fourth pipeline 27, the third pipeline 10 and the second valve 5, and the pressurizing device 9 is connected to the Horizontal heat treatment kettle 17 is connected, and heater 32 is arranged on horizontal heat treatment kettle 17.

[0022] Both ends of the horizontal impregnation kettle 8 are equipped with heads 15, which are placed on the saddle 16. The length of the horizontal impregnation kettle 8 is 5000mm, the diameter is Ф600, the thickness of the cylinder is 8mm, the first safety valve 14, the first pressure gauge 12. The first emptying valve 13 and the thermometer 11 are connected to th...

Embodiment 2

[0032] The vacuum pump 1 is connected to the horizontal impregnation kettle 8 through the first pipeline 2, the first valve 3 and the second valve 5, the resin tank 4 is connected to the horizontal impregnation kettle 8 through the second pipeline 7 and the third valve 6, and the pressurization device 9 is connected to the horizontal impregnation tank 8 through the fourth valve 21, the fourth pipeline 27, the third pipeline 10 and the second valve 5, and the pressurizing device 9 is connected to the Horizontal heat treatment kettle 17 is connected, and heater 32 is arranged on horizontal heat treatment kettle 17.

[0033] Both ends of the horizontal impregnation kettle 8 are equipped with heads 15, which are placed on the saddle 16. The length of the horizontal impregnation kettle 8 is 6000mm, the diameter is Ф800, and the thickness of the cylinder is 10mm. The first safety valve 14 and the first pressure gauge 12. The first emptying valve 13 and the thermometer 11 are connect...

Embodiment 3

[0043] The vacuum pump 1 is connected to the horizontal impregnation kettle 8 through the first pipeline 2, the first valve 3 and the second valve 5, the resin tank 4 is connected to the horizontal impregnation kettle 8 through the second pipeline 7 and the third valve 6, and the pressurization device 9 is connected to the horizontal impregnation tank 8 through the fourth valve 21, the fourth pipeline 27, the third pipeline 10 and the second valve 5, and the pressurizing device 9 is connected to the The horizontal heat treatment kettle 17 is connected, and a heater 32 is arranged on the horizontal heat treatment kettle.

[0044]Both ends of the horizontal impregnation kettle 8 are equipped with heads 15, which are placed on the saddle 16. The length of the horizontal impregnation kettle 8 is 7000 mm, the diameter is Ф1000, and the thickness of the cylinder is 14 mm. The first safety valve 14 and the first pressure gauge 12. The first emptying valve 13 and the thermometer 11 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com