A kind of graphene nanosheet material dispersed in natural polysaccharide and preparation method thereof

A technology of graphene nanosheets and natural polysaccharides, applied in the field of nanomaterials, can solve the problems of complex preparation process, incomplete structure of reduction method, low cost, etc., and achieve the effect of low cost and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for preparing the graphene nanosheet material dispersed in natural polysaccharides, the method may further comprise the steps:

[0027] Microcrystalline cellulose derived from natural herbal cellulose is mixed with solid graphite at a weight ratio of 99:1, the mixture is added to a grinder, and mechanical grinding is carried out without adding any grinding agent. The grinding speed is 300r.p.m, and the time is 16h. The thickness of the natural herbal cellulose is 0.35-7nm single-layer graphene nano sheet material.

Embodiment 2

[0029] Same as Example 1, the difference is that the natural herbal cellulose is replaced by natural woody cellulose; the natural woody cellulose is mixed with solid graphite at 20:1 by weight; the grinding speed is 500r.p.m, and the time is 2h; A single-layer graphene nanosheet material with a thickness of 0.35-7nm dispersed in natural woody cellulose was obtained.

Embodiment 3

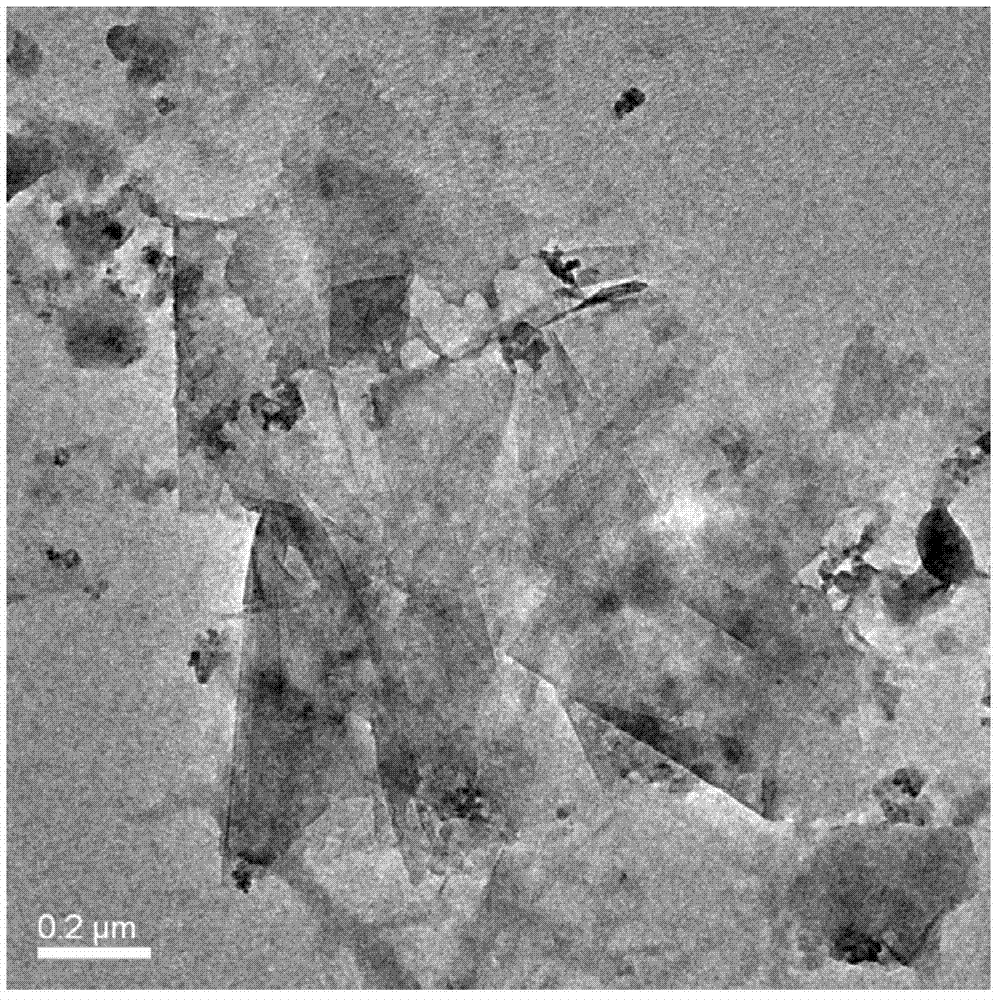

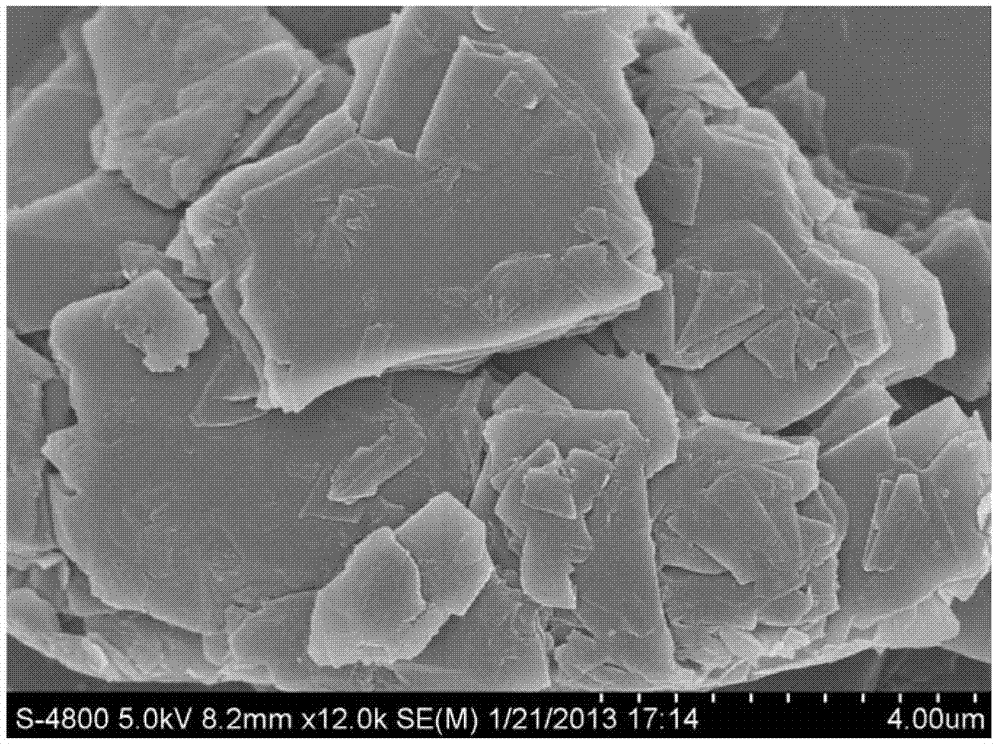

[0031] A preparation method for preparing the graphene nanosheet material dispersed in natural polysaccharides, the method comprises the following steps: mixing natural herb cellulose and solid graphite by 1:1 weight, adding the mixture to a grinder, and then adding The solvent DMF with 50 times the quality of natural polysaccharides is mechanically ground, the grinding speed is 300r.p.m, and the time is 24h; the single-layer or multi-layer graphene nanosheets with a thickness in the range of 0.35nm to 7nm dispersed in natural herbal cellulose are obtained. materials (such as figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com