A multi-element modified lithium-rich manganese-based positive electrode material and preparation method thereof

A cathode material, lithium-rich manganese-based technology, which is applied in the field of multi-element modified lithium-rich manganese-based cathode materials and their preparation, can solve the problem that the stability of the morphology and structure of the material cannot be guaranteed, the specific energy of the battery cannot be provided, and halogen elements cannot be provided. Low reactivity and other problems, to achieve the effect of novel preparation method, friendly surrounding environment, and stable material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

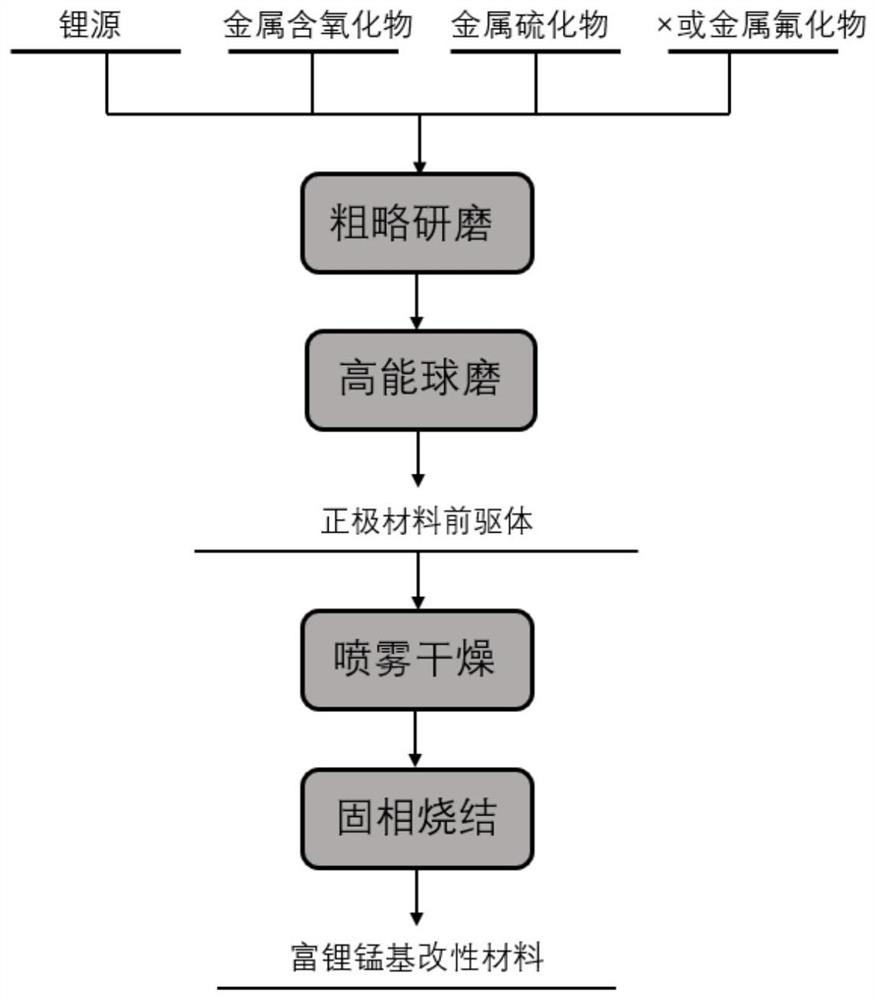

[0034] The preparation method of the lithium-rich manganese-based positive electrode material modified by replacing part of the lattice oxygen with sulfur element in this experiment is carried out according to the following steps:

[0035] Step 1: Put Li 2 CO 3 (5% excess), TiS 2 , MnO, MnO 2 Weigh according to the proportion required by the stoichiometric formula of the material, the total mass is about 2g, roughly grind and mix.

[0036] Step 2: In an atmosphere of high-purity argon, put the mixture into the 2 In the ball milling tank of the grinding balls, pour absolute ethanol as a coolant and seal it tightly. Afterwards, the sealed jar was put into a planetary ball mill and ground for 48 hours at a speed of 500rps / min.

[0037]Step 3: Then take out the suspension sample, and carry out spray drying to remove the liquid while completing the spherical granulation of the precursor secondary particles.

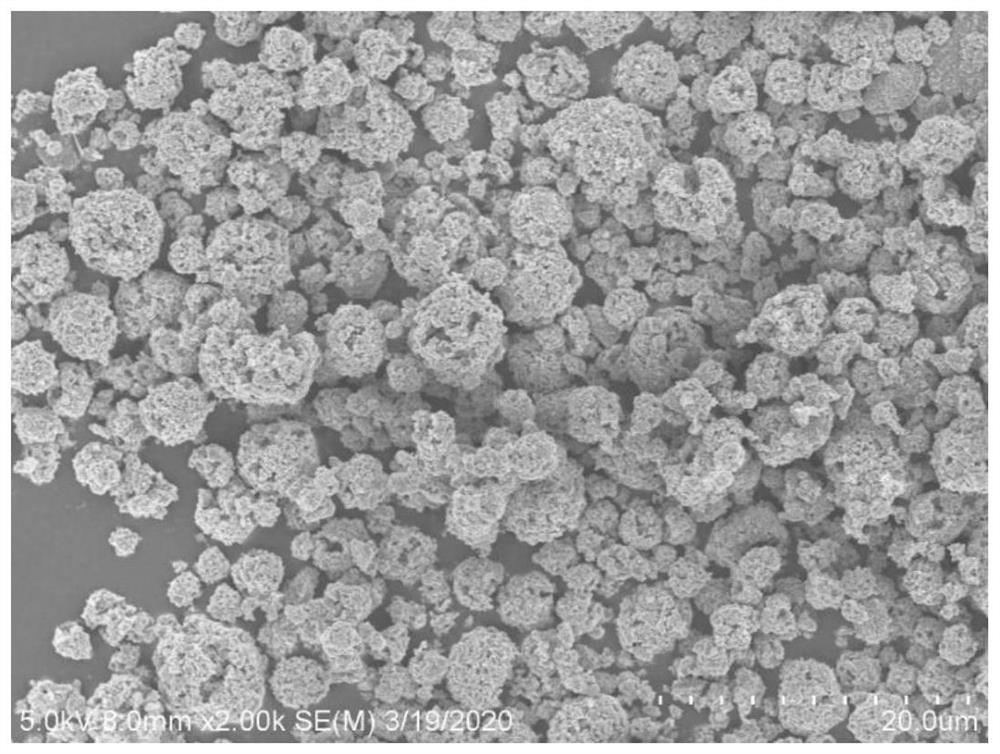

[0038] Step 4: Put the sample in a tube furnace, bake it at 850°C f...

Embodiment 2

[0041] Step 1: LiOH·H 2 O (excess 5%), TiS 2 , MnCO 3 , CeO 2 Weigh according to the ratio required by the stoichiometric formula of the material, wherein the stoichiometric number of sulfur is 0.1, the total mass is approximately 2g, and roughly ground and mixed.

[0042] Step 2: In an atmosphere of high-purity argon, put the mixture into the 2 In the ball mill jar of the grinding balls, pour alcohol as a coolant and seal it tightly. Afterwards, the sealed jar was put into a planetary ball mill, and ball milled for 72 hours at a speed of 400rps / min.

[0043] Step 3: Then take out the suspension sample, and carry out spray drying to remove the liquid while completing the spherical granulation of the precursor secondary particles.

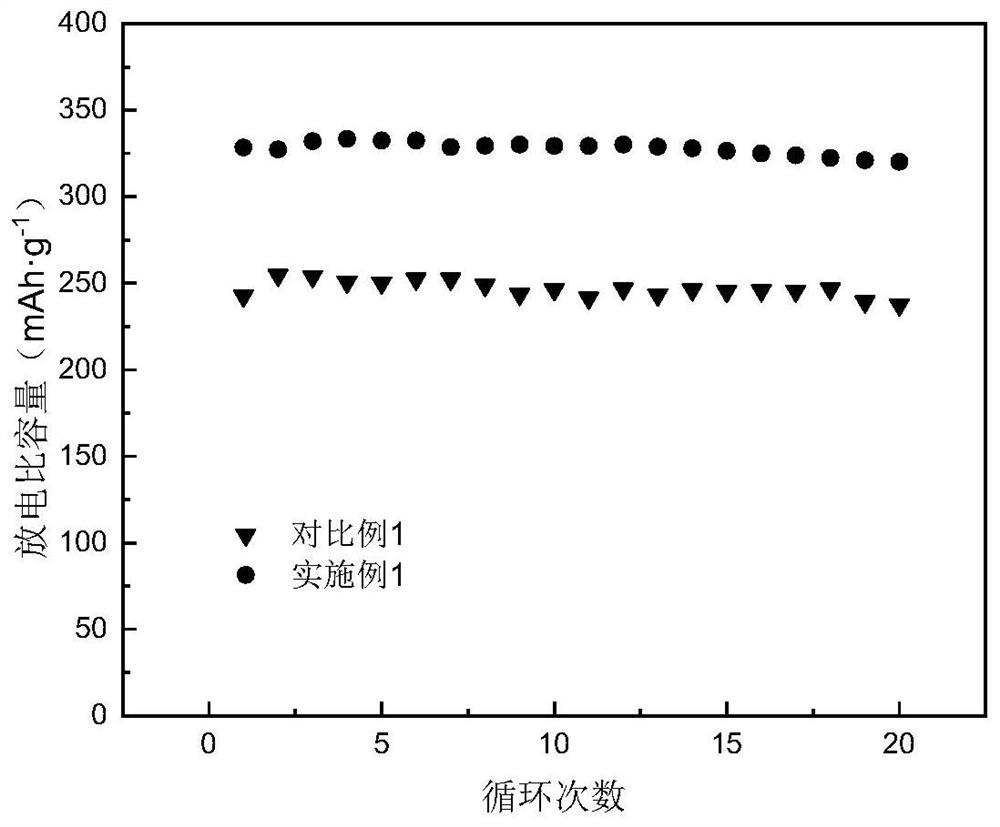

[0044] Step 4: Put the sample in a tube furnace, bake it at 900°C for 5 hours in an inert gas atmosphere, and cool it down to room temperature naturally to obtain the target product. The modified lithium-rich manganese-based cathode material ha...

Embodiment 3

[0047] The preparation method of the lithium-rich manganese-based positive electrode material modified by partially replacing the lattice oxygen with sulfur in this experiment is carried out according to the following steps:

[0048] Step 1: Put Li 2 CO 3 (5% excess), TiS 2 , MnO, NiF, and LiF are weighed according to the proportion required by the stoichiometric formula of the material, the total mass is roughly 2g, and roughly ground and mixed.

[0049] Step 2: In an atmosphere of high-purity argon, put the mixture into the 2 In the ball milling tank of the grinding balls, pour absolute ethanol as a coolant and seal it tightly. Afterwards, the sealed jar was put into a planetary ball mill, and ball milled for 24 hours at a speed of 600rps / min.

[0050] Step 3: Then take out the suspension sample, and carry out spray drying to remove the liquid while completing the spherical granulation of the precursor secondary particles.

[0051] Step 4: Put the sample in a tube furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com