Fume denitration composite catalyst and preparation method thereof

A composite catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of easy pulverization of the catalyst, poor wear resistance, etc., and achieve good thermal stability and strong water vapor resistance , The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

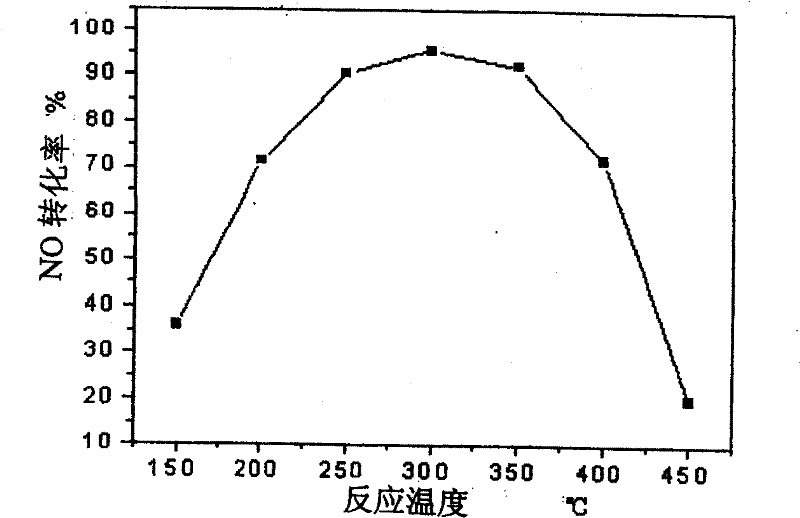

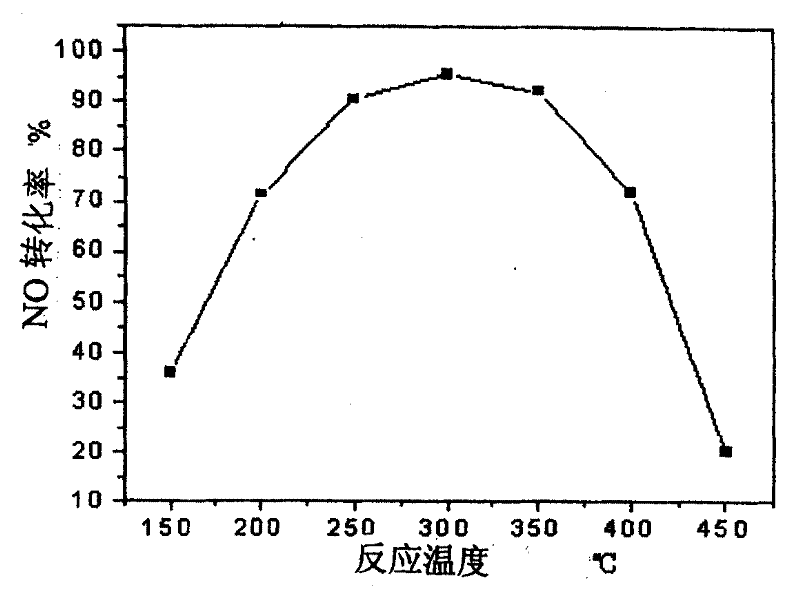

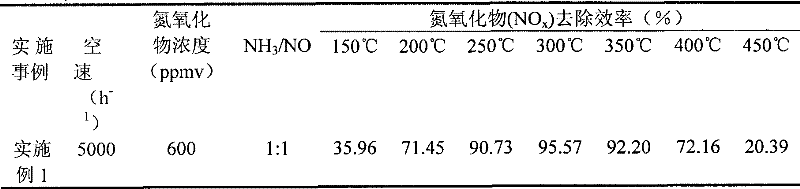

Embodiment 1

[0024] (1) Al 2 O 3 -SiO 2 Preparation of composite sol

[0025] First dissolve 20g of pseudo-boehmite powder in 285ml of deionized water, add about 10g of concentrated nitric acid with a concentration of 68% dropwise while stirring, and then heat to 80°C, so that the pH value of the prepared sol is 0.5 and the relative density is 1.15. According to tetraethyl orthosilicate (TEOS): ethanol: H 2 O:H + =1: 6.4: 3.8: 0.085 molar ratio, fully mix ethyl orthosilicate and absolute ethanol, add dropwise a mixture of deionized water and glacial acetic acid (acidic catalyst) under strong stirring with a magnetic stirrer, add dropwise After the reaction mixture was stirred and refluxed at a constant temperature of 70 °C for 50 min, stable SiO was obtained. 2 sol. Finally, according to the molar ratio of element Al:Si of 3:1, the aluminum glue and silica gel were mixed and stirred at a constant temperature of 70 °C for 2 hours to obtain stable Al 2 O 3 -SiO 2composite sol;

[0...

Embodiment 2

[0034] (1) Al 2 O 3 -SiO 2 Preparation of composite sol

[0035] First dissolve 20g of pseudo-boehmite powder in 285ml of deionized water, add about 9g of concentrated nitric acid with a concentration of 68% dropwise while stirring, and then heat to 70°C, so that the pH value of the prepared sol is 1.1 and the relative density is 1.16. According to tetraethyl orthosilicate (TEOS): ethanol: H 2 O:H + =1: 5: 4: 0.08 molar ratio, fully mix ethyl orthosilicate and absolute ethanol, add dropwise a mixture of deionized water and nitric acid (acidic catalyst) under strong stirring with a magnetic stirrer, and complete the dropwise addition After the reaction mixture was stirred and refluxed at a constant temperature of 70 °C for 40 min, stable SiO was obtained. 2 sol. Finally, according to the molar ratio of element Al:Si of 1:1, the aluminum glue and silica gel were mixed, and stirred at a constant temperature of 70 ° C for 2.5 hours, that is, stable Al was obtained. 2 O 3 -...

Embodiment 3

[0043] (1) Al 2 O 3 -SiO 2 Preparation of composite sol

[0044] First dissolve 20g of pseudo-boehmite powder in 285ml of deionized water, add about 8.9g of concentrated nitric acid with a concentration of 68% dropwise while stirring, and then heat to 80°C so that the pH value of the prepared sol is 1.5 and the relative density is 1.17. According to tetraethyl orthosilicate (TEOS): ethanol: H 2 O:H + =1:7:4:0.085 molar ratio, fully mix ethyl orthosilicate and absolute ethanol, add the mixture of deionized water and sulfuric acid (acidic catalyst) dropwise under strong stirring with a magnetic stirrer, and the dropwise addition is completed. After the reaction mixture was stirred and refluxed at a constant temperature of 65 °C for 75 min, stable SiO was obtained. 2 sol. Finally, according to the molar ratio of element Al:Si of 5:1, the aluminum glue and silica gel were mixed and stirred at a constant temperature of 80 °C for 4 hours to obtain stable Al 2 O 3 -SiO 2 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com