Photocatalytic sterilization self-cleaning inkjet micropowder brick and preparation method thereof

A technology of photocatalysis and micro-powder bricks, which is applied in the field of building materials, can solve the problems of unsustainable disinfection and sterilization methods, poor indoor air quality, and loss of bactericidal effect, etc., and achieve the effect of rich patterns and colors, inhibition of crystal transformation, and strong decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The composition of raw materials is as follows:

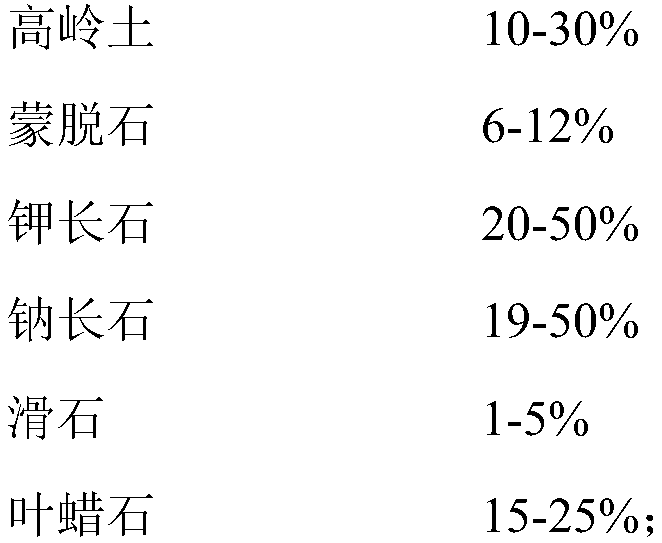

[0040] The composition of blank weight percentage is as follows:

[0041]

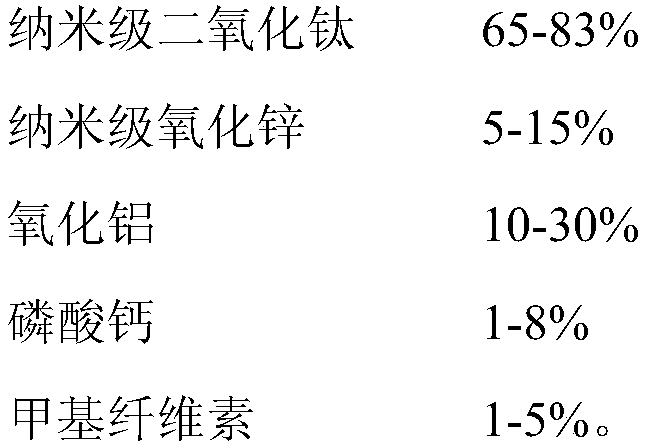

[0042] Nano glaze weight percent composition is as follows:

[0043]

[0044] The weight ratio of blank and nano glaze is 200:1.

[0045] The preparation method is as follows:

[0046] (1) The billet raw material is ground into mud by mixing ball, and after the mud is iron-removed and sieved, the multi-tube free distribution system is used to distribute the material in a conical three-dimensional manner;

[0047] (2) Nano-glaze raw materials are mixed and ball-milled to obtain glaze slurry, the specific gravity of the glaze slurry is 1.8g / ml, and the glaze slurry is finely ground and stirred for subsequent use;

[0048] (3) After the blank cloth is finished, divide the blank with a manipulator to form a mesh, spray the glaze slurry into the mesh gap, press and form it, and obtain the brick; the press molding pressure is 260bar, and the n...

Embodiment 2

[0053] The composition of raw materials is as follows:

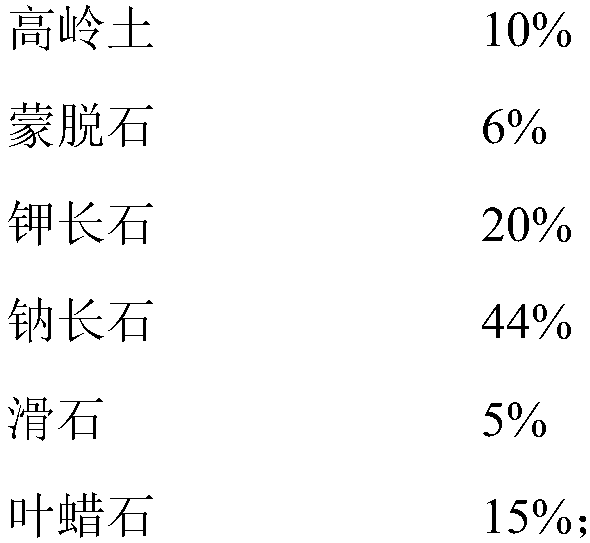

[0054] The composition of blank weight percentage is as follows:

[0055]

[0056] Nano glaze weight percent composition is as follows:

[0057]

[0058] The weight ratio of blank and nano glaze is 200:0.5.

[0059] The preparation method is as follows:

[0060] (1) The raw material of the blank is ground into mud by mixing balls, and the mud is directly colored after iron removal and sieving to form a colored powder, which is distributed in a cone-shaped three-dimensional manner by a multi-tube free distribution system;

[0061] (2) Nano-glaze raw materials are mixed and ball-milled to obtain glaze slurry, the specific gravity of the glaze slurry is 2.5g / ml, the glaze slurry is ground and stirred, and the pigment is appropriately added for subsequent use;

[0062] (3) After the blank cloth is finished, divide the blank with a manipulator to form a mesh, spray the glaze slurry in the mesh gap, press and form it,...

Embodiment 3

[0067] The composition of raw materials is as follows:

[0068] The composition of blank weight percentage is as follows:

[0069]

[0070] Nano glaze weight percent composition is as follows:

[0071]

[0072] The weight ratio of blank and nano glaze is 200:1.5.

[0073] The preparation method is as follows:

[0074] (1) The billet raw material is ground into mud by mixing ball, and after the mud is iron-removed and sieved, the multi-tube free distribution system is used to distribute the material in a conical three-dimensional manner;

[0075](2) Nano-glaze raw materials are mixed and ball-milled to obtain glaze slurry, the specific gravity of the glaze slurry is 2.0g / ml, and the glaze slurry is finely ground and stirred for subsequent use;

[0076] (3) After the blank cloth is finished, divide the blank with a manipulator to form a mesh, spray the glaze slurry into the mesh gap, press and form it, and obtain the brick; the press molding pressure is 270bar, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com