Polyurethane aqueous resin containing Schiff base structure, and preparation method thereof

A water-based resin and Schiff base technology, applied in polyurea/polyurethane coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve problems such as harmful to human health, endangering human health, and paint drop. To achieve the effect of long-lasting antibacterial performance, excellent performance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

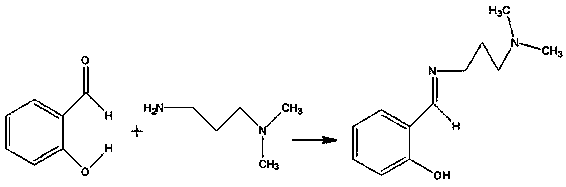

[0031] A kind of salicylaldehyde Schiff base, its preparation process is as follows:

[0032] Add 25.0 parts of salicylaldehyde and 11.0 parts of ethanol to a three-necked reaction kettle equipped with a thermometer, agitator, and condenser tube, raise the temperature to 80°C and stir evenly, and weigh N,N-dimethyl-1,3-propane Dissolve 20.9 parts of diamine in 22.0 parts of ethanol, slowly add it dropwise into the above reaction kettle, and add an appropriate amount of 0.8 parts of glacial acetic acid, stir and reflux for 4-5 hours, wait until the reaction is complete, then cool to room temperature, and let it stand overnight. The crude product was obtained by suction filtration; the obtained crude product was recrystallized with 20.3 parts of ethanol, and dried in vacuum to obtain the salicylaldehyde Schiff base.

Embodiment 2

[0034] A kind of salicylaldehyde Schiff base, its preparation process is as follows:

[0035] Add 22.0 parts of salicylaldehyde and 10.0 parts of ethanol to a three-necked reaction kettle equipped with a thermometer, agitator, and condenser tube, raise the temperature to 80°C and stir evenly, and weigh N,N-dimethyl-1,3-propane Dissolve 18.4 parts of diamine in 20.0 parts of ethanol, then slowly drop it into the above reaction kettle, and add an appropriate amount of 0.6 parts of glacial acetic acid, stir and reflux for 4 to 5 hours, and cool to room temperature after the reaction is complete, and let it stand overnight. The crude product was obtained by suction filtration; the obtained crude product was recrystallized with 29.0 parts of ethanol, and dried in vacuum to obtain the salicylaldehyde Schiff base.

Embodiment 3

[0037] A kind of salicylaldehyde Schiff base, its preparation process is as follows:

[0038]Add 26.0 parts of salicylaldehyde and 11.5 parts of ethanol to a three-necked reaction kettle equipped with a thermometer, agitator, and a condenser, raise the temperature to 80°C and stir evenly, and weigh N,N-dimethyl-1,3-propane Dissolve 21.8 parts of diamine in 24.0 parts of ethanol, then slowly drop it into the above reaction kettle, and add an appropriate amount of 0.7 parts of glacial acetic acid, stir and reflux for 4-5 hours, wait until the reaction is complete, then cool to room temperature, and let it stand overnight. The crude product was obtained by suction filtration; the obtained crude product was recrystallized with 16.0 parts of ethanol, and dried in vacuum to obtain the salicylaldehyde Schiff base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com