Special reinforced regenerated flame-retardant HIPS (high impact polystyrene) for home appliances and preparation technique thereof

A technology of household appliances and flame retardants, which is applied in the field of enhanced recycled flame-retardant HIPS for household appliances and its preparation process, which can solve the problems of unrecoverable cost and achieve the effects of solving brittleness, improving compatibility, and enhancing flame-retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

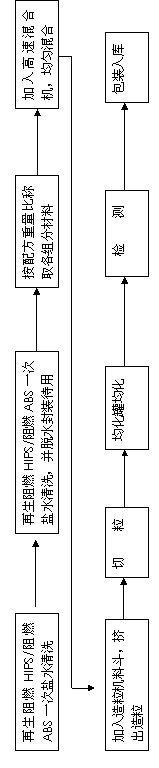

Method used

Image

Examples

Embodiment 1

[0038] Enhanced flame retardant (UL94 / V-0) HIPS material is manufactured according to the following material ratio in parts by weight:

[0039] Regenerated flame retardant HIPS: 76 parts

[0040] Compatibilizer SBR: 6 parts

[0041] Flame retardant: 6 parts

[0042] Recycled flame retardant ABS: 10 parts

[0043] Lubricant: 0.7 parts

[0044] Antioxidant: 0.7 parts

[0045] Anti-dripping agent: 0.6 parts

[0046] The preparation process of enhanced flame retardant (UL94 / V-0) HIPS includes steps:

[0047] A. First pass the broken flame-retardant HIPS or flame-retardant ABS through the salt water with adjusted density, float the flame-retardant HIPS and flame-retardant ABS above the salt water, wash away some impurities, and then pass the flame-retardant HIPS and flame-retardant ABS through Adjust the density of the brine so that it sinks below the brine to clear impurities again.

[0048] B. Dehydrate the flame-retardant HIPS or ABS cleaned in step A, and pack them into ...

Embodiment 2

[0053] The enhanced flame retardant (UL94 / V-0) HIPS material consists of the following parts by weight:

[0054] Flame retardant HIPS: 66 parts

[0055]Compatibilizer SBR: 6 parts

[0056] Flame retardant: 6 parts

[0057] Flame retardant ABS: 20 parts

[0058] Lubricant: 0.7 parts

[0059] Antioxidant: 0.7 parts

[0060] Anti-dripping agent: 0.6 parts

[0061] The preparation method is the same as in Example 1, and will not be repeated here.

Embodiment 3

[0063] The enhanced flame retardant (UL94 / V-0) HIPS material consists of the following parts by weight:

[0064] Flame retardant HIPS: 56 parts

[0065] Compatibilizer SBR: 6 parts

[0066] Flame retardant: 6 parts

[0067] Flame retardant ABS: 30 parts

[0068] Lubricant: 0.7 parts

[0069] Antioxidant: 0.7 parts

[0070] Anti-dripping agent: 0.6 parts

[0071] The preparation method is the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com