A kind of aluminum alloy refining device and refining method thereof

A refining device and technology for aluminum alloys, which are applied to devices for refining and purifying aluminum alloy melts, refining and purifying devices for aluminum alloy melts, and refining fields, can solve the problems of deteriorating working environment, high labor intensity, low thermal efficiency of furnaces, etc. The effect of improving the working environment, reducing labor intensity, and high refining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

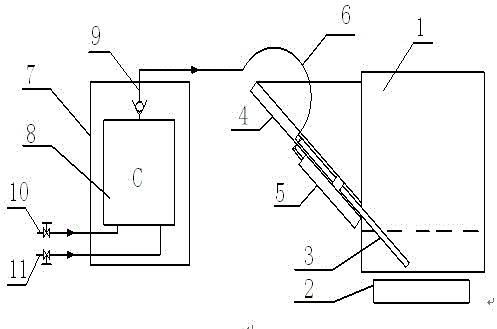

[0030] The invention discloses an aluminum alloy refining device, which comprises a holding furnace 1 for refining and an electromagnetic stirrer 2 installed outside the bottom of the furnace. The side wall of the holding furnace 1 is provided with a number of refining holes, through which a number of The refining tube 3 that can be inserted obliquely, the gas outlet end of the refining tube 3 is installed on the guide bracket 4 on the side wall of the holding furnace 1, the inlet end of the refining tube 3 is connected to the driving cylinder 5, and the refining tube 3 passes through the hose 6 It is connected to the gas adjustment control cabinet 7 , the adjustment control unit 8 in the gas adjustment control cabinet 7 adjusts the gas input through the inlet pipes 10 and 11 , and the gas outlet pipe 9 is connected to the hose 6 .

[0031] In the prior art, the flux jet refining equipment and its method, furnace bottom ventilation brick refining and furnace top gas blowing ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com