High-efficiency intelligent high-side electronic load switch with wide voltage adaptability

An electronic load and adaptable technology, applied in the direction of electronic switches, electrical components, pulse technology, etc., can solve problems such as failure to work normally, performance degradation, difficulties, etc., and achieve functions and scope expansion, high safety, and low loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

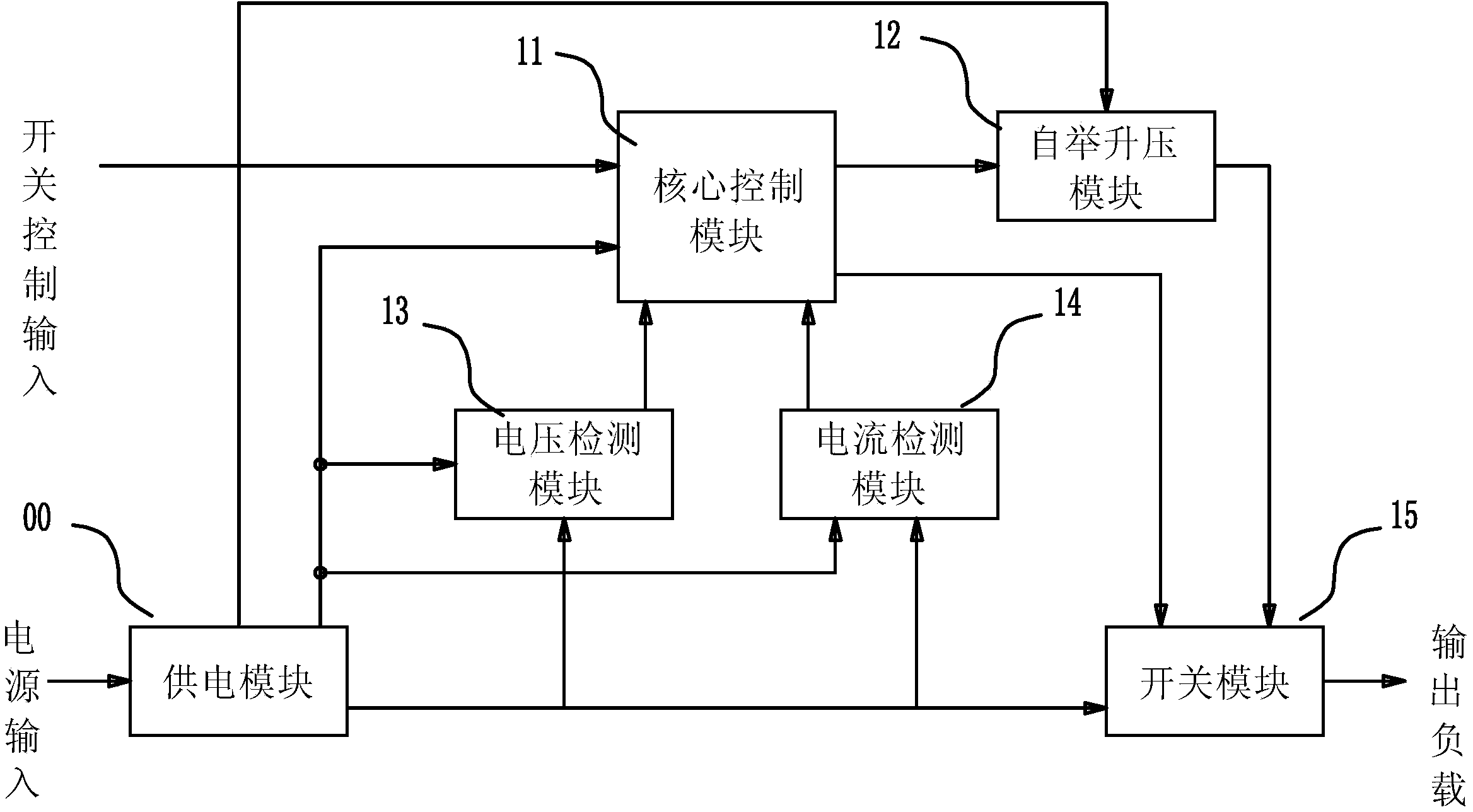

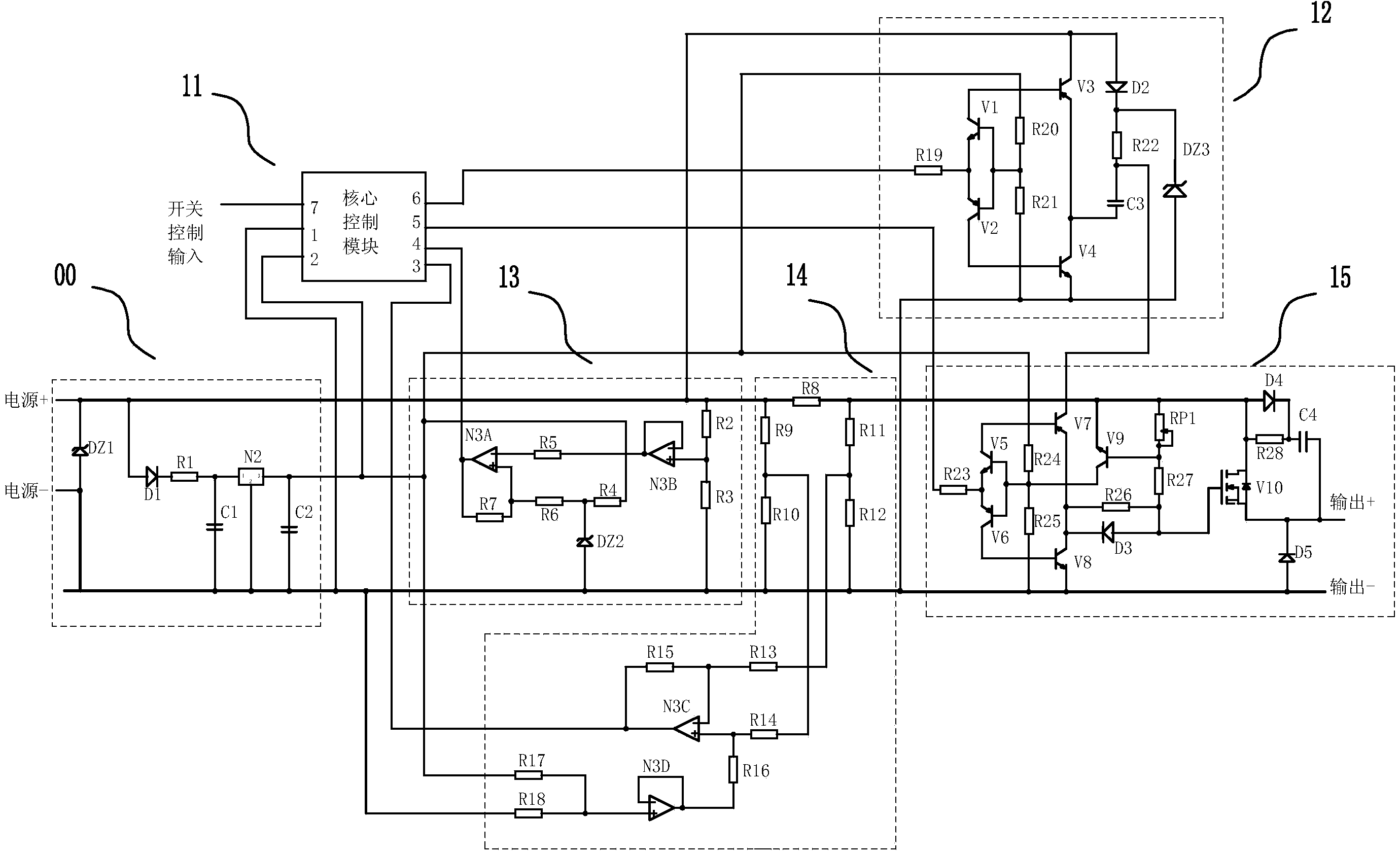

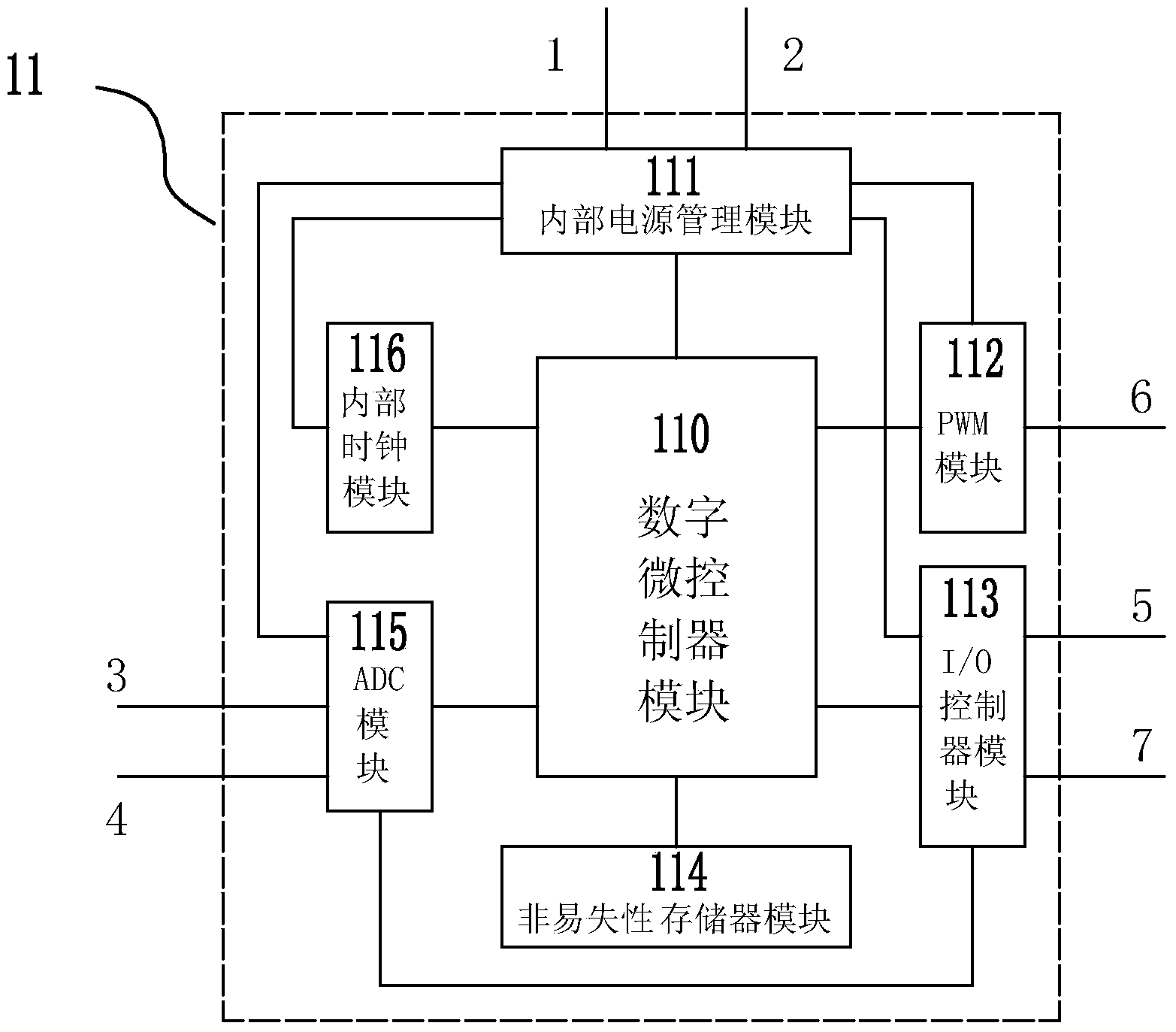

[0038] A high-efficiency intelligent high-side electronic load switch with wide voltage adaptability, the intelligent high-side electronic load switch includes a power supply module 00, a core control module 11, a bootstrap boost module 12, a voltage detection module 13, and a current detection module 14 And switch module 15; The input end interface of described core control module 11 is connected with the input end of external switch control input, voltage detection module and current detection module respectively, and its output end interface is connected with bootstrap boost module and switch module respectively; The input terminals of the voltage detection module 13 and the current detection module 14 are respectively connected with the power supply module, and the output terminals thereof are connected with the input terminal interface of the core control module;

[0039] The input end of the bootstrap boost module 12 is connected to the output port interface of the core c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com