A coal ash separation and conversion device

A conversion device, coal ash technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It is easy to maintain and maintain, the equipment is simple, and the generation of dust is suppressed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

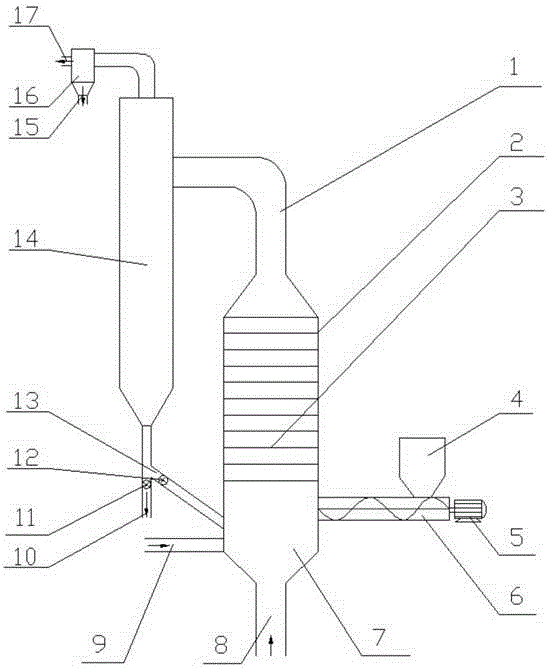

[0015] The specific implementation of a coal ash separation device of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The structure of a coal ash separation device of the present invention is as follows: figure 1 As shown, it mainly includes outlet elbow 1, cylinder body 2, collision bar 3, coal hopper 4, motor 5, screw pusher 6, coal ash separator 7, main air inlet 8, auxiliary air inlet 9, coal outlet 10 , Coal unloading valve 11, return material control valve 12, return material pipe 13, cyclone separator 14, coal ash outlet 15, bag vacuum cleaner 16, air inlet 17. A coal hopper 4, an electric motor 5, and a screw pusher 6 form a feeding device, which is installed on one side of the coal ash separator 7; a cyclone separator 14, a return pipe 13, a return control valve 12, and a coal discharge valve 11 form a coal The ash separation system is installed on the other side of the coal ash separator 7; the cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com