Method for manufacturing uniform organic and inorganic perovskite crystal film on flexible substrate

A flexible substrate and inorganic calcium technology, applied in the field of thin film preparation of planar heterostructure solar cells, can solve the problems of large contact angle, affecting the performance of planar heterojunction solar cells, and difficulty in realizing large-scale industrial production, so as to achieve excellent performance. Affected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

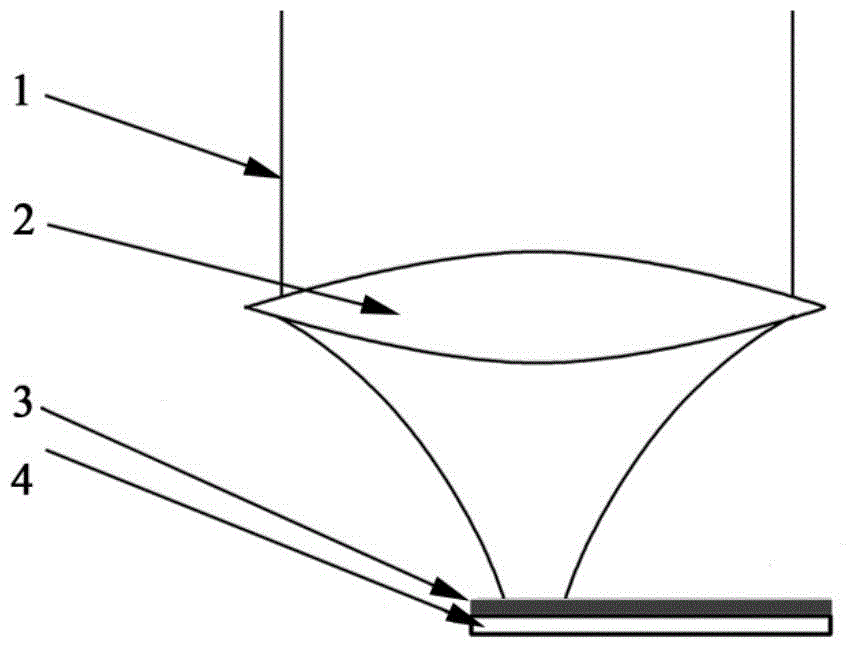

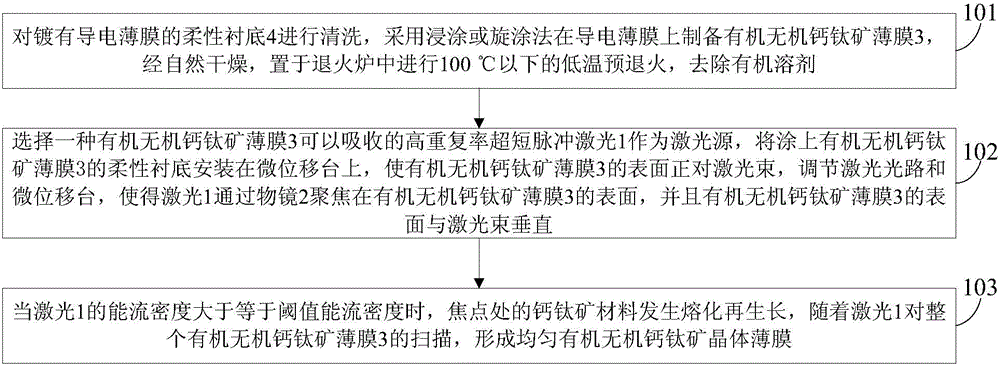

[0019] In order to improve the quality of organic-inorganic perovskite thin films on flexible substrates, embodiments of the present invention provide a method for preparing uniform organic-inorganic perovskite crystal thin films on flexible substrates, see figure 1 and figure 2 , the method includes the following steps:

[0020] 101: Clean the flexible substrate 4 coated with a conductive film, select an appropriate solvent and apply an organic-inorganic perovskite solution of appropriate concentration by dip coating or spin coating (this solvent is a composite solvent system, and the solution is prepared as A multi-step process) is coated on the conductive film to prepare the organic-inorganic perovskite film 3, which is dried naturally, placed in an annealing furnace for lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com