Preparation method of activated calcium silicate

A technology of active calcium silicate and desiliconization solution, which is applied in the direction of silicate, alkaline earth metal silicate, climate sustainability, etc., can solve the problems of reducing the average particle size of active calcium silicate particles and high content of large particles, Achieve the effect of reducing particle size, simple operation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

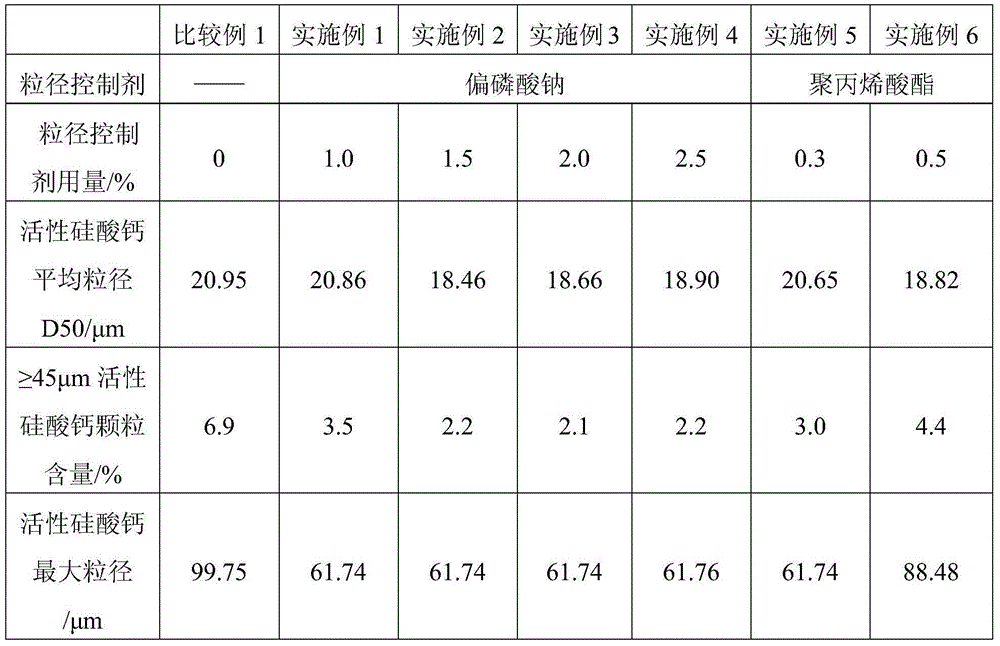

[0022] Add fly ash desiliconization liquid with a solid content of 60g / L and milk of lime with a solid content of 160g / L into the reaction tank, and mix with commercially available sodium metaphosphate for reaction to obtain active calcium silicate slurry. The molar ratio of calcium to silicon in lime milk and fly ash desiliconization liquid is 1:1, the reaction temperature is controlled at about 90°C, the reaction time is 40min, and the stirring speed can be 300r / min. The dosage of sodium metaphosphate is 1.0% of the dry weight of fly ash desiliconization liquid and milk of lime. After the reaction is completed, the obtained product slurry is sieved through a 100-mesh sieve, and then the sieved slurry is dried to obtain active calcium silicate, and the active calcium silicate is washed three times with water above 60°C to remove residual alkali.

[0023] The active calcium silicate specific surface area that the present embodiment obtains is 100-300m 2 / g, oil absorption va...

Embodiment 2

[0025] Active calcium silicate was prepared by the method in Example 1, except that the amount of sodium metaphosphate was 1.5% of the dry weight of fly ash desiliconization liquid and milk of lime.

[0026] The active calcium silicate specific surface area that the present embodiment obtains is 100-300m 2 / g, oil absorption value 150-300g / 100g, true density 1.2-1.5g / cm 3 , the bulk density is 0.15-0.30g / cm 3 , the pH value is 8-10 (tested under 20% solid content). The active calcium silicate obtained in this embodiment was tested for particle size, and the results are shown in Table 1.

Embodiment 3

[0028] Active calcium silicate was prepared by the method in Example 1, except that the amount of sodium metaphosphate was 2.0% of the dry weight of fly ash desiliconization liquid and milk of lime.

[0029] The active calcium silicate specific surface area that the present embodiment obtains is 100-300m 2 / g, oil absorption value 150-300g / 100g, true density 1.2-1.5g / cm 3 , the bulk density is 0.15-0.30g / cm 3 , the pH value is 8-10 (tested under 20% solid content). The active calcium silicate obtained in this embodiment was tested for particle size, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com