Preparation method of orange disperse dye

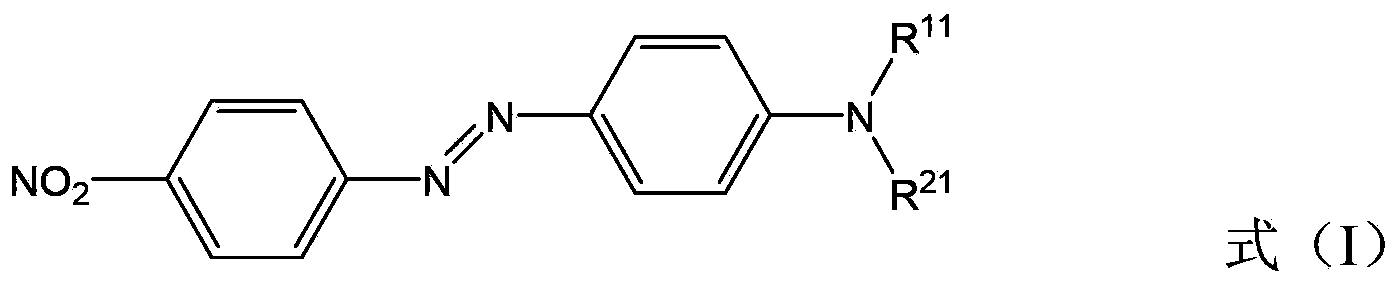

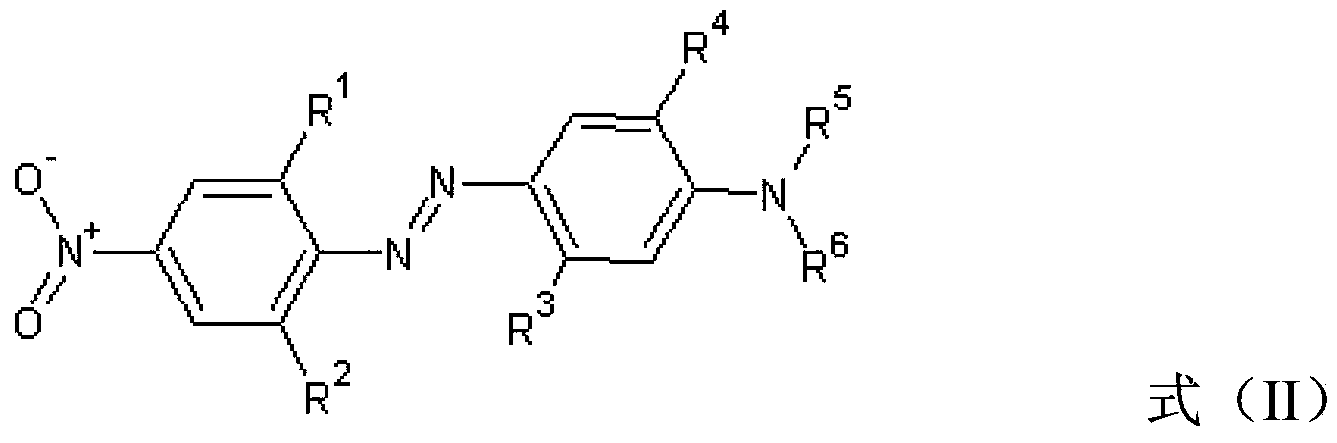

A technology of disperse dyes and mass percentage, applied in the field of preparation of orange disperse dyes, can solve the problems of containing pentachlorophenol, tetrachlorophenol, toxic substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

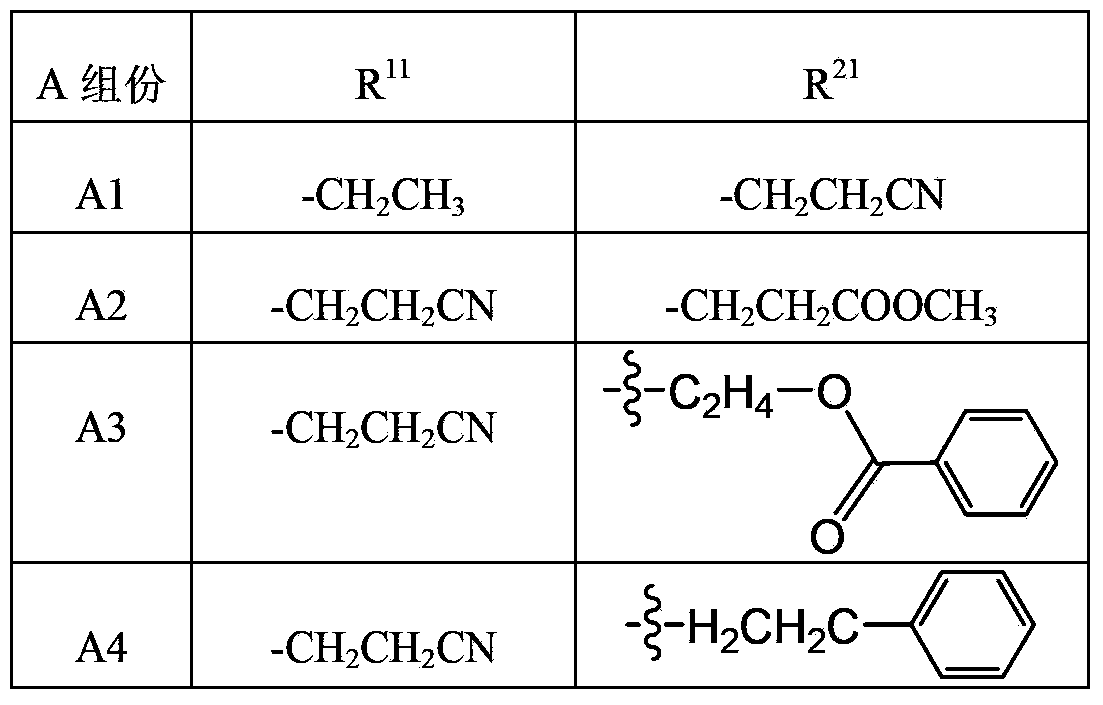

Embodiment 1

[0049] a. Weigh 19.5 grams of A4 dye, 68 grams of B1 dye, and 12.5 grams of the dye of the following formula (3), and then weigh 110 grams of auxiliary agent 85A.

[0050]

[0051] b. Add 300 grams of water, grind together in a sand mill for about 3 hours, and then spray dry. The resulting powder must be easily dispersed and dissolved in water.

[0052] c. Weigh 0.2 g of the above-obtained powder, 200 ml of water, convert it into a solution in a steel cup, adjust the pH value to between 4.5-5 with glacial acetic acid, take 10 g of polyester fiber material and put it into the prepared solution, use conventional The high temperature and high pressure dyeing process was kept at 130 °C for 50 minutes, and then the orange samples were obtained after cooling, washing, rinsing and drying.

[0053] d. The above dye powder samples and the dyed polyester fiber material samples were tested for pentachlorophenol and tetrachlorophenol, and the obtained results were all "ND".

Embodiment 2

[0055] a. Weigh 31.5 g of A3 dye, 68.4 g of B1 dye, 0.1 g of B6 dye, and 100 g of auxiliary agent 85A.

[0056] Repeating the above b, c, d operations, the dye powder samples and the dyed orange polyester fiber material samples were tested for pentachlorophenol and tetrachlorophenol, and the obtained results were all "ND".

Embodiment 3

[0058] a. Weigh 45.73 grams of A4 dye, 54.27 grams of B1 dye, and 100 grams of auxiliary agent 85A.

[0059] Repeating the above b, c, d operations, the dye powder samples and the dyed orange polyester fiber material samples were tested for pentachlorophenol and tetrachlorophenol, and the obtained results were all "ND".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com