Gas steam combined cycle unit multivariable constrained prediction function load control method

A combined cycle unit and prediction function technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as difficulty in raising and lowering load rate, difficult application engineering, fluctuation of main steam pressure of steam turbine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

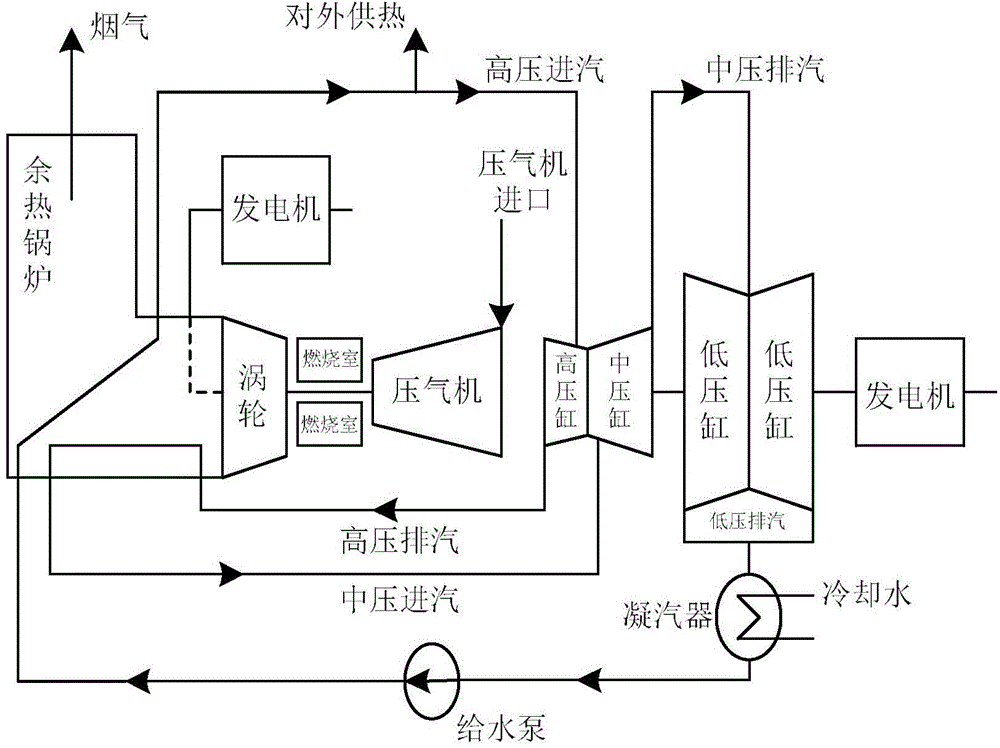

[0049] The 180MW gas-steam combined cycle unit of a certain power plant is improved by using the present invention, so as to cope with the newly formulated unit raising and lowering rate standards. The specific implementation process is as follows:

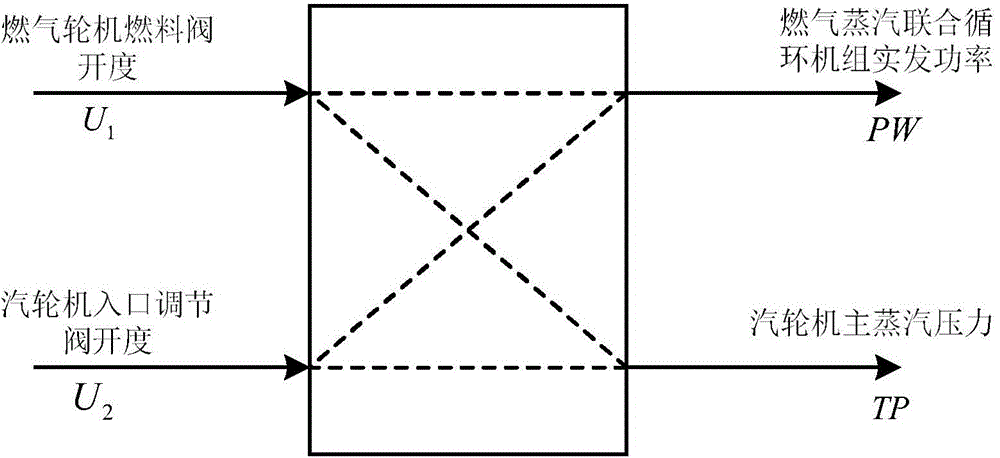

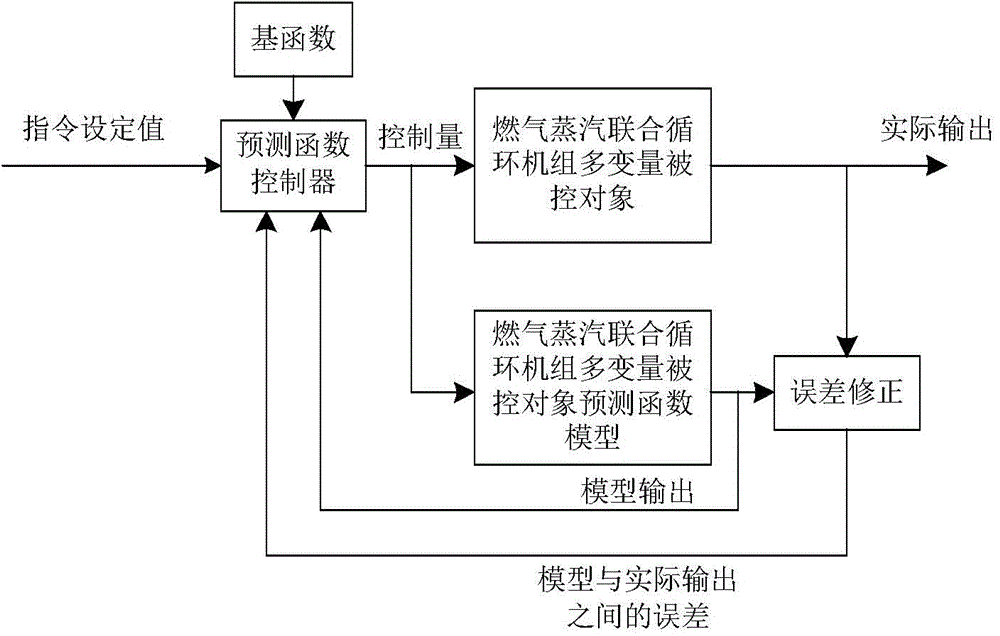

[0050] Its traditional gas-steam combined cycle unit uses a control system consisting of three parts: temperature control loop, speed control loop and acceleration control loop. Here, a multi-variable controlled object model is directly established in which the fuel valve of the gas turbine and the inlet regulating valve of the steam turbine are taken as the input, and the actual power of the combined cycle unit and the main steam pressure of the steam turbine are taken as the output, and the speed and exhaust gas temperature of the gas turbine are only considered as safety factors. At the same time, adjust the frequency modulation command once and superimpose it on the gas turbine load command.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com