Perovskite solar cell based on full-sol-gel process and preparation method thereof

A solar cell and sol-gel technology, which is applied in the field of solar photovoltaic utilization, can solve the problems of complex manufacturing process and high cost, and achieve the effects of simplifying the manufacturing process, reducing manufacturing costs, and facilitating large-area manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the drawings and embodiments. The following examples are used to illustrate the present invention, but cannot be used to limit the scope of the present invention.

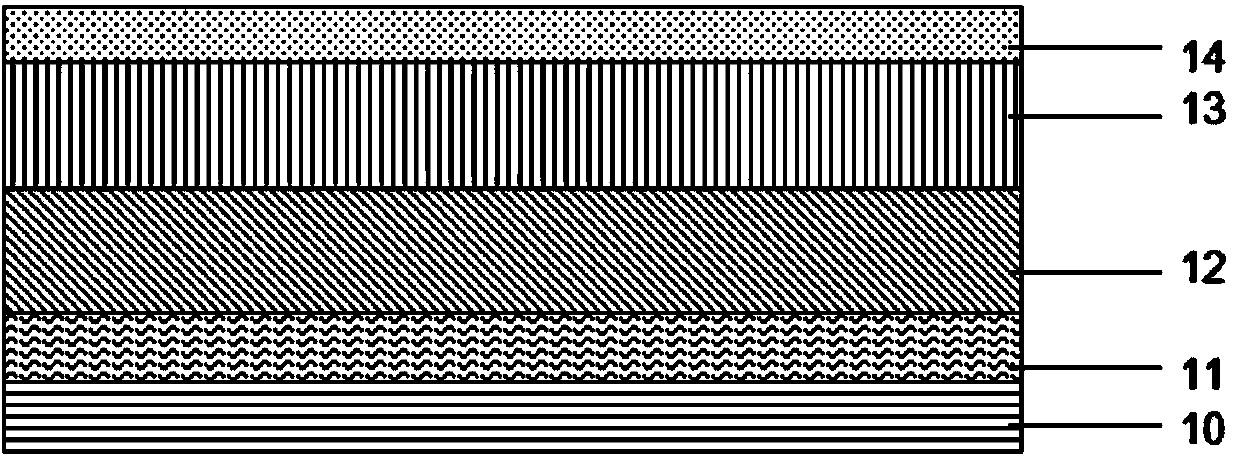

[0037] figure 1 It is a schematic diagram of the structure of a perovskite solar cell based on the all-sol-gel process of the present invention; the perovskite solar cell based on the all-sol-gel process of the present invention is from top to bottom using the Nippon Sheet Glass company of Japan FTO (F-doped tin oxide) conductive glass substrate 14, metal oxide layer 13, perovskite film layer 12, hole transport layer 11, back electrode contact layer 10; the back electrode contact layer 10 is indium tin oxide ITO layer; the metal oxide layer 13 is BaTiO 3 Layer, ZnO layer or SnO 2 Layer; The perovskite film layer 12 is CH 3 NH 3 PbI 3 Layer, CH 3 NH 3 PbBr 3 Layer or CH 3 NH 3 PbCl 3 Layer; The hole transport layer 11 is 2,2',7,7'...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com