Controlling method of shape-locking cooking of frying and baking machine, and frying and baking machine

A control method and technology of a frying and roasting machine, which are applied in frying pans, household appliances, applications, etc., can solve the problems of collapse, zooming, and difficulty in shaping of ingredients, and achieve the effects of improving the molding effect, improving the cooking effect, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

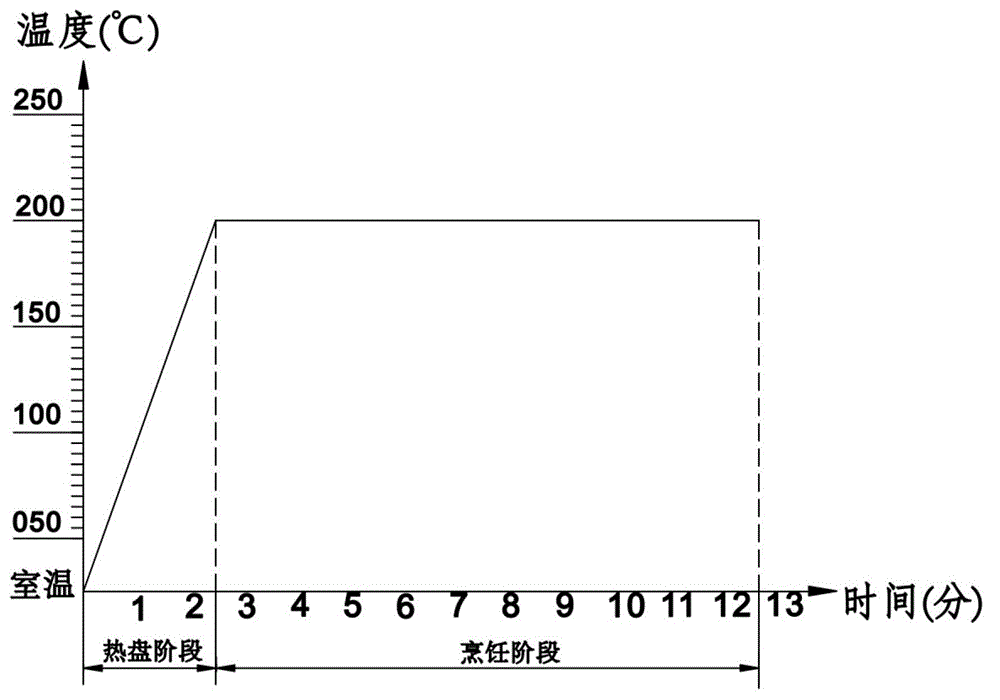

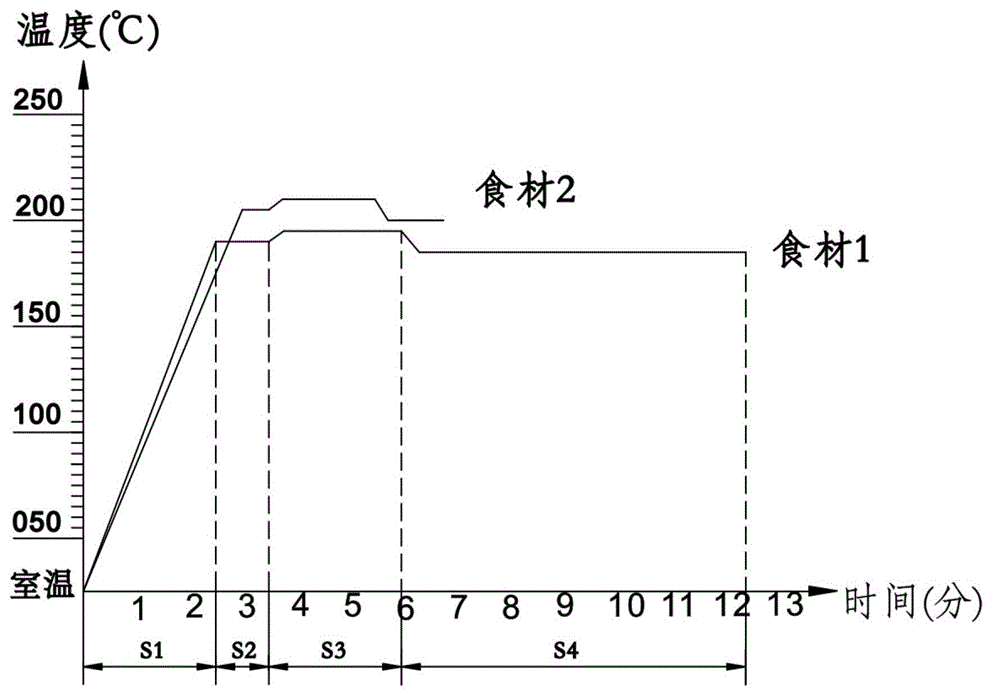

[0026] A control method for lock-type cooking of a frying and roasting machine, the frying and roasting machine includes a heating element and a baking tray, such as figure 2 , the method includes:

[0027] Hot plate stage S1: Control the heating element to heat the grill pan to the temperature of the hot oil, so as to realize the hot plate on the grill pan before cooking the ingredients;

[0028] Oil heating stage S2: After the user heats the cooking oil in the baking pan, the heating element is controlled to heat the cooking oil added to the baking pan and maintain the temperature of the hot oil to achieve full heating of the oil;

[0029] Locking stage S3: After the user adds cooking ingredients to the baking pan, control the heating element to heat the baking pan to the locking temperature to lock the cooking ingredients, and heat up the baking pan to lock the cooked ingredients;

[0030] Cooking stage S4: Control the heating element to reduce the heating power or contro...

Embodiment 2

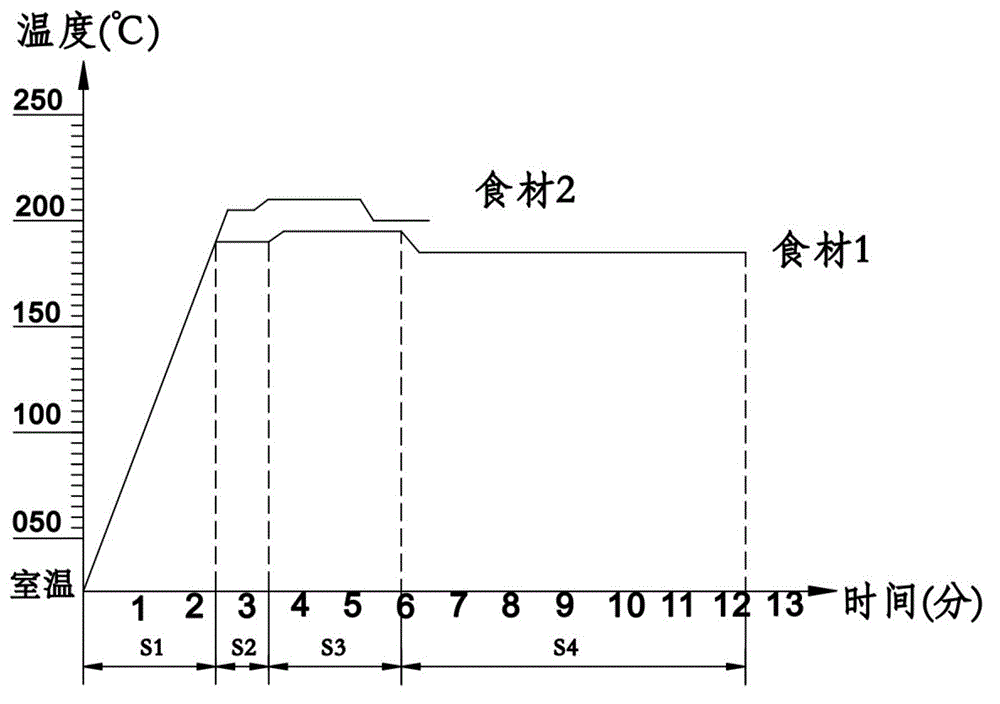

[0036] The difference between this embodiment and the first embodiment is that, if image 3 , in the hot plate stage S1, the curvature of the heating temperature curve for different ingredients is the same, that is, the heating element still uses the same heating power for different ingredients in the hot plate stage S1, but according to the different ingredients, the corresponding hot oil temperature, lock The cooking temperature and the cooking temperature are different. This setting avoids frequent changes in the power of the heating element when cooking different ingredients, simplifies the program setting of the cooking process, and prolongs the service life of the heating element.

[0037] Example of frying machine:

[0038]A frying and roasting machine adopting the above control method, the frying and roasting machine includes a heating element and a grill pan, the said frying and roasting machine is provided with a main controller 1 and a temperature sensor, the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com