Reflux oil distribution device in washing section of distillation tower

A distribution device and distillation tower technology, applied in the direction of vacuum distillation, etc., can solve the problems of increasing the number of pumps and power consumption, increasing heat loss, increasing manufacturing costs, etc., to improve reliability, reduce production and operation costs, and reduce equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

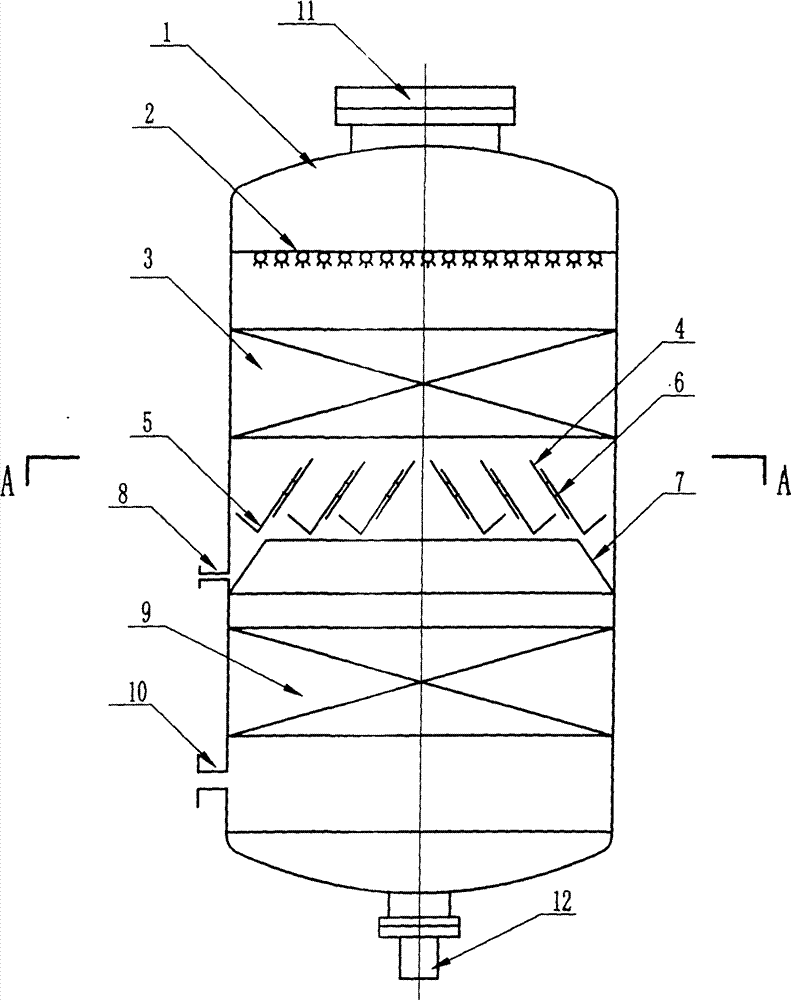

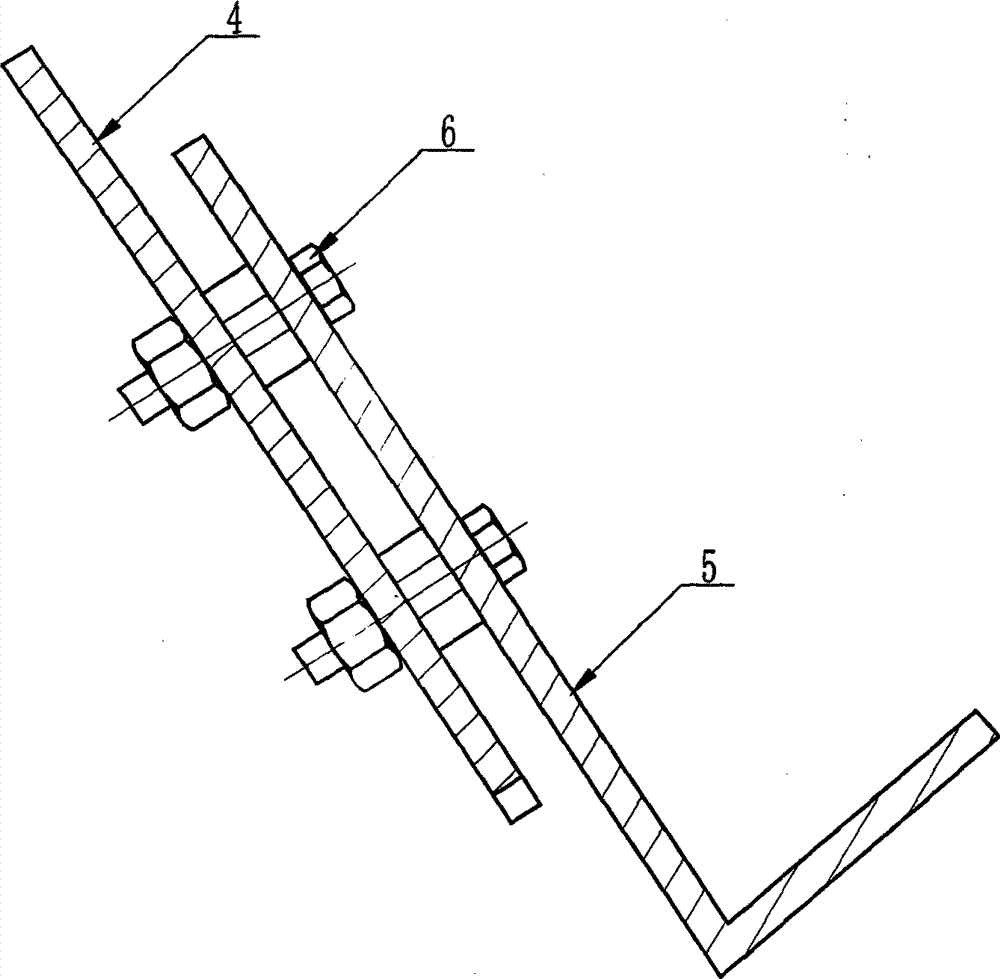

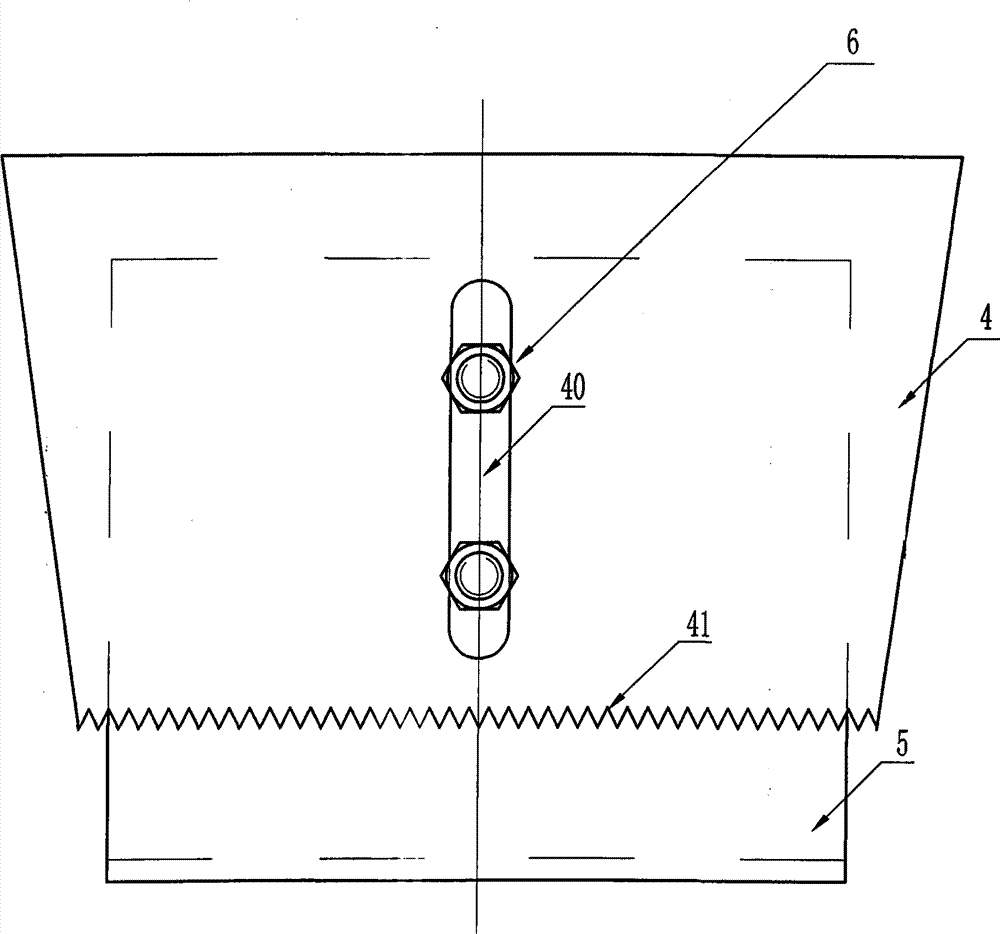

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the reflux oil distribution device in the washing section of the distillation tower of the present invention includes a distillation tower 1, a reflux oil distributor 2, a packing condensation section 3, a splitter plate 4, an "L"-shaped long plate 5, an annular collection tank 7, and an oil outlet 8. Packing washing section 9; reflux oil distributor 2 is fixed on the inner wall near the upper end of distillation tower 1; packing condensing section 3 is arranged below reflux oil distributor 2; multiple shunt plates 4 are arranged below packing condensing section 3 to divert The plate 4 is fixed on the side wall of the distillation tower 1; each splitter plate 4 is provided with a long groove 40, and the "L" shaped long plate 5 is fixed on the splitter plate 4 by the bolt 6 arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com