A photolithographic method for preparing affinity-phobic patterns

A pattern and affinity technology, which is applied in the field of photolithography for preparing affinity patterns, can solve the problems of complex photolithography process, limit the use range of photolithography technology, and the size of graphics, and achieve the effects of wide application prospects, energy saving, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

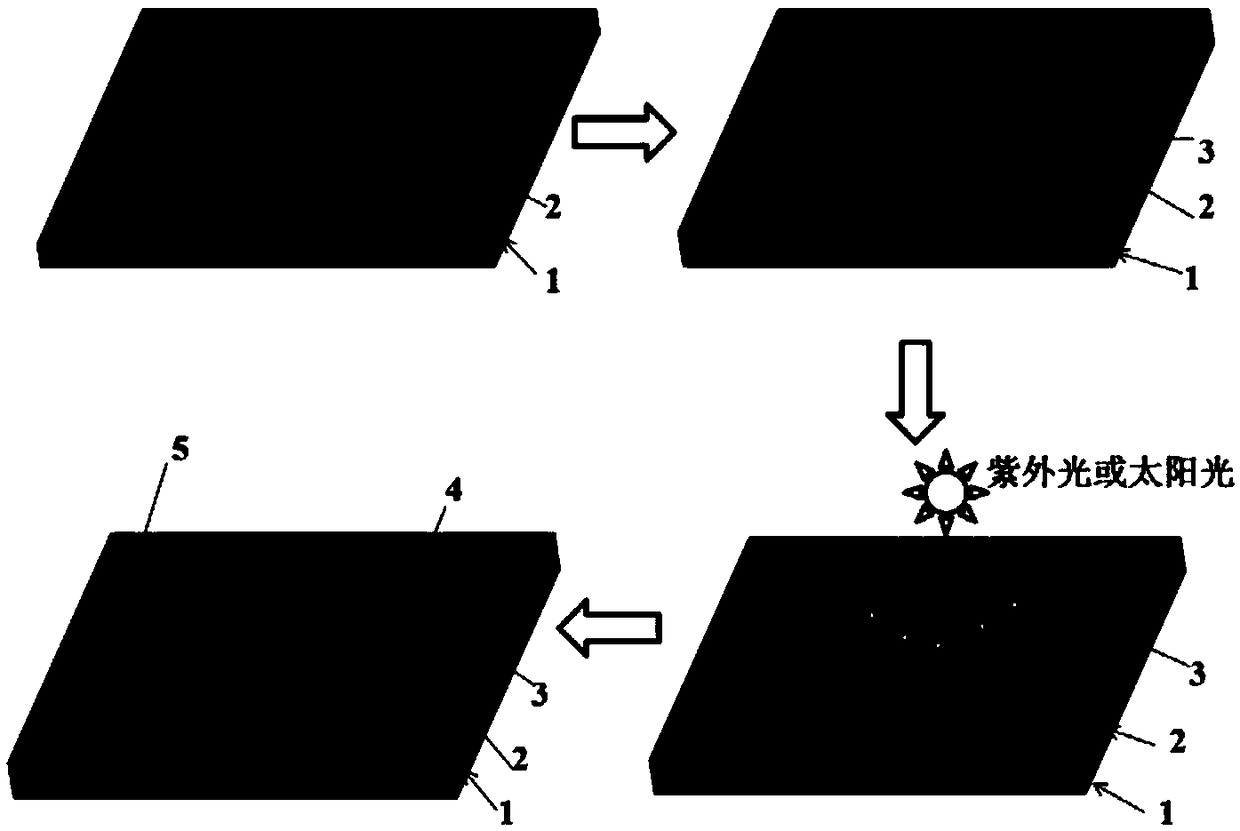

[0016] like figure 1 A photolithography method for preparing an affinity-phobic pattern is shown, the method comprises the following steps: first, on a glass substrate 1, a dispenser is used to coat or spray a layer of organic silica gel pattern connection layer 2 with a point-like structure pattern; Coat, spray or spin coat a layer of surface coating 3, and finally irradiate with ultraviolet light for 5 minutes to obtain a hydrophilic pattern. The bottom is coated with organic silica gel as a hydrophobic region, and the bottom directly as a glass substrate is a hydrophilic region; The surface coating 3 is micro-nano titanium dioxide particles whose surface is modified with tridecafluorotriethoxyoctylsilane; the titanium dioxide particles are particles with a composite size of 25 nm and 1 μm.

Embodiment 2

[0018] refer to figure 1 , the photolithographic method for preparing the affinity pattern comprises the following steps: firstly, on the stainless steel substrate 1, a pattern connection layer 2 of polydimethylsiloxane with a linear pattern is printed by screen printing; secondly, coating, spraying or spinning Apply a layer of surface coating, and finally irradiate with sunlight for 5 minutes to obtain a hydrophilic and hydrophobic pattern. The bottom is coated with polydimethylsiloxane as a hydrophobic region, and the bottom is directly on the stainless steel substrate as a hydrophilic region; the surface The coating is 120nm micronano titanium dioxide particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com