Selective electrode type solar cell grid line printing position precision detecting method

A solar cell and printing position technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of harsh environmental requirements, light pollution, and the inability to detect the coincidence accuracy of the printing area of metal grid lines and heavy diffusion grid lines, etc., to achieve The effect of reducing production costs and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

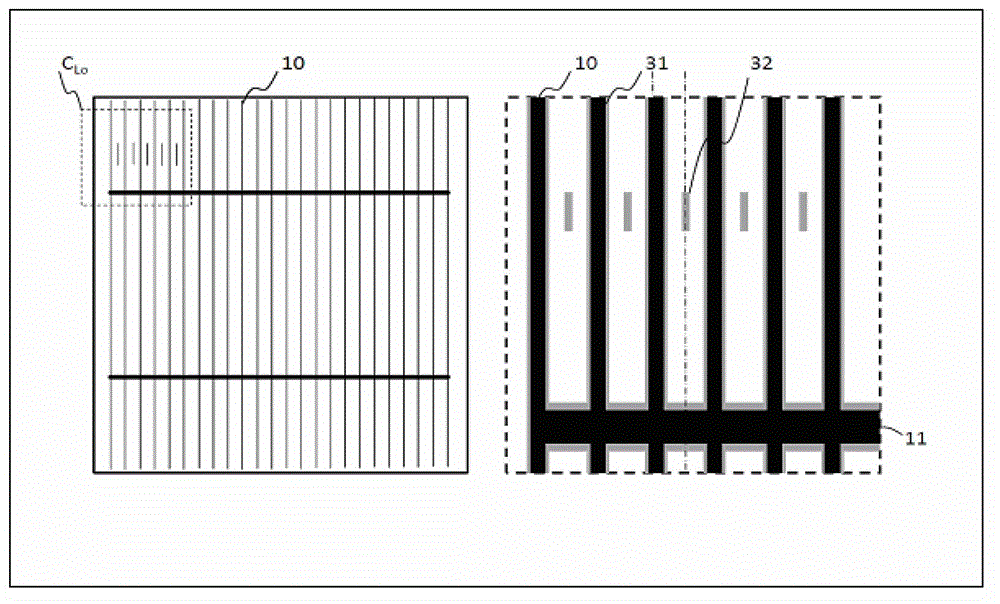

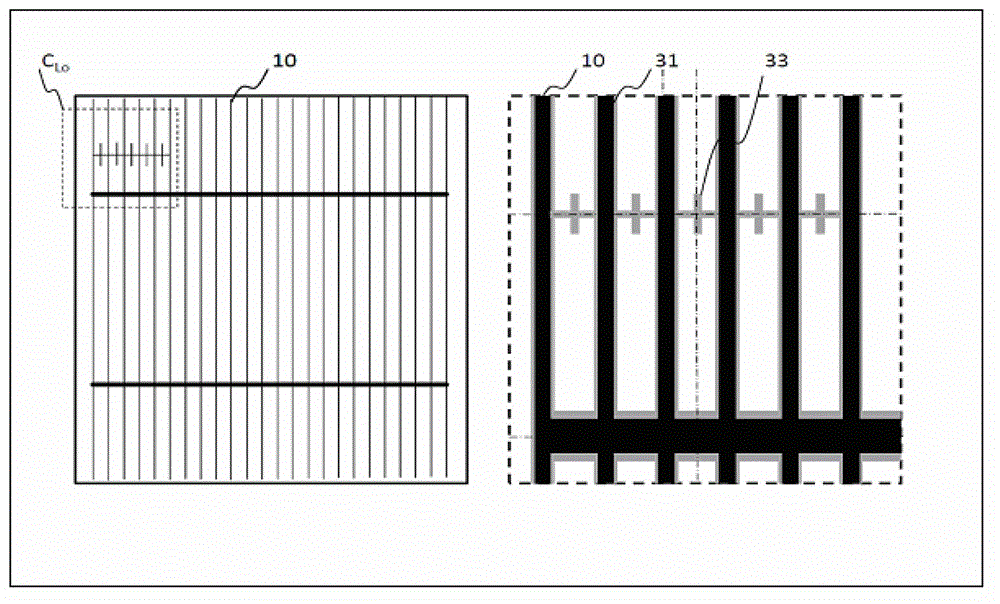

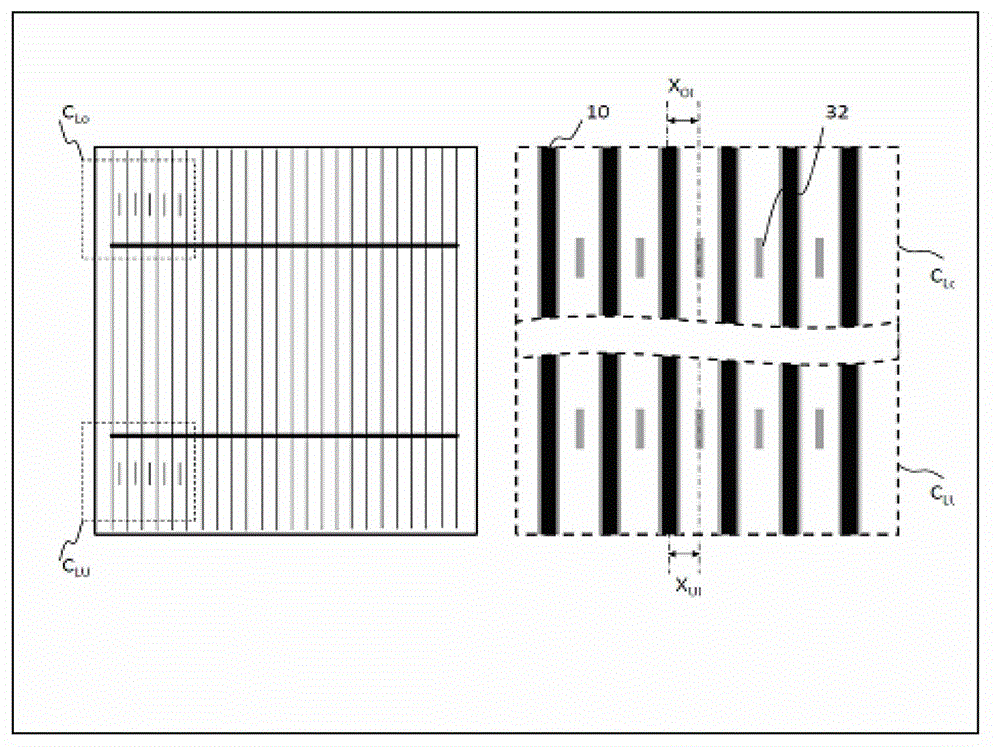

[0039] refer to figure 1 , figure 2 , image 3 with Figure 4 , the detection method of the printing position accuracy of the grid lines of selective electrode type solar cells, a mark pattern is generated on the light-receiving surface of the battery sheet, and after the metal grid line is printed, the distance between the metal grid line and the mark pattern is measured, and the mark pattern and the mark pattern are combined. The distance from the center line of the selective re-diffusion area determines the coincidence accuracy of the grid line printing position and the selective re-diffusion area. The method can detect the coincidence accuracy of the printing position of the metal grid line and the selective re-diffusion area, that is, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com