A kind of advanced treatment method of excess sludge

A technology for excess sludge and advanced treatment, which is applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc. It can solve problems such as high organic matter content, large amount of conditioner, and restrictions on sludge disposal. Achieve the effects of reducing the cost of chemicals, reducing the content of organic matter, reducing construction costs and operation management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

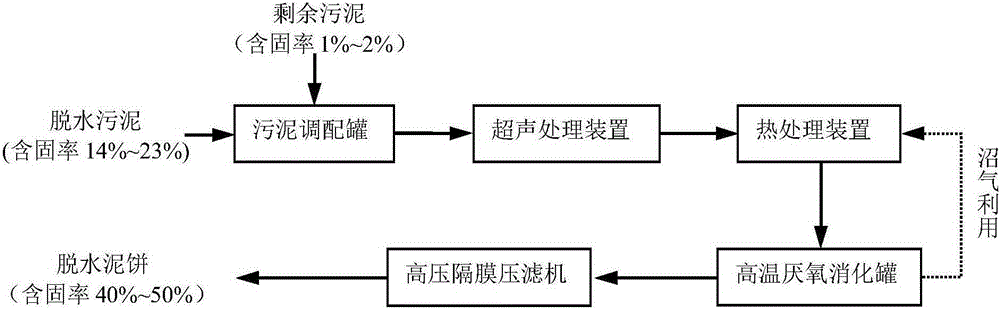

Method used

Image

Examples

Embodiment 1

[0029] 1. Sludge preparation: the dewatered sludge (taken from the sludge dewatering room of the sewage treatment station of Shandong New Times Pharmaceutical Co., Ltd., with a solid content of 14%, a pH of 6.8, and organic components in the solids accounting for 53%) and the remaining sludge (The sludge concentration tank of the sewage treatment station of Shandong New Times Pharmaceutical Co., Ltd. has a solid content of 2%, a pH of 6.9, and organic components in the solids account for 57%) to the sludge blending tank at a weight ratio of 1:1. Mixed sludge (8% solid content, 6.8 pH, 54% organic components in solids) was obtained after stirring and mixing.

[0030] 2. Pretreatment: The mixed sludge first passes through the ultrasonic treatment device, the ultrasonic treatment frequency is 40kHz, and the treatment time is 10min; then it enters the heat treatment device, the heat treatment temperature is 55°C, and the treatment time is 3.0h.

[0031] 3. High-temperature anaerob...

Embodiment 2

[0034] 1. Sludge deployment: Combine dewatered sludge (Shandong New Times Pharmaceutical Co., Ltd. sewage treatment station sludge dehydration room, solid content 19%, pH 6.7, organic components in solids account for 55%) and excess sludge (Shandong The sludge thickening tank of the sewage treatment station of New Times Pharmaceutical Co., Ltd., with a solid content of 1%, a pH of 6.9, and organic components in the solids account for 58%) is added to the sludge blending tank at a weight ratio of 1:1, and is fully stirred by mechanical stirring. After mixing, mixed sludge (10% solid content, pH 6.8, 55% organic components in solids) was obtained.

[0035] 2. Pretreatment: The mixed sludge first passes through the ultrasonic treatment device, the ultrasonic treatment frequency is 20kHz, and the treatment time is 60min; then it enters the heat treatment device, the heat treatment temperature is 70°C, and the treatment time is 1.0h.

[0036] 3. High-temperature anaerobic digestion...

Embodiment 3

[0039] 1. Sludge preparation: The raw sludge (taken from the sludge dehydration room of the sewage treatment station of Shandong New Times Pharmaceutical Co., Ltd., with a solid content of 23%, a pH of 7.0, and organic components in the solids accounting for 56%) and the remaining sludge (The sludge concentration tank of the sewage treatment station of Shandong New Times Pharmaceutical Co., Ltd. has a solid content of 2%, a pH of 6.9, and organic components in the solid account for 61%). Mixed sludge (9% solid content, 6.9 pH, 57% organic components in solids) was obtained after stirring and mixing.

[0040] 2. Pretreatment: The mixed sludge first passes through the ultrasonic treatment device, the ultrasonic treatment frequency is 28kHz, and the treatment time is 30 minutes; then it enters the heat treatment device, the heat treatment temperature is 60°C, and the treatment time is 2 hours.

[0041] 3. High-temperature anaerobic digestion: The pretreated sludge enters the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com