Modified carbamide, micromolecule active organic matter and preparation method for modified carbamide

A technology for modifying urea and organic matter, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of failure to obtain the best technical effect, no detailed research, etc., and achieve the goals of reducing volatilization, enhancing absorption, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

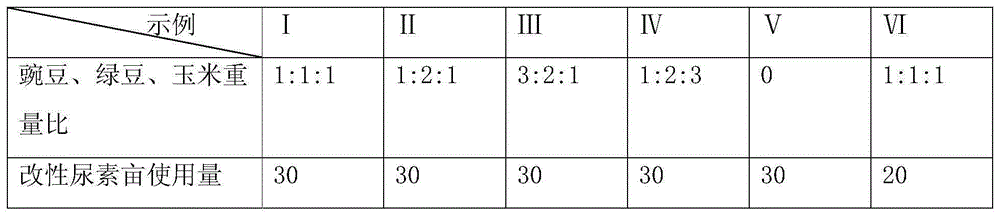

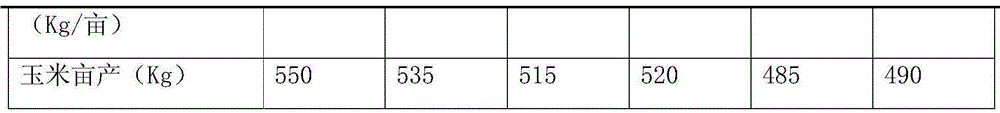

Examples

Embodiment 1

[0042] A small molecule active organic matter, the preparation method of which is as follows:

[0043] Put 100kg of peas, 100kg of mung beans, and 100kg of corn into a large reaction tank, add 1800L (6 times the weight) of water at a temperature of 40°C and soak for 10 hours, stir and pulverize, and filter out the water to obtain the filter residue;

[0044] Add 2 times the weight of the phosphate buffer solution with a pH of 6 to the filter residue, add 1% of the weight of the filter residue to ferment for 2 days at room temperature, and stir the fermented product once a day;

[0045]After the fermentation is over, filter out the fermentation broth, pass the fermentation broth through a D-85 macroporous propionate-based weakly acidic cation exchange resin, elute with 5 times the column volume of water, and collect the 2 times and 3 times the amount of eluate that flows out , the eluate was adjusted to pH 6, concentrated and dried to obtain 3 kg of small molecule active organi...

Embodiment 2

[0051] A small molecule active organic matter, the preparation method of which is as follows:

[0052] Put 50kg of peas, 100kg of mung beans, and 100kg of corn into a large reaction tank, add 2500L (10 times the weight) of water at a temperature of 60°C and soak for 5 hours, stir and pulverize, and filter out the water to obtain a filter residue;

[0053] Add 1 times the weight of the phosphate buffer solution with a pH of 5 to the filter residue, add 1% of the weight of the filter residue to ferment at room temperature for 1 day, and stir the fermented product once a day;

[0054] After the fermentation is over, filter out the fermentation broth, pass the fermentation broth through a D-85 macroporous propionate-based weakly acidic cation exchange resin, elute with 5 times the column volume of water, and collect the 2 times and 3 times the amount of eluate that flows out , the eluate was adjusted to a pH value of 6, concentrated and dried to obtain 2.5 Kg of small molecule act...

Embodiment 3

[0056] A small molecule active organic matter, the preparation method of which is as follows:

[0057] Put 150kg of peas, 100kg of mung beans, and 50kg of corn into a large reaction tank, add 1500L (5 times the weight) of water at a temperature of 30°C and soak for 20 hours, stir and pulverize, and filter out the water to obtain a filter residue;

[0058] Add 2 times the weight of the phosphate buffer solution with a pH of 7 to the filter residue, add 1% of the weight of the filter residue to ferment for 5 days at room temperature, and stir the fermented product once a day;

[0059] After the fermentation is over, filter out the fermentation broth, pass the fermentation broth through a D-85 macroporous propionate-based weakly acidic cation exchange resin, elute with 5 times the column volume of water, and collect the 2 times and 3 times the amount of eluate that flows out , the eluate was adjusted to a pH value of 6, concentrated and dried to obtain 3.2 Kg of small molecule ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com