Brewing method used for fermenting tartary buckwheat wine through mixing Daqu and Xiaoqu

A technology of mixed fermentation and tartary buckwheat wine, which is applied in the field of liquor brewing, can solve the problems of long production cycle, single nutrient composition and low acid ester content of Daqu wine, and achieve a shortened fermentation period, rich nutrient composition and high acid ester content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

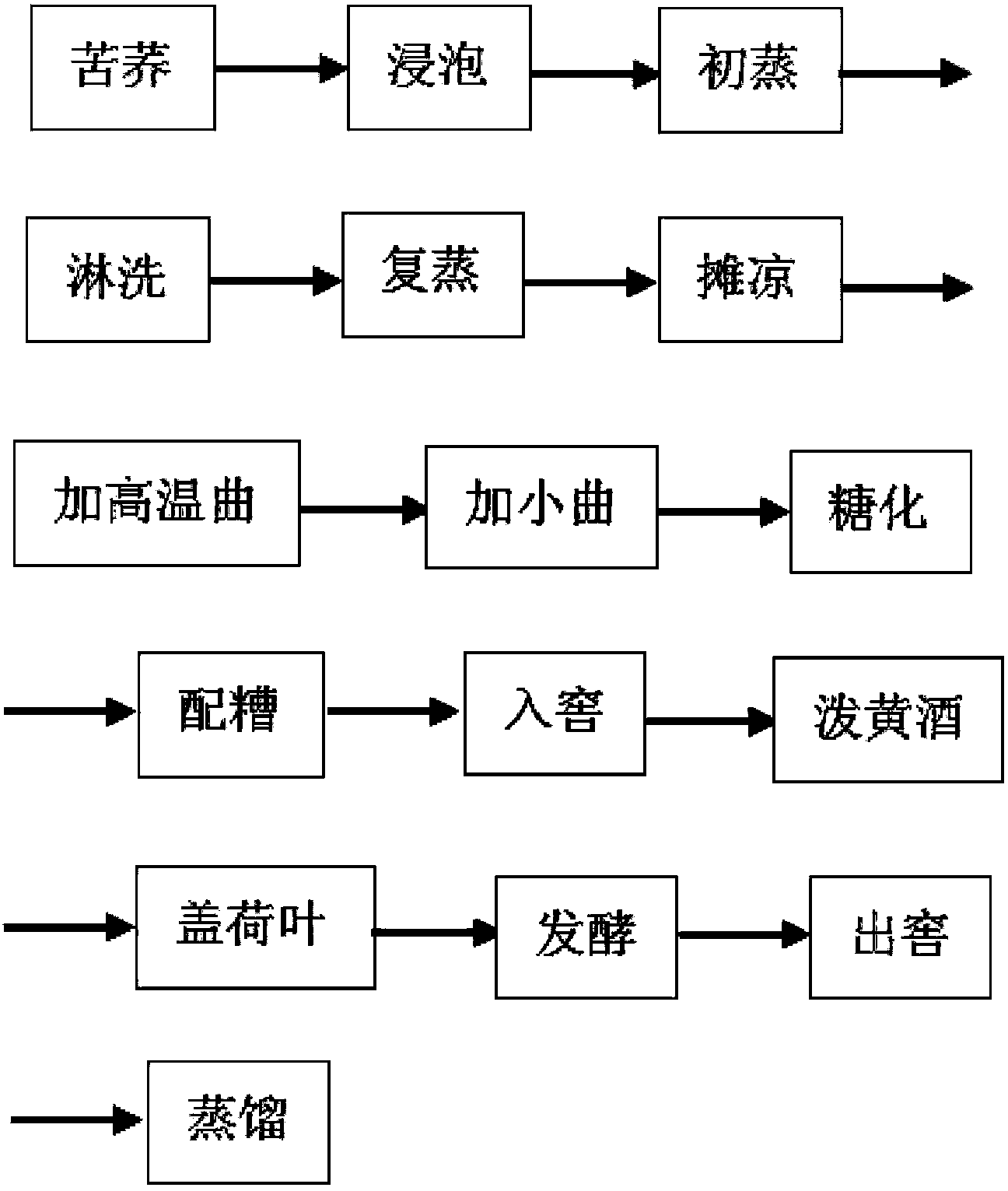

Method used

Image

Examples

Embodiment 1

[0040] (1) Tartary buckwheat soaking: Take 750kg of tartary buckwheat produced in Weining, Guizhou, and soak it in a water temperature of 15°C for 24 hours in a grain soaking box, and the water level is 30cm higher than the tartary buckwheat noodles.

[0041] (2) Initial steaming: transport the soaked tartary buckwheat to a steamer, steam the tartary buckwheat until the tartary buckwheat husks are opened.

[0042] (3) Rinse: Turn off the steam, rinse the tartary buckwheat with water, and stir while rinsing to remove dust and other sundries on the tartary buckwheat.

[0043] (4) Re-steaming: turn on the steam again, and steam until the tartary buckwheat husk is half opened.

[0044] (5) Cooling: Use a trolley to transport the steamed buckwheat to the cooling bed, and turn on the blower to cool down.

[0045] (6) Adding high-temperature koji: when the temperature drops to 50°C, add 7.5 kg of high-temperature koji and mix well.

[0046] (7) Adding Xiaoqu: when the temperature d...

Embodiment 2

[0059] (1) Tartary buckwheat soaking: Take 850 kg of tartary buckwheat produced in Weining, Guizhou, and soak it in a water temperature of 20°C for 19 hours in a grain soaking box, and the water level is 35cm higher than the tartary buckwheat noodles.

[0060] (2) Initial steaming: transport the soaked tartary buckwheat to a steamer, steam the tartary buckwheat until the tartary buckwheat husks are opened.

[0061] (3) Rinse: Turn off the steam, rinse the tartary buckwheat with water, and stir while rinsing to remove dust and other sundries on the tartary buckwheat.

[0062] (4) Re-steaming: turn on the steam again, and steam until the tartary buckwheat husk is half opened.

[0063] (5) Cooling: Use a trolley to transport the steamed buckwheat to the cooling bed, and turn on the blower to cool down.

[0064] (6) Add high-temperature koji: when the temperature drops to 52°C, add 34kg high-temperature koji and mix well.

[0065] (7) Add Xiaoqu: when the temperature drops to 47...

Embodiment 3

[0078] (1) Tartary buckwheat soaking: Take 800kg of tartary buckwheat produced in Weining, Guizhou, and soak it in a water temperature of 17°C for 22 hours in a grain soaking box, and the water level is 33cm higher than the tartary buckwheat noodles.

[0079] (2) Initial steaming: transport the soaked tartary buckwheat to a steamer, steam the tartary buckwheat until the tartary buckwheat husks are opened.

[0080] (3) Rinse: Turn off the steam, rinse the tartary buckwheat with water, and stir while rinsing to remove dust and other sundries on the tartary buckwheat.

[0081] (4) Re-steaming: turn on the steam again, and steam until the tartary buckwheat husk is half opened.

[0082] (5) Cooling: Use a trolley to transport the steamed buckwheat to the cooling bed, and turn on the blower to cool down.

[0083] (6) Add high-temperature koji: when the temperature drops to 48°C, add 21.3kg high-temperature koji and mix well.

[0084] (7) Add Xiaoqu: when the temperature drops to 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com