Surface treatment roughening process for electronic copper foils

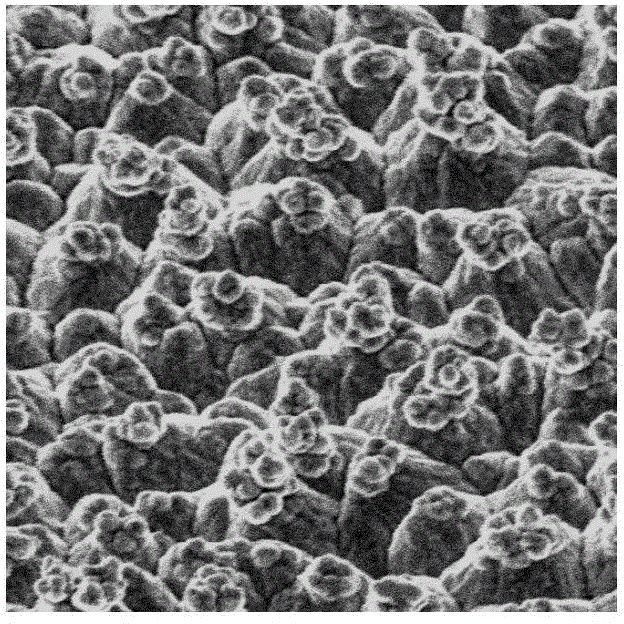

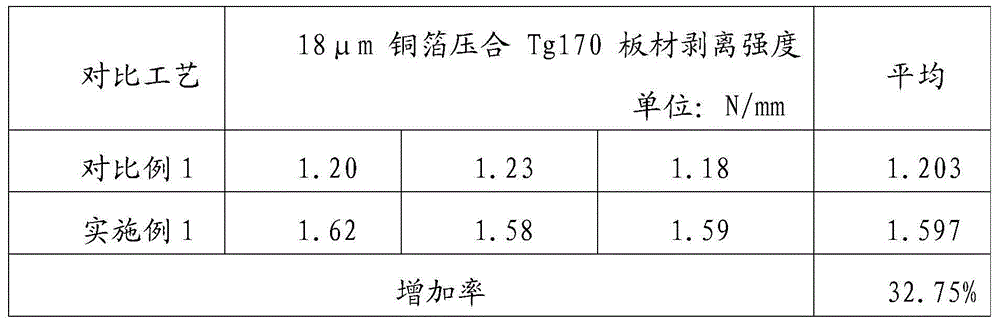

A technology of surface treatment and electronic copper foil, which is applied in the field of copper foil surface treatment production, can solve the problems that the anti-peel strength has not been significantly improved and the operation is complicated, and achieve the effect of excellent peel strength, high specific surface area and low peak value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A roughening process for surface treatment of 18 μm electronic copper foil, the steps are as follows:

[0020] (1) Mix and dissolve cathode copper and concentrated sulfuric acid to prepare a roughening solution; wherein, Cu 2+ :20g / L,H 2 SO 4 : 80g / L, the temperature of the roughening solution is 25°C;

[0021] (2) The roughening solution obtained in step (1) is fully mixed and then enters the roughening tank, followed by electroplating with high current density, medium current density and low current density, wherein the high current density is 140A / dm 2 , the plating time is 6s; the medium current density is 70A / dm 2 , the electroplating time is 6s; the low current density is 30A / dm 2 , The electroplating time is 4.5s.

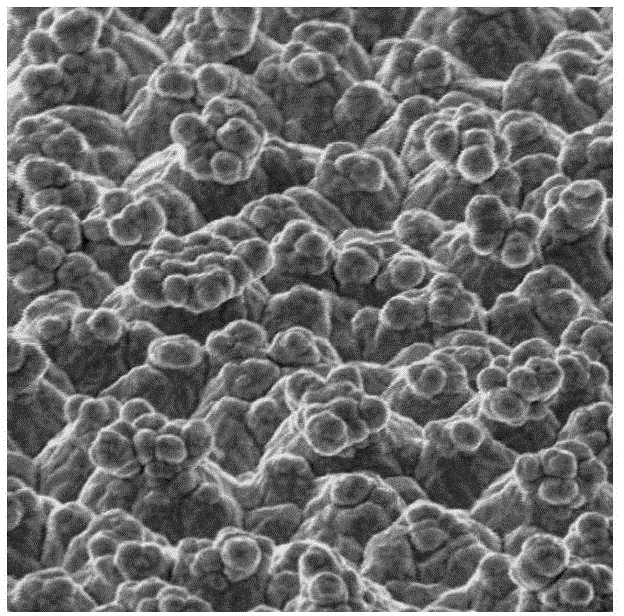

[0022] figure 2 It is the SEM spectrum of the surface roughening effect of the copper foil using Example 1 of the present invention.

[0023] Will figure 1 with figure 2 For comparison, it can be seen that figure 2 The roughened layer of ...

Embodiment 2

[0029] A surface treatment roughening process for electronic copper foil, the steps are as follows:

[0030] (1) Mix and dissolve cathode copper and concentrated sulfuric acid to prepare a roughening solution; wherein, Cu 2+ :40g / L, H 2 SO 4 : 150g / L, the temperature of the roughening solution is 40°C;

[0031] (2) Mix the roughening solution obtained in step (1) fully and then enter the roughening tank, and conduct electroplating through high current density, medium current density and low current density in turn, wherein the high current density is 200A / dm 2 , the plating time is 6s; the medium current density is 90A / dm 2 , the electroplating time is 4.5s; the low current density is 50A / dm 2 , The electroplating time is 6s.

Embodiment 3

[0033] A surface treatment roughening process for electronic copper foil, the steps are as follows:

[0034] (1) Mix and dissolve cathode copper and concentrated sulfuric acid to prepare a roughening solution; wherein, Cu 2+ :30g / L, H 2 SO 4 : 100g / L, the temperature of the roughening solution is 35°C;

[0035] (2) After fully mixing the roughening solution obtained in step (1), enter the roughening tank, and conduct electroplating through high current density, medium current density and low current density in turn, wherein the high current density is 160A / dm 2 , the plating time is 4.5s; the medium current density is 80A / dm 2 , the plating time is 6s; the low current density is 40A / dm 2 , The electroplating time is 6s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com