Impedance frequency select surface

A frequency-selective surface and resistance technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of restricted housing structure shape, steep frequency selection characteristics, etc., to achieve design and effective reduction, increase design freedom , the effect of low backscattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

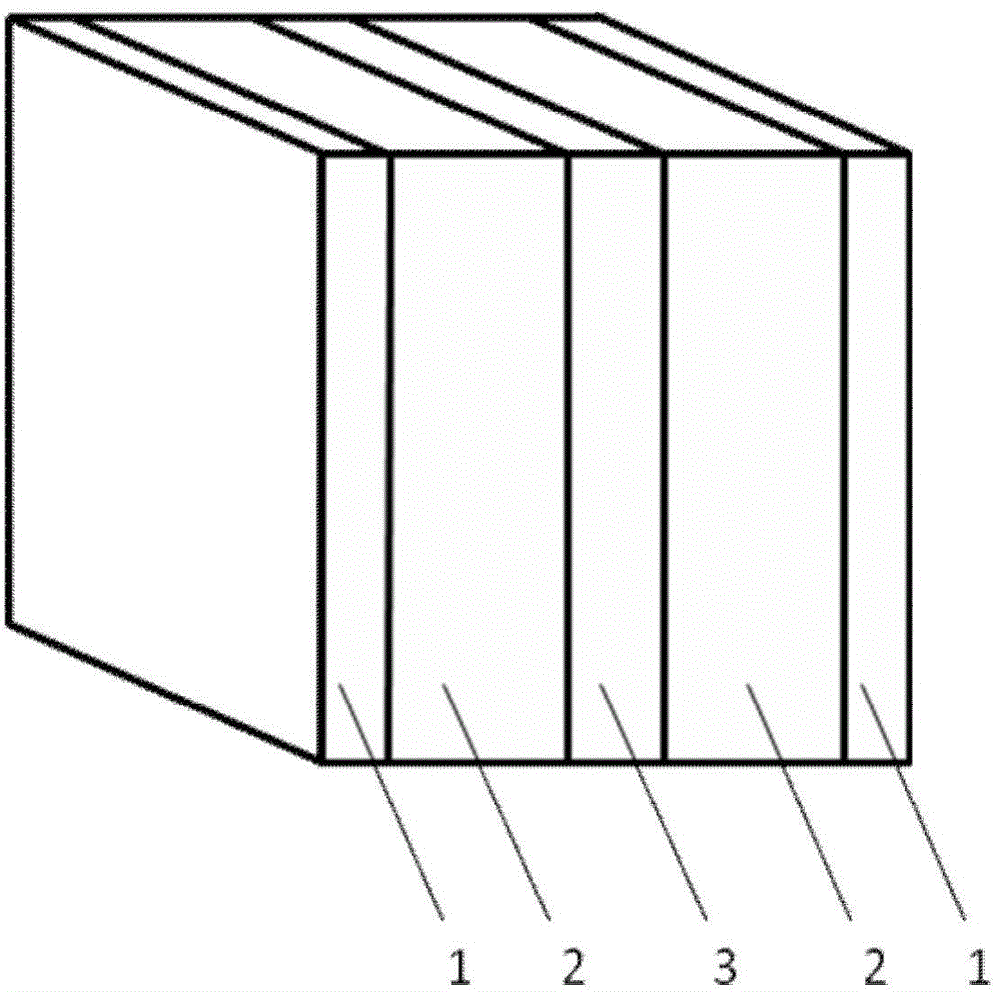

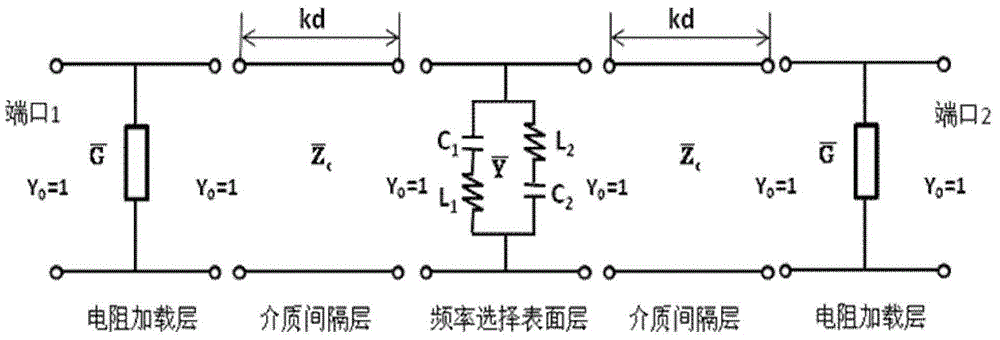

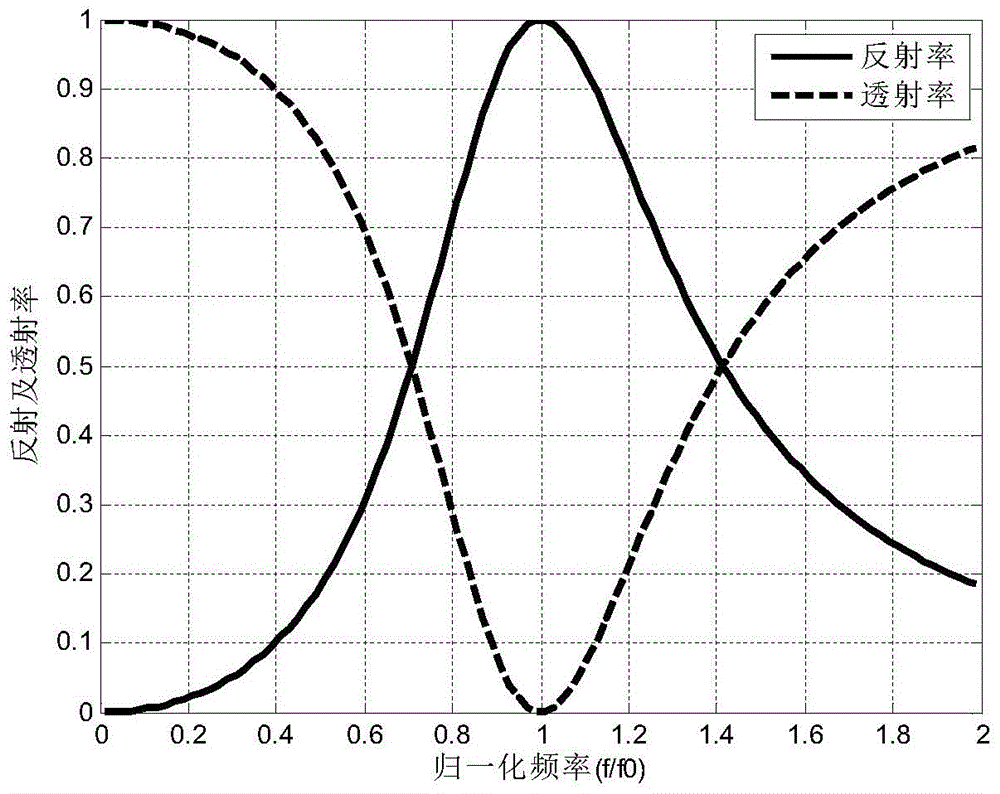

[0025] refer to figure 1 . In the embodiments described below, the impedance-type frequency selective surface is composed of a frequency selective surface layer 1 , a dielectric spacer layer 2 , and a resistive loading layer 3 . Wherein, the dielectric spacer layer 2 is made of dielectric materials such as foam, glass fiber reinforced plastic, and polytetrafluoroethylene with low loss. The frequency selective surface layer 1 composed of a single layer or multiple periodic metal patterns is attached to the dielectric spacer layer 2, and the outermost frequency selective surface layer 1 is composed of its periodic metal patterns to realize the capacitive and inductive loading of the incident electromagnetic wave , to achieve the purpose of designing the transmission characteristics from the frequency. The dielectric spacer layer 2 located on the inner surface of the frequency selective surface layer 1 may also include a certain support material or structure; the resistance loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com