Cornus officinalis total saponins obtained by response surface method optimized ultrasonic-microwave synergetic extraction and method for extracting total saponins from cornus officinalis

A response surface method, the technology of Cornus officinalis, applied in the direction of pharmaceutical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems that cannot meet the extraction requirements of Cornus officinalis, can not be fully utilized, and the extraction is not thorough, etc., to achieve the regression equation High precision, shortened extraction time, and high raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] The method for optimizing the ultrasonic-microwave synergistic extraction of total saponins from Cornus officinalis by response surface methodology of the present invention comprises the following steps:

[0039] (1) Material processing: Soak the fresh and ripe fruit of Cornus officinalis in boiling water for several minutes, rinse and cool it under running water, and remove the core; dry and pulverize the remaining pulp, and pass through a 40-mesh sieve to obtain medicinal material powder of Cornus officinalis;

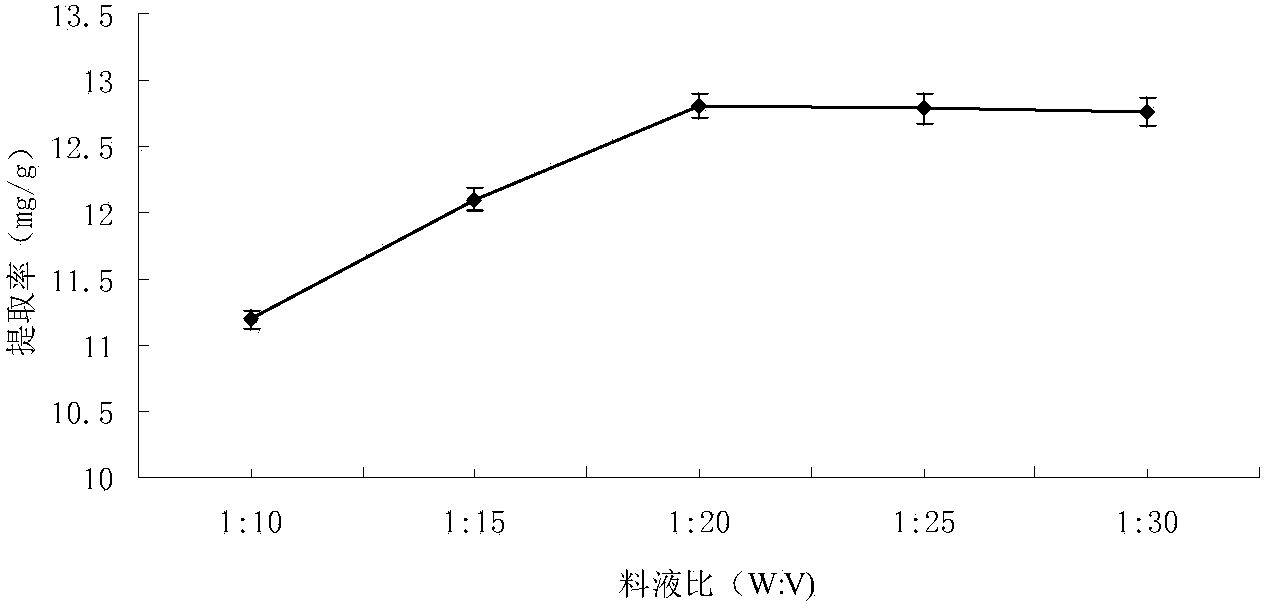

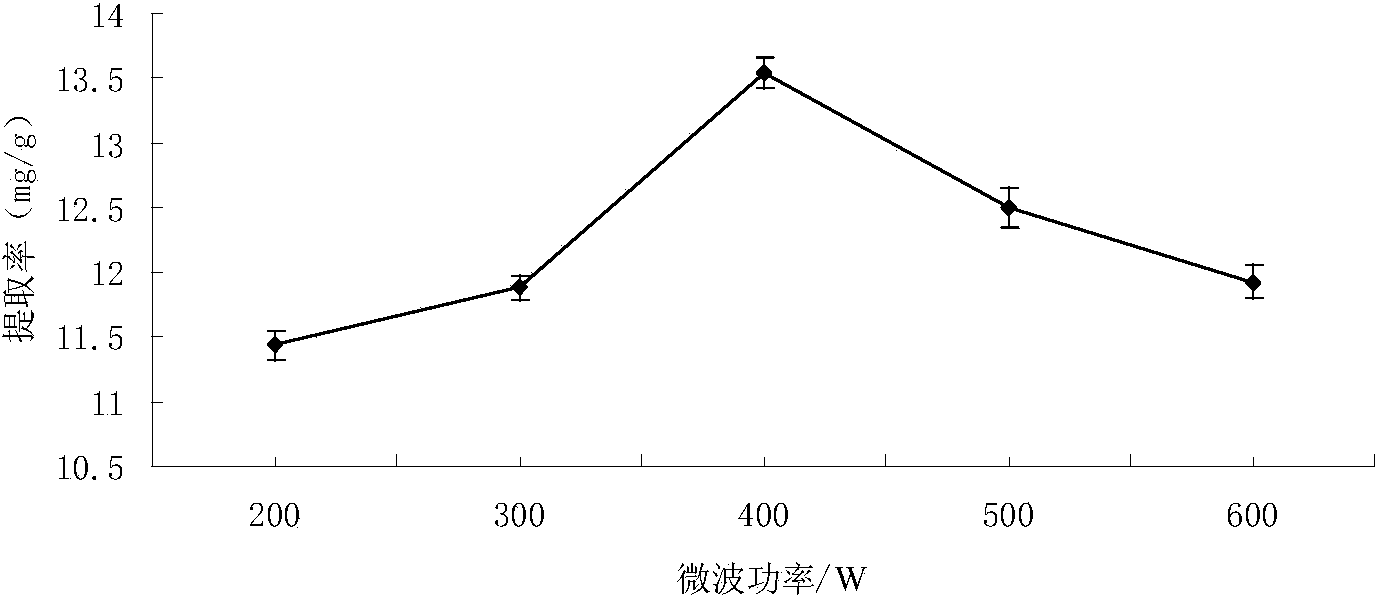

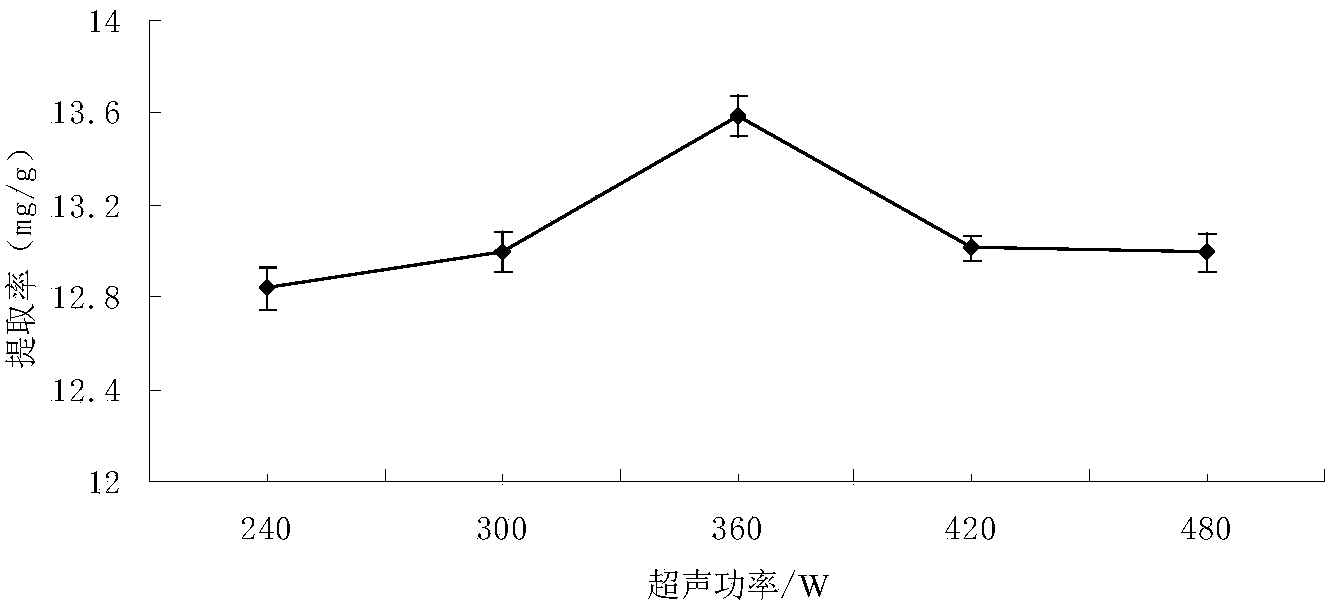

[0040] (2) Ultrasonic-microwave synergistic extraction: Weigh a certain amount of cornus officinalis medicinal material powder, put it in a reaction vessel, add an ethanol solution with a volume fraction of 70% according to the ratio of solid to liquid ratio of 1:21 and seal it, and connect the condensing device , extracted at a temperature of 70°C, a microwave power of 417W, and an ultrasonic power of 369W for 5 minutes to obtain an extract; Redissolve to obt...

example 2

[0044] The method for optimizing the ultrasonic-microwave synergistic extraction of total saponins from Cornus officinalis by response surface methodology of the present invention comprises the following steps:

[0045] (1) Material processing: Soak the fresh and ripe fruit of Cornus officinalis in boiling water for several minutes, rinse and cool it under running water, and remove the core; dry and pulverize the remaining pulp, and pass through a 40-mesh sieve to obtain medicinal material powder of Cornus officinalis;

[0046](2) Ultrasonic-microwave collaborative extraction: Weigh a certain amount of cornus officinalis medicinal material powder, put it in a reaction container, add an ethanol solution with a volume fraction of 70% according to the ratio of solid to liquid 1:10 and seal it, and connect the condensing device , at a temperature of 70°C, a microwave power of 600W, and an ultrasonic power of 500W for 6 minutes to obtain an extract; Redissolve to obtain total sapon...

example 3

[0050] The method for optimizing the ultrasonic-microwave synergistic extraction of total saponins from Cornus officinalis by response surface methodology of the present invention comprises the following steps:

[0051] (1) Material processing: Soak the fresh and ripe fruit of Cornus officinalis in boiling water for several minutes, rinse and cool it under running water, and remove the core; dry and pulverize the remaining pulp, and pass through a 40-mesh sieve to obtain medicinal material powder of Cornus officinalis;

[0052] (2) Ultrasonic-microwave synergistic extraction: Weigh a certain amount of cornus officinalis medicinal material powder, place it in a reaction container, add an ethanol solution with a volume fraction of 70% according to the ratio of solid to liquid ratio of 1:15 and seal it, and connect the condensing device , extracted at a temperature of 70°C, a microwave power of 200W, and an ultrasonic power of 420W for 9 minutes to obtain an extract; Redissolve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com