Modified asphalt oil coating pool with flue gas purifying processing system

A processing system and a technology for modified asphalt, applied in coatings, chemical instruments and methods, and devices for coating liquids on surfaces, etc., can solve the problems of high smoke density, poor ventilation effect, and affecting the health of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

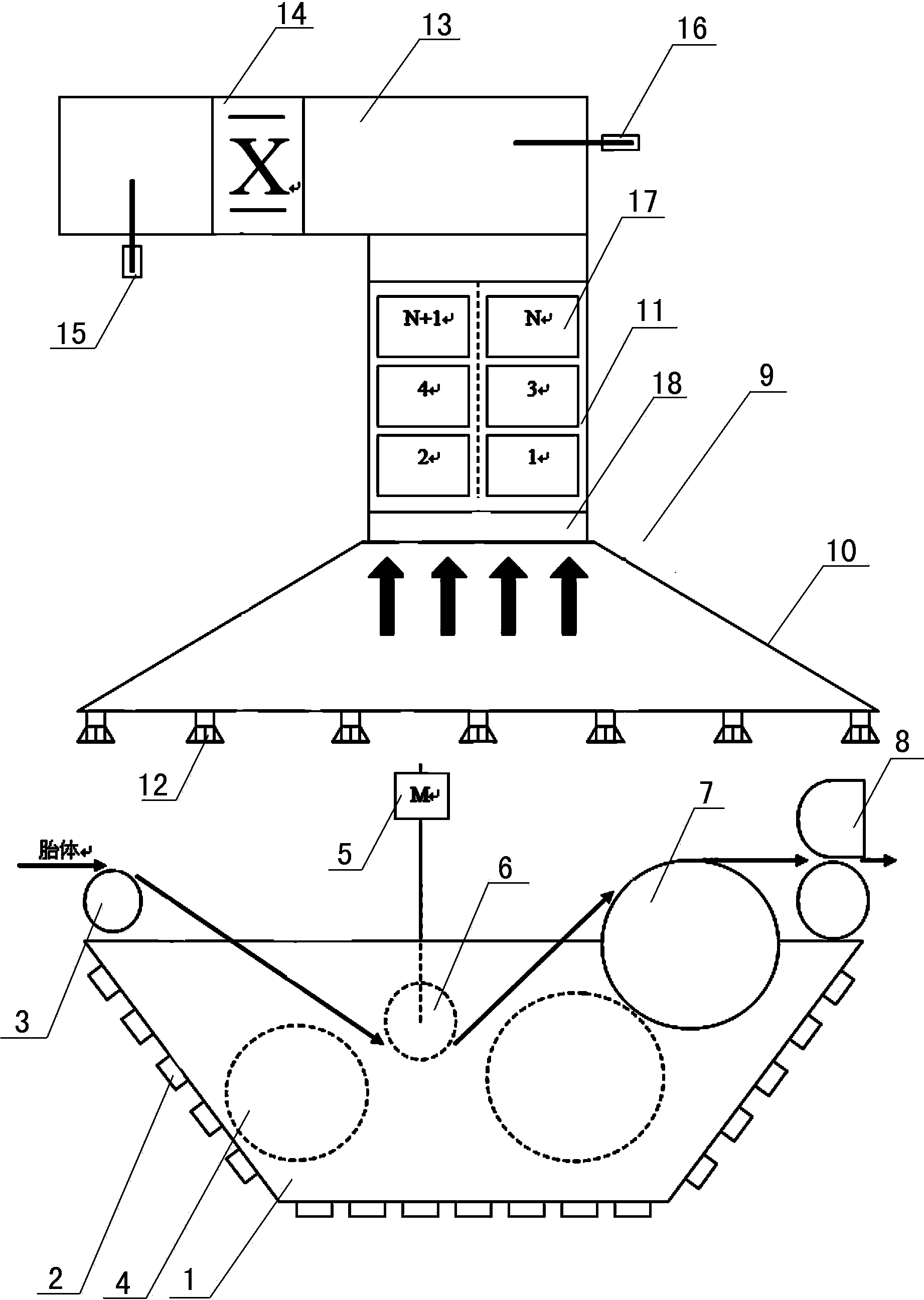

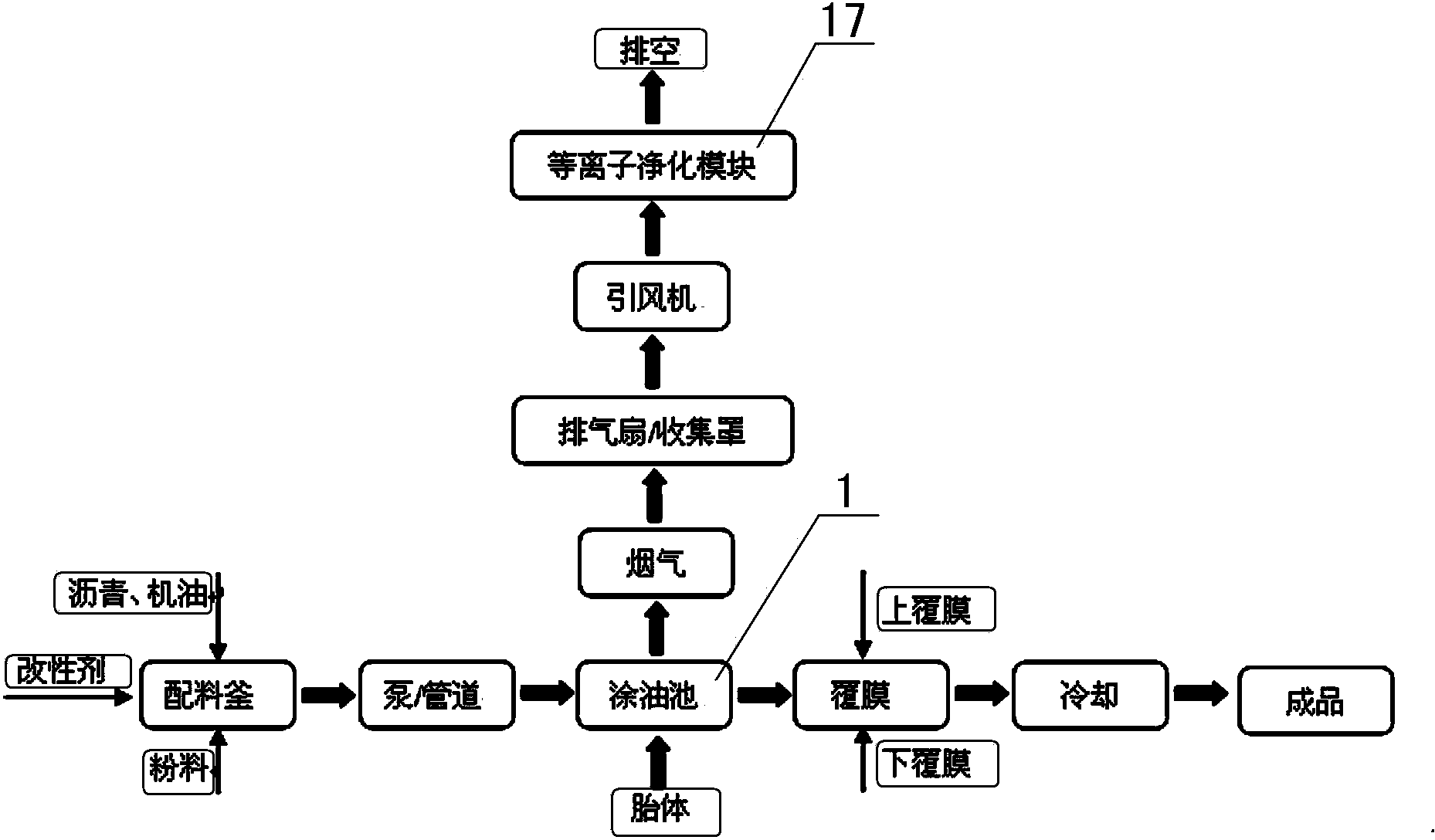

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] The reference numerals in each accompanying drawing represent as follows:

[0016] 1. Pool body;

[0017] 2. Heat conduction oil heating coil;

[0018] 3. Transition roller;

[0019] 4. Cooling roll;

[0020] 5. Settling roller motor;

[0021] 6. Drive the settling roller;

[0022] 7. Belt roller;

[0023] 8. Thickness control roller;

[0024] 9. Plasma purification tower;

[0025] 10. Gas collecting hood;

[0026] 11. Plasma module;

[0027] 12. Turbo fan;

[0028] 13. Pipeline;

[0029] 14. Tube induced draft fan;

[0030] 15. Air volume transmitter;

[0031] 16. TVOC detector;

[0032] 17. Plasma module;

[0033] 18. Cleaning ball;

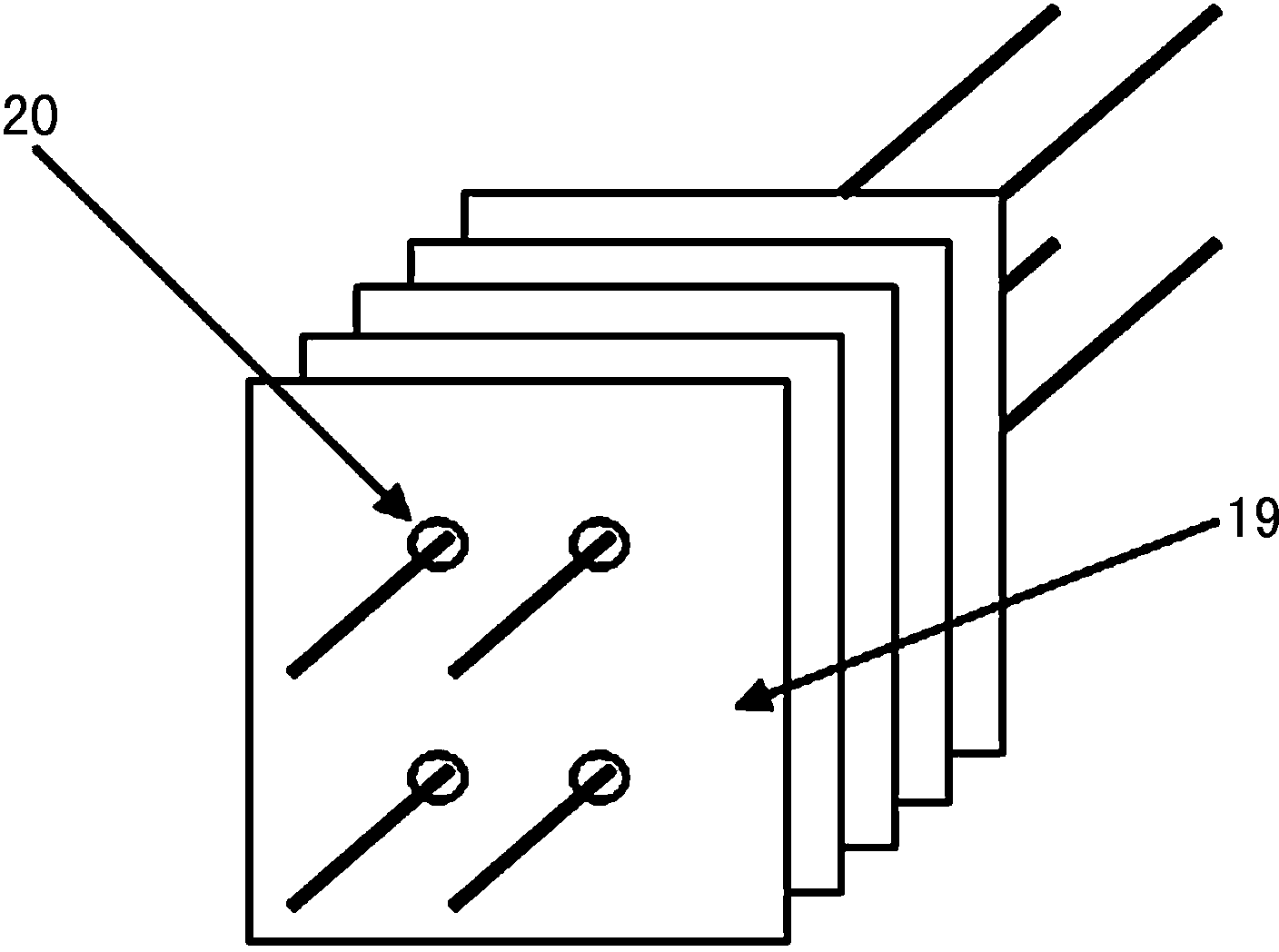

[0034] 19. Electrode plate;

[0035] 20. Electrode porcelain bottle.

[0036] A modified asphalt oiled pool with a flue gas purification treatment system according to the present invention includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com