Sample Preparer With Rotary Gripper

A technology of rotating clamps and holders, which can be used in the direction of chucks, instruments, household appliances, etc., and can solve problems such as inaccurate measurement and balance shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

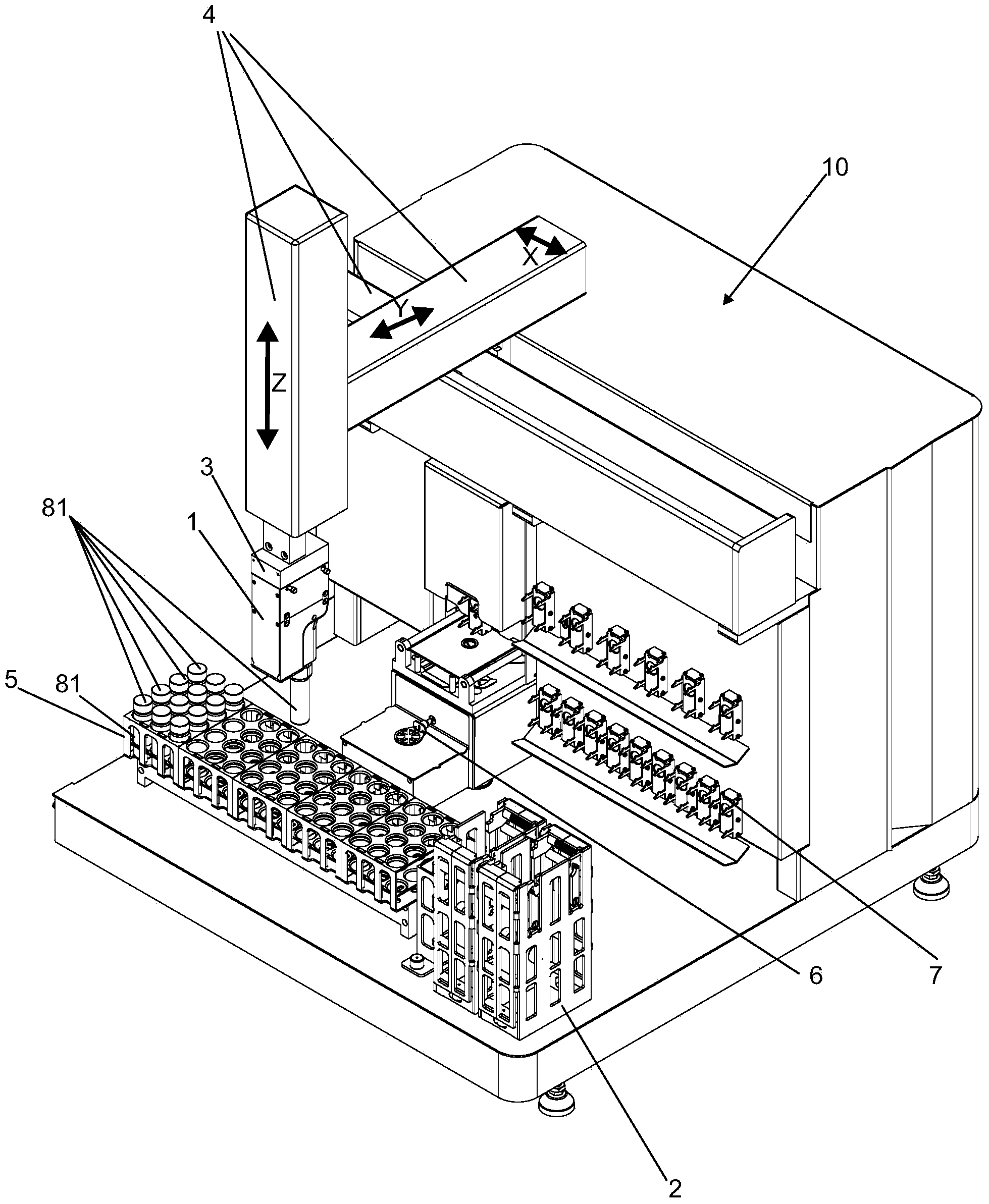

[0032] figure 1 A sample preparation system 10 is shown in which a rotatable holder 1 according to the invention is used for the preparation of a sample. The sample preparation system 10 comprises a tool substrate station 2 where various tools, such as a rotatable holder 1 or a holder for a powder dispensing head, are temporarily parked. The sample rack 5 holds a plurality of containers 81 . In the storage rack 7 for dosing heads, different materials contained in a single dispensing head can be kept ready for use. The container 81 can be placed on the load receiver 6 when preparing the sample. The movement module 4 allows the tool holder 3 to be moved in the x-direction, y-direction and z-direction.

[0033] To start the preparation of the sample, the tool holder 3 is moved by means of the movement module 4 to the tool substrate station 2 where the tool holder 3 receives the rotatable holder 1 . The closed empty container 81 is removed from the sample holder 5 by means of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com