Fly ash activator

A fly ash and activator technology, which is applied in the field of fly ash activators, can solve the problems of insignificant economic benefits of activators, damage to the durability of concrete, and affect the promotion of activators, so as to achieve considerable economic benefits, improve economic benefits and Social benefits, the effect of saving cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Fly ash activator, prepared by homogenizing and stirring the following raw materials in weight percentage: alunite 10-30, sodium sulfate 10-20, calcium chloride 10-20, sodium hydroxide 10-20, fly ash Or the remaining amount of stone powder.

Embodiment 2

[0014] Fly ash activator, prepared by homogenizing and stirring the following raw materials in weight percentage: alunite 10-20, sodium sulfate 10-15, calcium chloride 10-15, sodium hydroxide 10-15, fly ash Or the remaining amount of stone powder.

Embodiment 3

[0016] Fly ash activator, prepared by homogenizing and stirring the following raw materials in weight percentage: alunite 20-30, sodium sulfate 15-20, calcium chloride 15-20, sodium hydroxide 15-20, fly ash Or the remaining amount of stone powder.

[0017] The preparation process of the stimulant is: accurately weighing the above-mentioned components of raw materials, using a mixer with mixing and stirring functions to homogenize and stir.

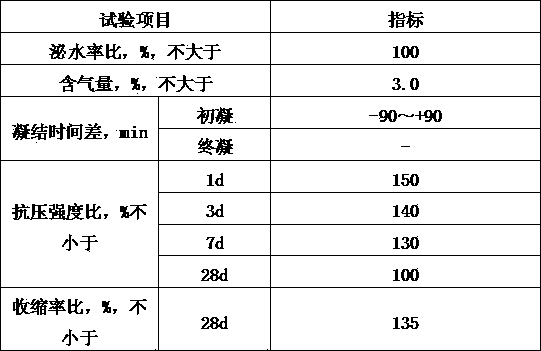

[0018] The performance index of this stimulant is in accordance with Table 1.

[0019]

[0020] This activator is used in fly ash concrete. The measured results of its mechanical properties (compressive strength ratio) are shown in Table 2 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com