High-strength high-toughness transparent polylactic acid composition and preparation method thereof

A polylactic acid and high toughness technology is applied in the field of high-strength and high-toughness transparent polylactic acid composition and its preparation, and achieves the effects of easy industrialization, good toughness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

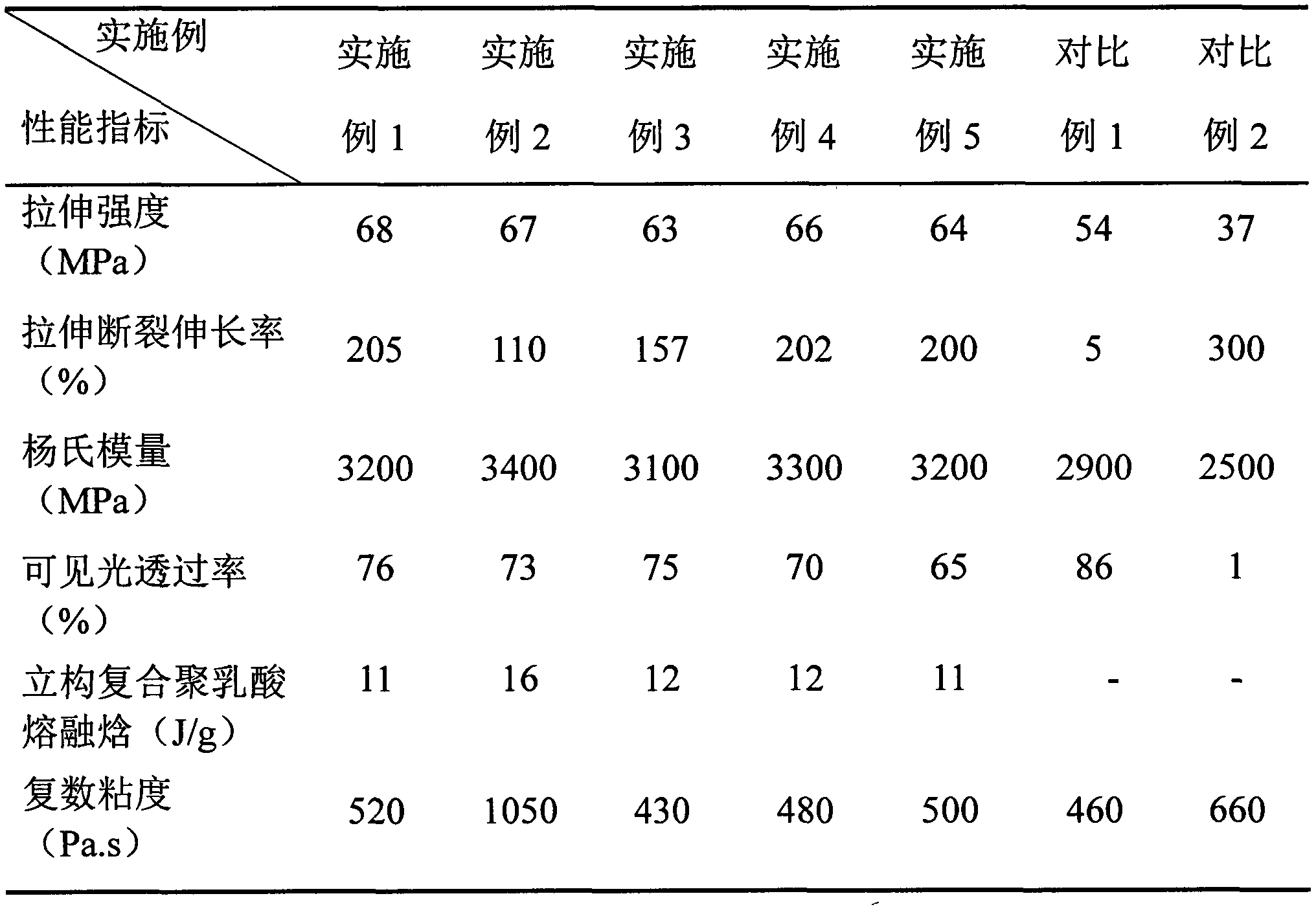

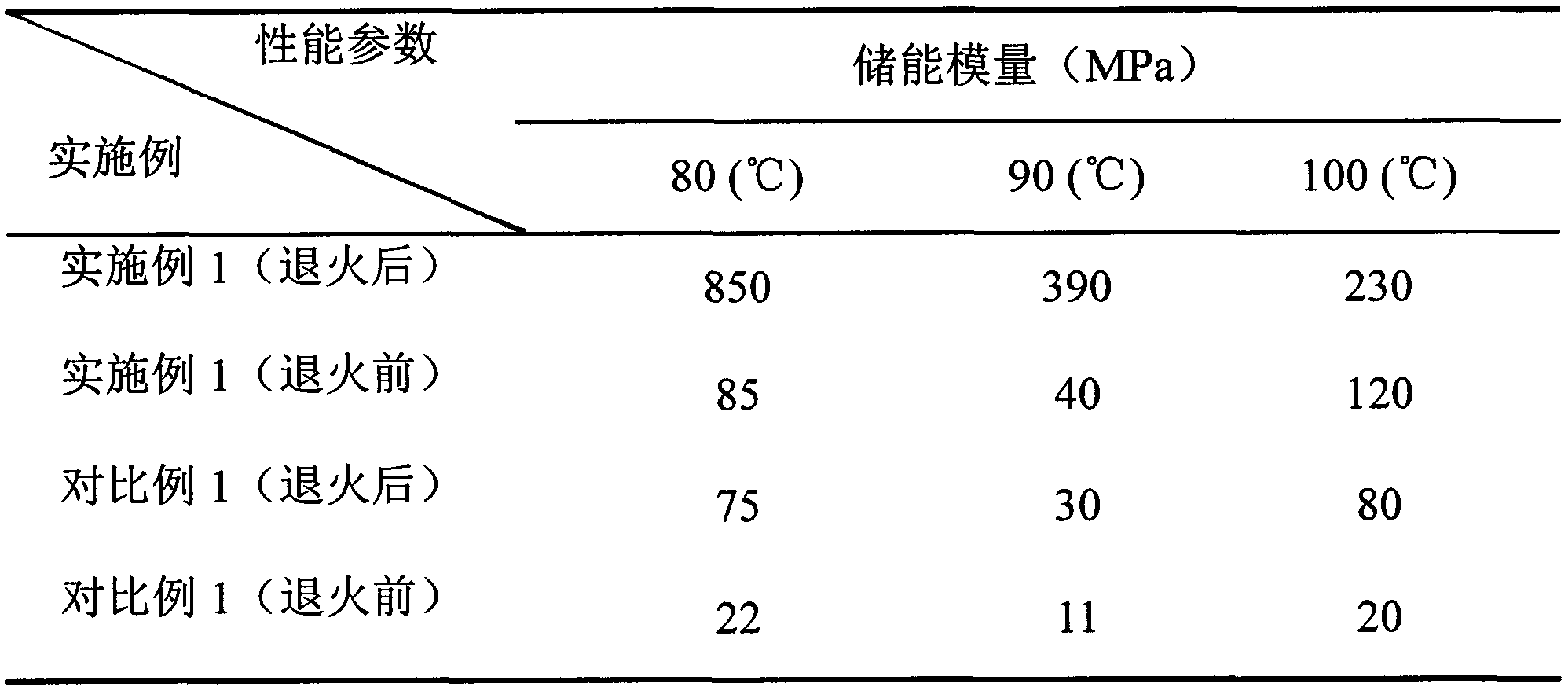

Embodiment 1

[0036] Firstly, the left-handed polylactic acid and the right-handed polylactic acid were vacuum-dried at 80°C for 8 hours for later use, and then 45g of left-handed polylactic acid, 5g of right-handed polylactic acid, 0.05g of antioxidant (1010) and 0.5g of compatibilizer (Bioadimide500XT) Pre-mixed evenly, and then the pre-mixture was melt-blended by an internal mixer at 200° C. for 5 minutes (rotor speed was 30 rpm), to obtain a high-strength and high-toughness transparent polylactic acid composition. The obtained polylactic acid composition is hot-pressed by a flat vulcanizer to obtain a 1 mm thick plastic sheet, and is cut into a standard sample according to relevant standards for mechanical performance testing, optical performance testing and thermal performance testing. The test results are listed in Table 1. In addition, the sheet was annealed at 100° C. for 3 minutes, and then the storage modulus of the polylactic acid composition sheet before and after heat treatment...

Embodiment 2

[0038] Firstly, the left-handed polylactic acid and the right-handed polylactic acid were vacuum-dried at 80°C for 8 hours for later use, and then 40 g of the left-handed polylactic acid, 10 g of the right-handed polylactic acid, 0.1 g of antioxidant (1010), and 0.02 g of antioxidant (168) and compatibilizer (Bioadimide500XT) 0.5g pre-mixed evenly, and then the pre-mixture was melt-blended by internal mixer at 200°C for 6 minutes (rotor speed is 40 rpm), to obtain a high-strength and high-toughness transparent polymer Lactic acid composition. The obtained polylactic acid composition is hot-pressed by a flat vulcanizer to obtain a 1 mm thick plastic sheet, and is cut into a standard sample according to relevant standards for mechanical performance testing, optical performance testing and thermal performance testing. The test results are listed in Table 1.

Embodiment 3

[0040] Firstly, the left-handed polylactic acid and the right-handed polylactic acid were vacuum-dried at 80°C for 8 hours for later use, and then the left-handed polylactic acid 45g, the right-handed polylactic acid 5g, the antioxidant (168) 0.05g and the compatibilizer (Bioadimide500XT) 0.5g Pre-mixed evenly, and then the pre-mixture was melt-blended by an internal mixer at 210° C. for 5 minutes (rotor speed was 30 rpm), to obtain a high-strength and high-toughness transparent polylactic acid composition. The obtained polylactic acid composition is hot-pressed by a flat vulcanizer to obtain a 1 mm thick plastic sheet, and is cut into a standard sample according to relevant standards for mechanical performance testing, optical performance testing and thermal performance testing. The test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com