QPZ additive and laundry detergent using same

A technology of laundry detergent and auxiliaries, applied in the field of home furnishing, can solve the problems of wrinkling, difficult cleaning and instability of clothes, and achieve the effects of strong detergency, stable quality and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A kind of synthetic method of QPZ auxiliary agent is, the fatty acid of 60% by weight percentage, the acetic acid of 10% by weight percentage, the triethanolamine of 16% by weight percentage, the protease of 10% by weight percentage, the citric acid of 4% by weight percentage are carried out Mix and stir for 1 hour, age for 1 hour, and then condense at a temperature of 35°C and a pressure of 80Kpa to form a polymer modified condensate.

Embodiment 2

[0015] A kind of synthetic method of QPZ auxiliary agent is, the fatty acid of 68% by weight percentage, the acetic acid of 8% by weight percentage, the triethanolamine of 12% by weight percentage, the protease of 2% by weight percentage, the citric acid of 10% by weight percentage are carried out Mixing and stirring for 1 hour, aging for 1 hour, and then concentrating at a temperature of 40° C. and a pressure of 80 Kpa to form a polymer modified condensate.

Embodiment 3

[0017] A kind of synthetic method of QPZ auxiliary agent is, the fatty acid of 70% by weight percentage, the acetic acid of 5% by weight percentage, the triethanolamine of 5% by weight percentage, the protease of 8% by weight percentage, the citric acid of 12% by weight percentage are carried out Mixing and stirring for 1 hour, aging for 1 hour, and then concentrating at a temperature of 45° C. and a pressure of 80 Kpa to form a polymer modified condensate.

[0018] A kind of laundry detergent, is made up of the composition of following percentage by weight:

[0019] 4% said QPZ additive; 0.3% liquid caustic soda; 2% sulfonic acid with a concentration of 96%; 10% AES with a concentration of 70%; 4% AEO-9; 4% AEO-7; 1% sodium chloride; 0.1% brightener; 0.3% triethanolamine; 0.2% citric acid; 1% liquid enzyme; 73.1% deionized water.

[0020] The laundry detergent made has been tested and can achieve the following effects:

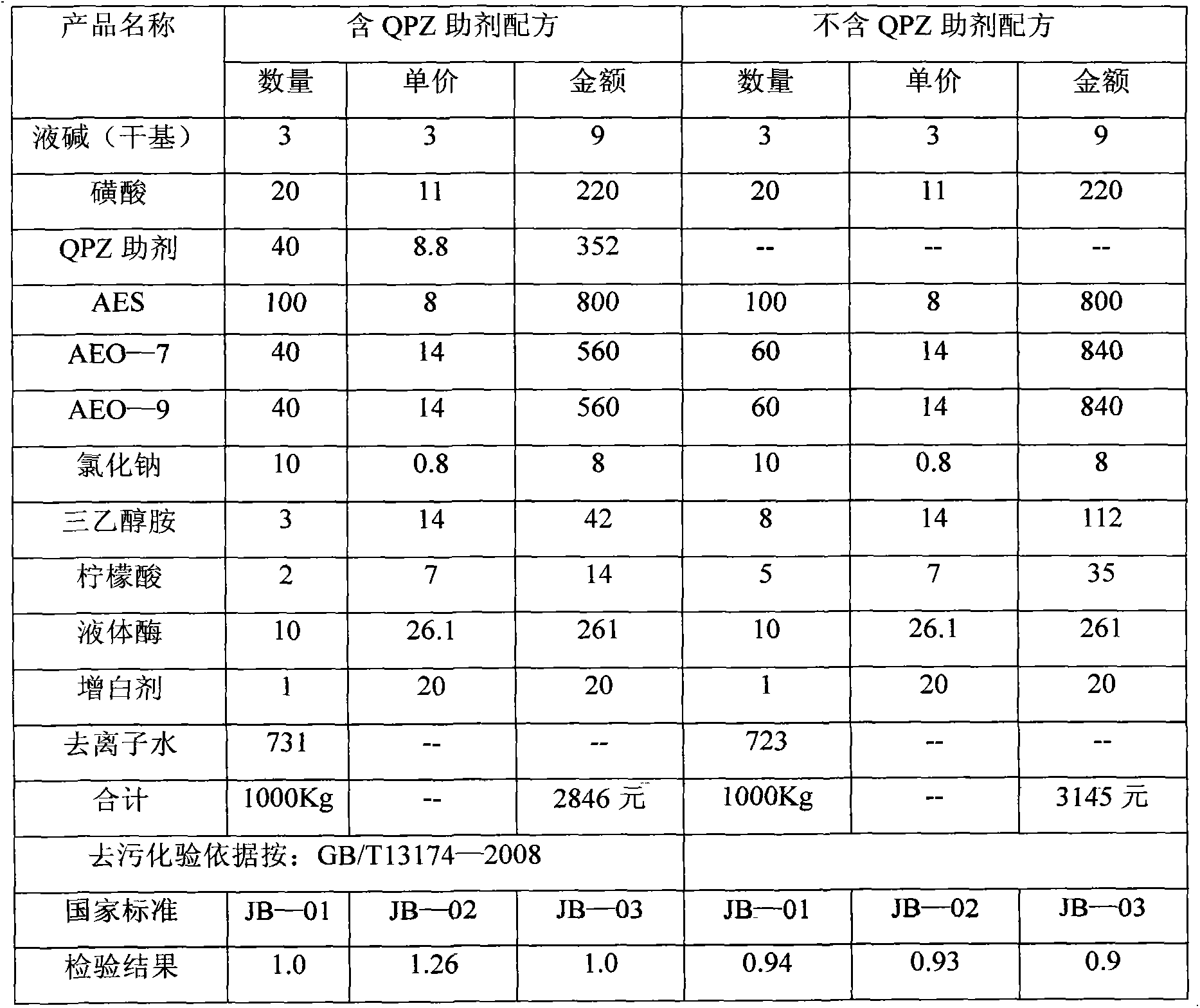

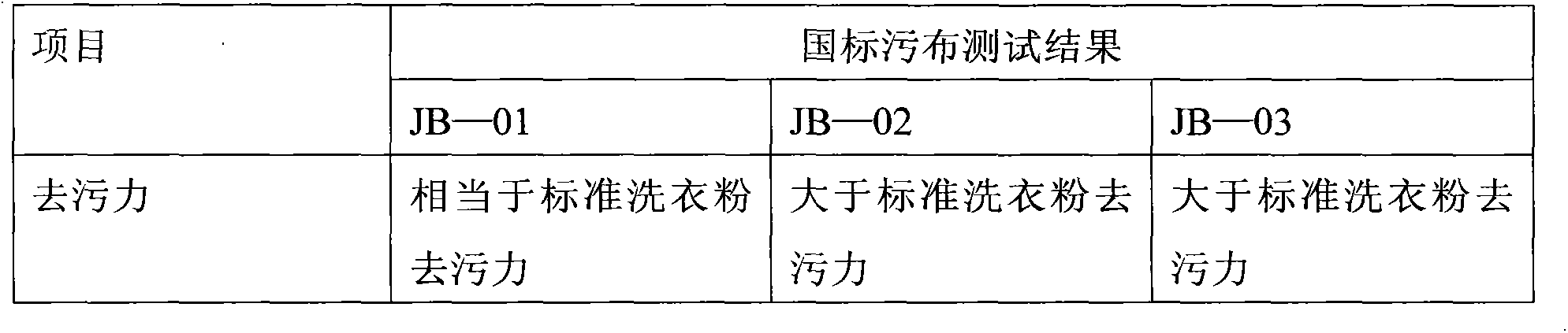

[0021] Table 1: Comparison table of cost-effectivenes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com