3d‑ic with complex microchannel fluid cooling between layers

A 3D-IC and micro-channel technology, applied in the direction of electrical solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of reduced wiring resources and reduced chip reliability, to improve uniformity and reduce voltage drop, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

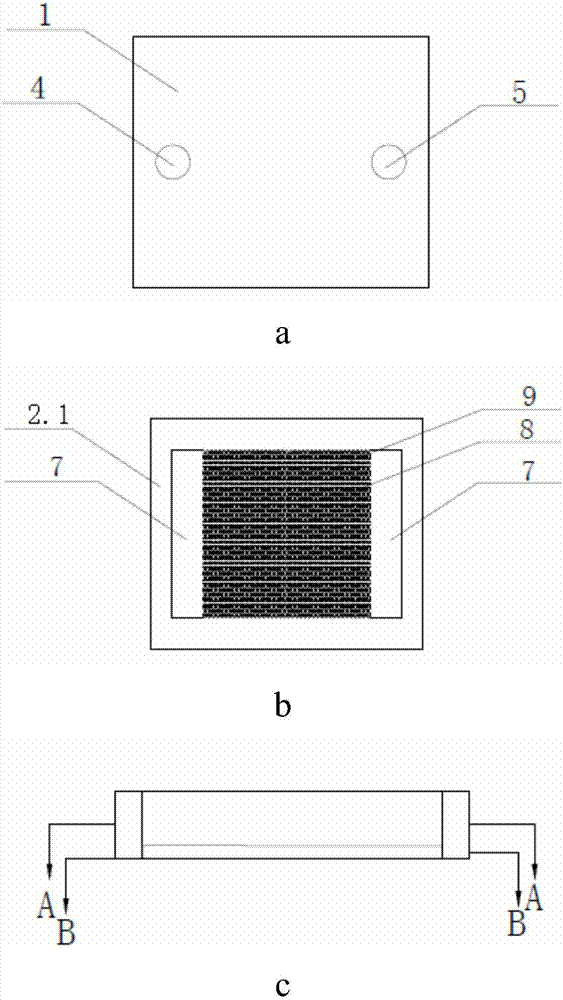

[0051] The present invention will be further described below in conjunction with the accompanying drawings and the application of interlayer fluid cooling 3D-IC with dislocated fan-shaped concave microchannels:

[0052] 3D-IC with low power consumption, short transmission distance, fast transmission rate, low delay, low noise, and high frequency has become the focus of attention. However, due to the stacking of integrated circuits, the power consumption density of the chip doubles in the same area, resulting in a doubled increase in the heat generated by the chip, and the insulating dielectric layer with low thermal conductivity between the layers connecting the circuit, the heat dissipation of the 3D-IC becomes key issues that limit its development. Interlayer fluid cooling of 3D-IC with complex microchannels has become its effective heat dissipation technology. Interlayer fluid cooling 3D-IC with misplaced fan-shaped concave microchannels consists of a sealing sheet (1), a ...

Embodiment 2

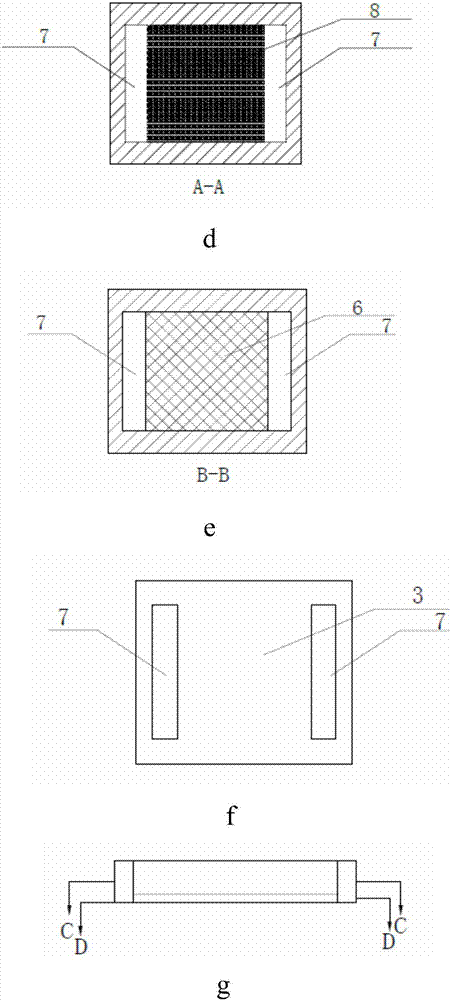

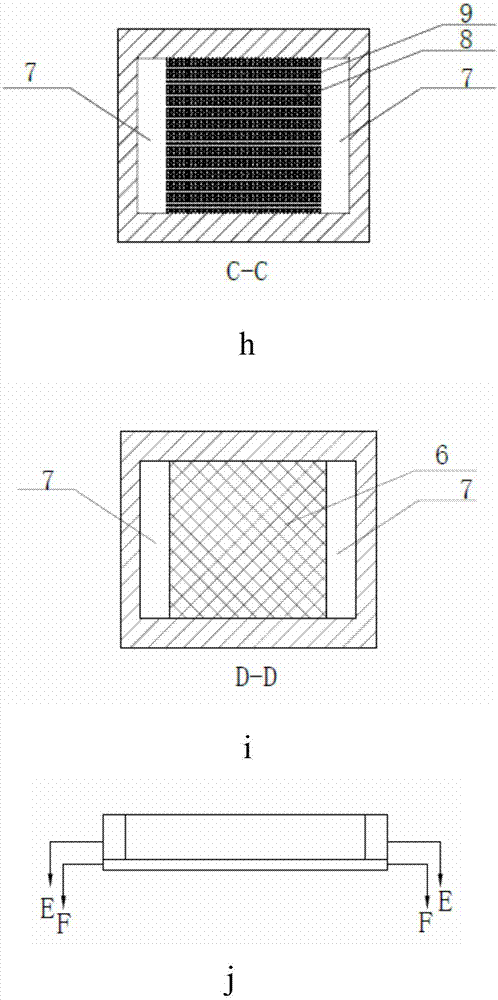

[0062] The present invention will be further described below in conjunction with the accompanying drawings and the application of the 3D-IC with misplaced triangular recessed microchannel liquid interlayer cooling:

[0063]3D-IC with low power consumption, short transmission distance, fast transmission rate, low delay, low noise, and high frequency has become the focus of attention. However, due to the stacking of integrated circuits, the power consumption density of the chip doubles in the same area, resulting in a doubled increase in the heat generated by the chip, and the insulating dielectric layer with low thermal conductivity between the layers connecting the circuit, the heat dissipation of the 3D-IC becomes key issues that limit its development. Interlayer fluid cooling of 3D-IC with complex microchannels has become its effective heat dissipation technology. The interlayer fluid cooling 3D-IC with dislocation triangular cavity microchannel is composed of sealing sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com