Polyoxometallate-based composite film

A polyoxometalate and composite thin film technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of difficult to achieve green environmental protection, high price, etc., achieve good photoelectric response, easy operation, and uniform film formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

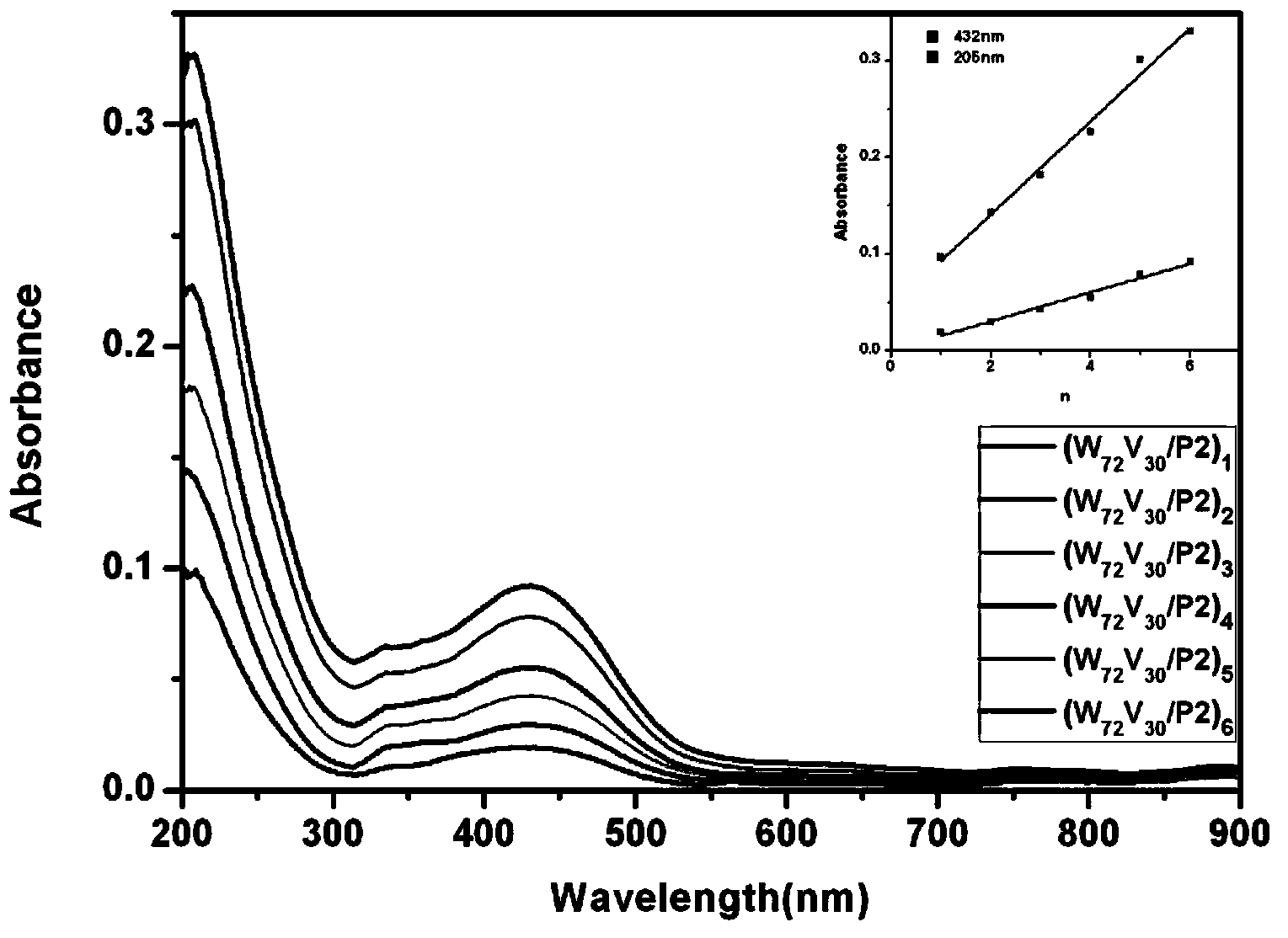

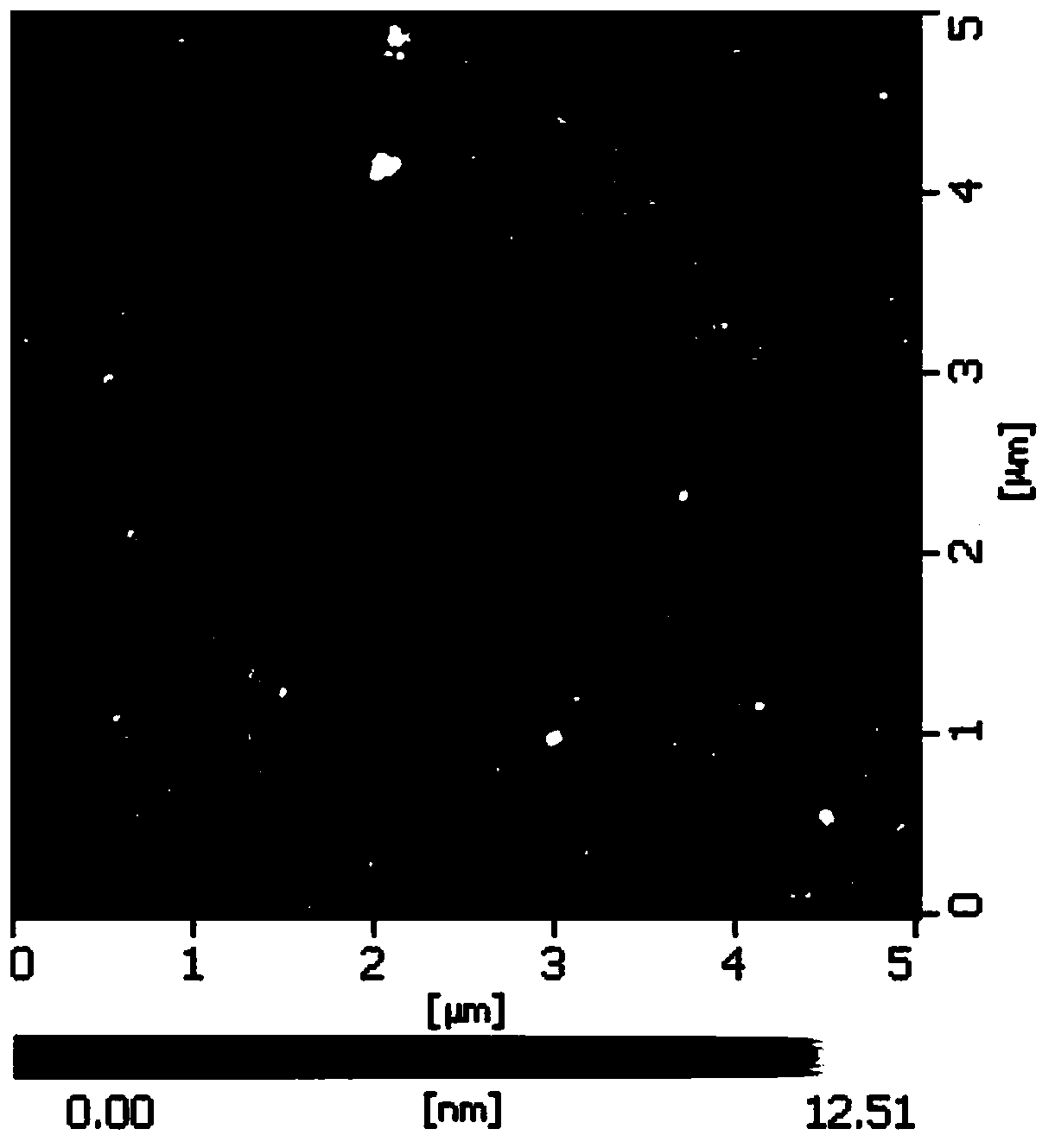

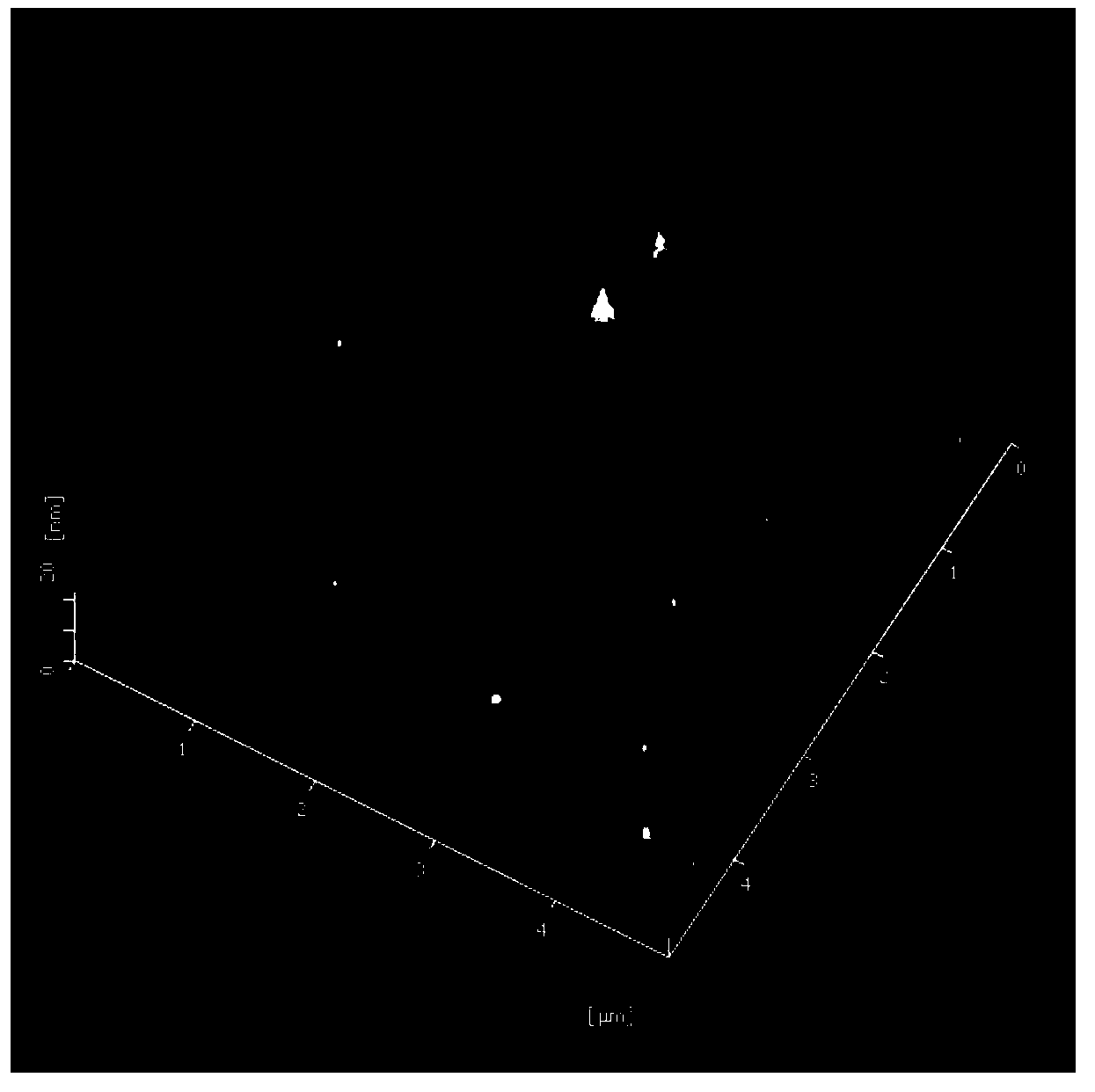

[0034] will {W 72 V 30} Dissolve in water to prepare a 0.5mmol / L aqueous solution, adjust the pH of the solution to 2 with sulfuric acid, dissolve the water-soluble PPV derivative P2 in water, and prepare a 0.3mg / mL aqueous solution. Soak the ITO substrate in the piranha solution for 20 minutes, take it out, rinse it with deionized water, blow it dry with nitrogen, then soak it in 0.25mg / mL PEI solution for 20 minutes, take it out, rinse it with deionized water, blow it dry with nitrogen Dry, get a pre-treated substrate.

[0035] Soak the treated substrate in {W 72 V 30} in the aqueous solution for 20 minutes, take it out, rinse it with deionized water, dry it with nitrogen gas, then soak it in the P2 aqueous solution for 20 minutes, take it out, rinse it with deionized water, and blow it dry with nitrogen gas. In this way, the substrates are adsorbed on {W 72 V 30} and P2, repeated 5 times to prepare polyoxometalate-based composite films.

[0036] With the composite th...

Embodiment 2

[0038] will {W 72 V 30} Dissolve in water to prepare a 0.5mmol / L aqueous solution, adjust the pH of the solution to 2 with sulfuric acid, dissolve the water-soluble PPV derivative P2 in water, and prepare a 0.3mg / mL aqueous solution. Soak the ITO substrate in the piranha solution for 20 minutes, take it out, rinse it with deionized water, blow it dry with nitrogen, then soak it in 0.25mg / mL PEI solution for 20 minutes, take it out, rinse it with deionized water, blow it dry with nitrogen Dry, get a pre-treated substrate.

[0039] Soak the treated substrate in {W 72 V 30} in the aqueous solution for 20 minutes, take it out, rinse it with deionized water, dry it with nitrogen gas, then soak it in the P2 aqueous solution for 20 minutes, take it out, rinse it with deionized water, and blow it dry with nitrogen gas. In this way, the substrates are adsorbed on {W 72 V 30} and P2 were repeated 10 times to prepare polyoxometalate-based composite films.

[0040] With the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com