Mining Electric Dump Truck Brushless Synchronous Generator and Mine Electric Dump Truck

A technology for synchronous generators and dump trucks, which is applied in synchronous generators, engine-driven traction, electric vehicles, etc., to achieve the effects of reducing maintenance costs, light weight, and improving vehicle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

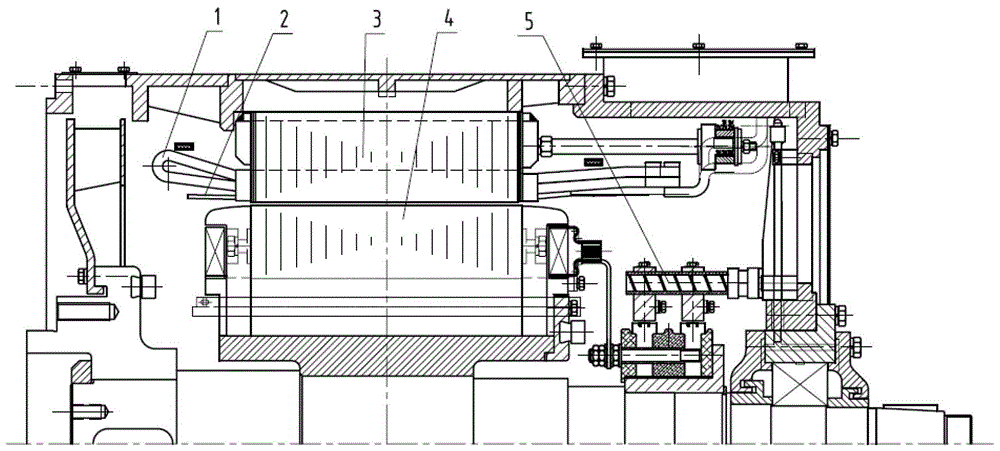

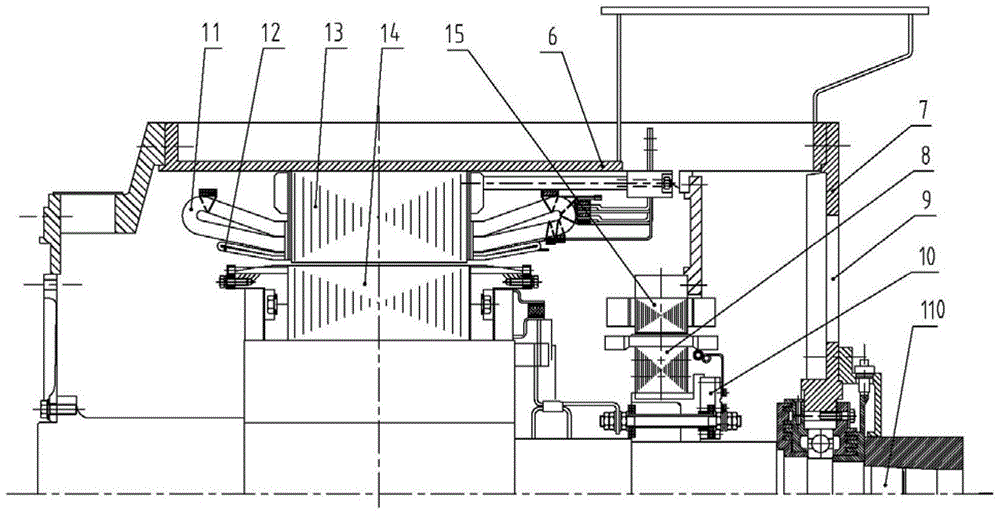

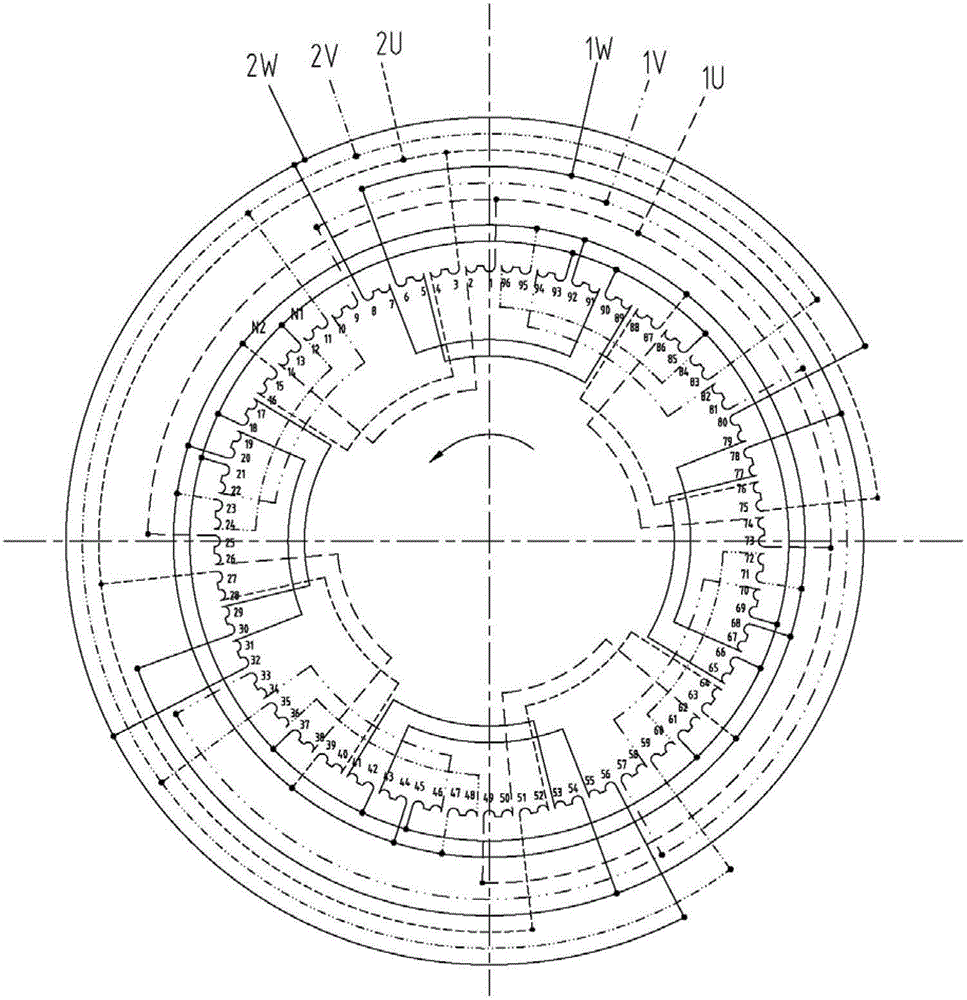

[0018] figure 2 A schematic structural diagram of a brushless synchronous generator provided by an embodiment of the present invention; image 3 for figure 2 The winding layout diagram of the stator winding of the medium generator; figure 2 , image 3 As shown, the mine electric dump truck brushless synchronous generator provided by the present invention at least includes a base 6, a generator rotor, a generator stator, an exciter stator 15, an exciter rotor 8, and an exciter rotor 8 The connected rotary rectifier 10 and the end cover 7 used to support the generator rotor in cooperation with the base 6, the generator stator includes a stator core 13 and a stator winding wound on the stator core 13, the stator winding includes the main generator winding 11 and the auxiliary generator Winding 12; the generator rotor includes a rotating shaft 110, a rotor core 14, and a magnetic pole winding wound on the rotor core 14; the rotor core 14, the exciter rotor 8 and the rotary r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com