High-temperature-resistant modified double-horse-based electromagnetic composite material and preparation method thereof

A composite material and high temperature resistant technology, which is applied in the field of high temperature resistant modified bima-based electromagnetic composite materials and its preparation, can solve the problems of easy softening, insufficient bearing capacity, cumbersome and other problems, and achieve the effect of high temperature resistance and high magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The first aspect of the present invention provides a method for preparing a high-temperature-resistant modified double-horse resin-based electromagnetic wave-absorbing composite material. The method includes the following steps:

[0017] (1) Mix FeSiAl powder, carbonyl iron powder, acetone, and coupling agent evenly and dry to obtain FeSiAl / carbonyl iron composite powder;

[0018] (2) mixing and melting bismaleimide resin, epoxy resin and curing agent to obtain bismaleimide resin glue;

[0019] (3) Mix the FeSiAl / carbonyl iron composite iron powder prepared in step (1) with the Shuangma resin glue prepared in step (2) to obtain FeSiAl / carbonyl iron powder / Shuangma resin slurry;

[0020] (4) remove the diluent in FeSiAl / carbonyl iron powder / double horse resin slurry;

[0021] (5) The FeSiAl / carbonyl iron powder / Shuangma resin slurry from which the diluent has been removed is solidified and molded to obtain a high-temperature-resistant modified Shuangma resin-based elect...

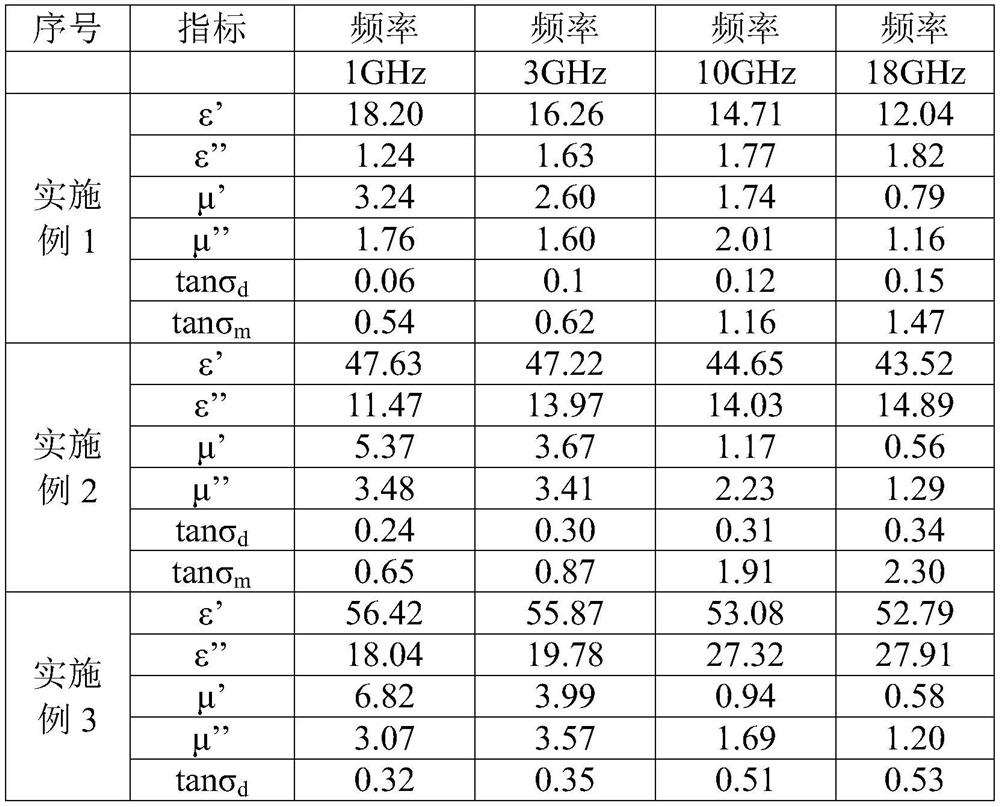

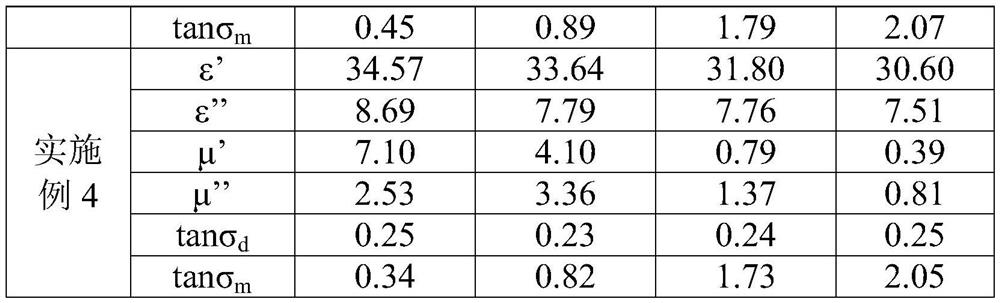

Embodiment 1

[0046] Weigh 100g 4,4'-bismaleimide diphenylmethane, 10g E51 epoxy resin (viscosity at room temperature is 1200cP), 40g 4,4'-diaminodiphenylsulfone, stir at 140°C for 1h until uniform , to obtain modified double horse resin (the proportion of hydroxyl group is 9.7%); then 80g untreated carbonyl iron powder (average particle size is 3.0 micron), 20g modified double horse resin, 0.2g KH-550 are mixed under vacuum assistance Stir for 6 hours; finally, pour the composite slurry into the mold, and mold it in an autoclave under 1 MPa pressure, 140°C / 2h, 170°C / 2h, 200°C / 3h, and finally get carbonyl iron powder / modified double horse resin composite Material.

Embodiment 2

[0048] Mix 800g steel balls (12mm(200g)+8mm(450g)+5mm(150g)) with 450g FeSiAl powder and 200g carbonyl iron powder, then add 0.1g calcium stearate and 400mL acetone together and put them in the ball mill jar , fixed speed 400r / min high-energy ball mill 16h, the average particle size obtained is 3.1 micron powder; Weigh 100g 4,4'-bismaleimide diphenylmethane, 10g E51 epoxy resin (viscosity at room temperature is 1200cP ), 40g of 4,4'-diaminodiphenylsulfone, stirred at 140°C for 1h until uniform, and obtained modified bis-horse resin (the proportion of hydroxyl group was 11.6%); then 400g of ball-milled flake FeSiAl / carbonyl iron powder , 105g modified Shuangma resin, 0.2g KH-550 were mixed and stirred for 2h under vacuum assistance; finally, the composite slurry was poured into the mold, under 1MPa pressure, 140°C / 2h, 170°C / 2h, 200°C / 3h It is molded in an autoclave to finally obtain a flaky FeSiAl / carbonyl iron powder / modified double horse resin composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com