A kind of flake ferrite electromagnetic composite material and preparation method thereof

An electromagnetic composite material, ferrite technology, applied in fibrous fillers, chemical instruments and methods, inorganic pigment processing, etc., can solve the problem of spherical ferrite materials being difficult to meet, achieve good impedance matching, avoid optimal design, The effect of excellent electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] More comprehensively, the preparation method provided by the invention may include the following preparation steps:

[0061] (1) Ball milling step: ferrite powder, steel balls, ball milling aids and volatile solvents are ball milled for 7-8 hours at a speed of 400-500r / min, and the rigid balls include steel balls with a diameter of 8mm and steel balls with a diameter of 6mm Balls, to get flake ferrite. The mass ratio of the ferrite powder, the steel ball, the ball milling aid and the volatile solvent is preferably (100-130): (350-500): (0.01-0.05): (200- 300), more preferably (115-120): (400-450): (0.02-0.03): (250-300). The mass ratio of the 8mm diameter steel ball to the 6mm diameter steel ball is preferably 5:7. The ball milling aid can be calcium stearate. The volatile solvent can be acetone.

[0062] (2) Coupling modification step: mixing the coupling modifier and the flake ferrite prepared in step (1) to obtain the flake ferrite after coupling treatment. The ...

Embodiment 1

[0072] Weigh 18g epoxy resin, 4g 501 diluent, 3g 2-ethyl-4-methylimidazole, mix and stir at room temperature for 0.5h.

[0073] Subsequently, 75 g of untreated FeSiAl powder was added, and 0.24 g of KH-550 was added, and mixed and stirred for 8 hours under vacuum assistance to obtain a mixed slurry.

[0074] Finally, the mixed slurry was poured into a mold, cured in an autoclave at 110°C under a pressure of 1.2 MPa, and a ferrite / epoxy resin composite material was finally obtained.

Embodiment 2

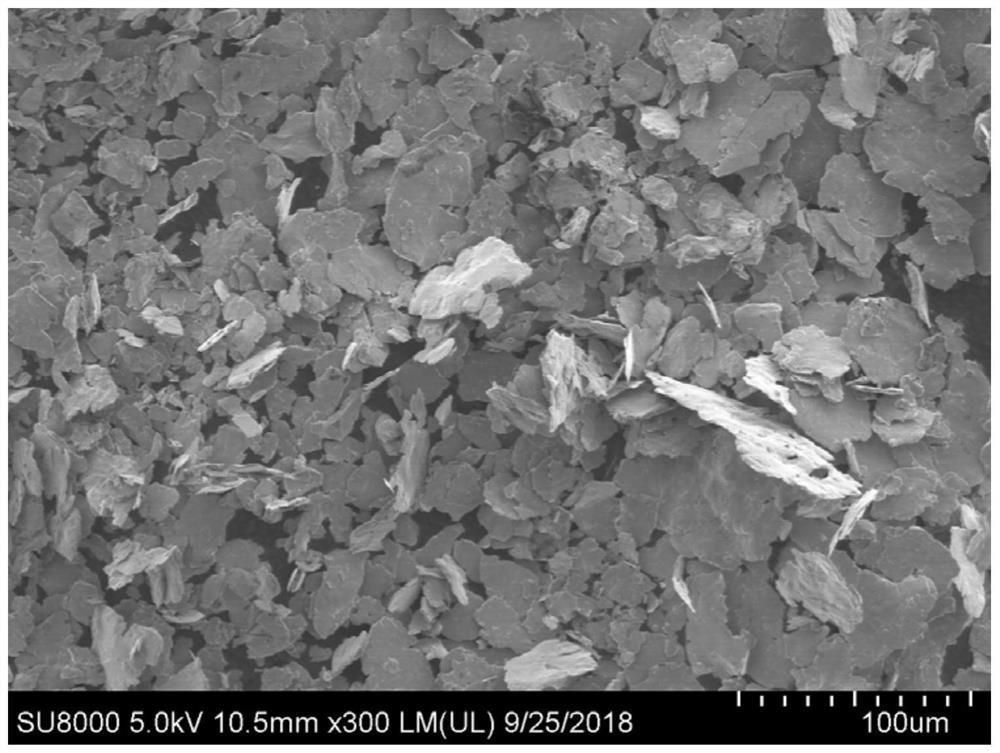

[0076] Mix 400g of steel balls (167g of 8mm diameter steel balls + 233g of 6mm diameter steel balls) with 120g of FeSiAl powder, then add 0.02g of calcium stearate and 250mL of acetone together and put them in a ball mill jar, and perform high energy ball milling at a fixed speed of 450r / min for 7.5h , to obtain sheet-shaped ferrite with an average sheet length of 30-35μm, and its microscopic topography refers to figure 1 .

[0077] Weigh 18g epoxy resin, 4g 501 diluent, 3g 2-ethyl-4-methylimidazole, mix and stir for 0.5h at room temperature, then add 75g ball-milled flake FeSiAl powder, then add 0.24gKH-550, in Mix and stir for 8 h under vacuum assistance to obtain a mixed slurry.

[0078] Finally, the composite slurry was poured into a mold, cured in an autoclave under a pressure of 1.2MPa and 110°C, and a sheet-like FeSiAl / epoxy resin composite material was finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com