Image real-time correction output method for linear array CCD imaging system based on FPGA

An imaging system and real-time correction technology, applied in image communication, electrical components, etc., can solve problems such as poor correction scheme and output image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

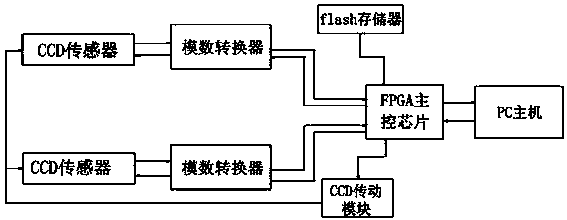

[0047] Such as figure 1 Shown, the present invention is mainly applied to the linear array CCD imaging system aspect based on FPGA, and its hardware aspect, mainly is provided with the FPGA main control chip of algorithm module (being hardware multiplier) and random access memory (being RAM) inside, The analog-to-digital converter whose output end is connected to the input end of the FPGA main control chip, the CCD transmission module connected to the output end of the FPGA main control chip, the flash memory and the PC host that are bidirectionally connected to the FPGA main control chip, and the output terminal It consists of a CCD sensor connected to the input of the analog-to-digital converter and also connected to the CCD transmission module.

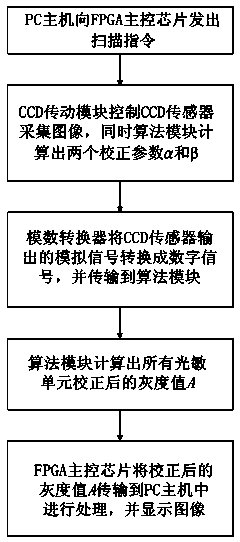

[0048] Based on the above hardware structure, such as figure 2 Shown, the realization process of the present invention is as follows:

[0049] (1) After the system is powered on, the PC host sends scanning instructions to the FP...

example 1

[0067] This example is applied in large-format scanning imaging, such as image 3 , 4 as shown, image 3 is the schematic diagram without correction, Figure 4 It is a schematic diagram after correction. From image 3 It can be seen from the figure that before the correction, the gray value of each pixel is offset from the real value, and the degree of offset is different, so the scanned picture can clearly see that there is a color generation in the distribution, and each The images scanned by each CCD sensor have obvious gaps in the stitching, and some details between pixels affect the observation due to the inconspicuous contrast, which seriously affects the interpretation of the image. After correction, the gray scale is re-stretched to the normal range, the color band is basically removed, the picture quality is significantly improved, and the attributes of the image are more truly reflected, and the details are clearer.

example 2

[0069] Such as Figure 5-9 As shown, in the PCB appearance inspection machine, the picture of the PCB circuit board collected by the CCD sensor is as follows: Figure 5 As shown, the marked 1 and 2 are two identical metal areas. Due to the uneven gray distribution of the image before correction, the gray distribution curves of the same row in areas 1 and 2 will also have large deviations. Figure 6 It is a schematic diagram of gray value distribution in line 10 of area 1 before correction, Figure 7 It is a schematic diagram of the gray value distribution of the 10th line of area 2 before correction. It can be seen that the gray value of the 10th line of area 1 before correction is distributed between 35 and 42, and the average value is 38. The gray value of the 10th line of area 2 is The gray value distribution is between 50 and 65, the average value is 57, and the difference between the two is about 9 gray values. Since the gray distribution of two metals of the same mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com