Modular humidification-dehumidification apparatus for concentrating solutions

A modular, solution technology, applied in refrigeration and liquefaction, compressors, chemical instruments and methods, etc., which can solve the problems of large footprint, multi-vapor space, and large footprint of thermal desalination devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following description, directional terms such as "top", "bottom", "upward", "downward", "vertical", "transverse", etc. are used for the purpose of providing relative reference only, and these terms are not intended to Any restriction on how any object may be placed during use or mounted in an assembly or relative to the external environment.

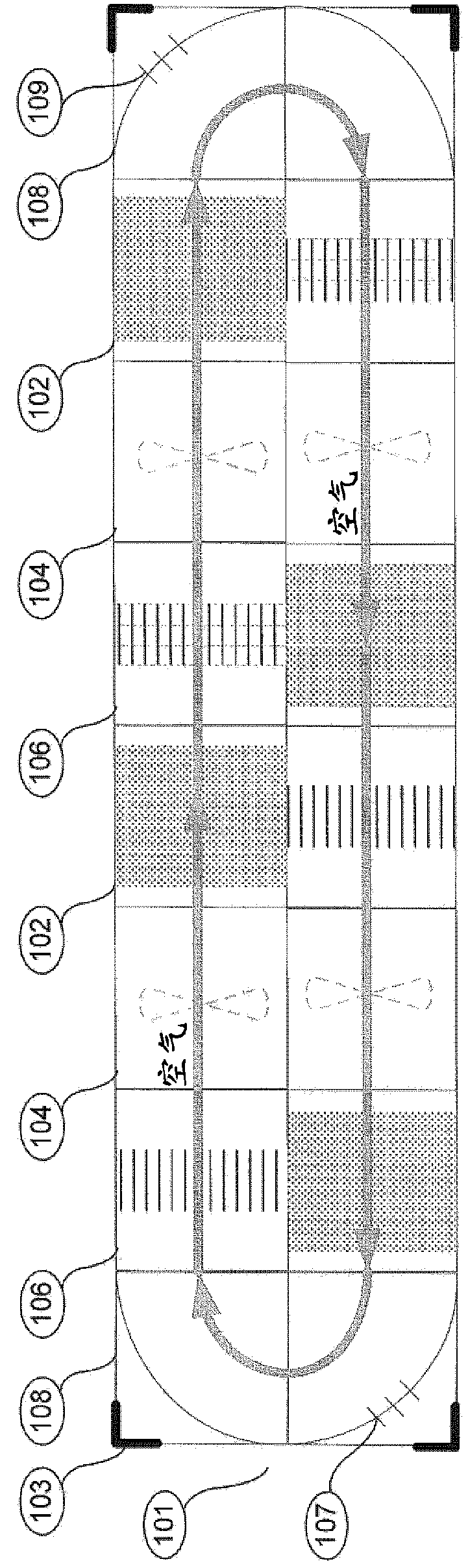

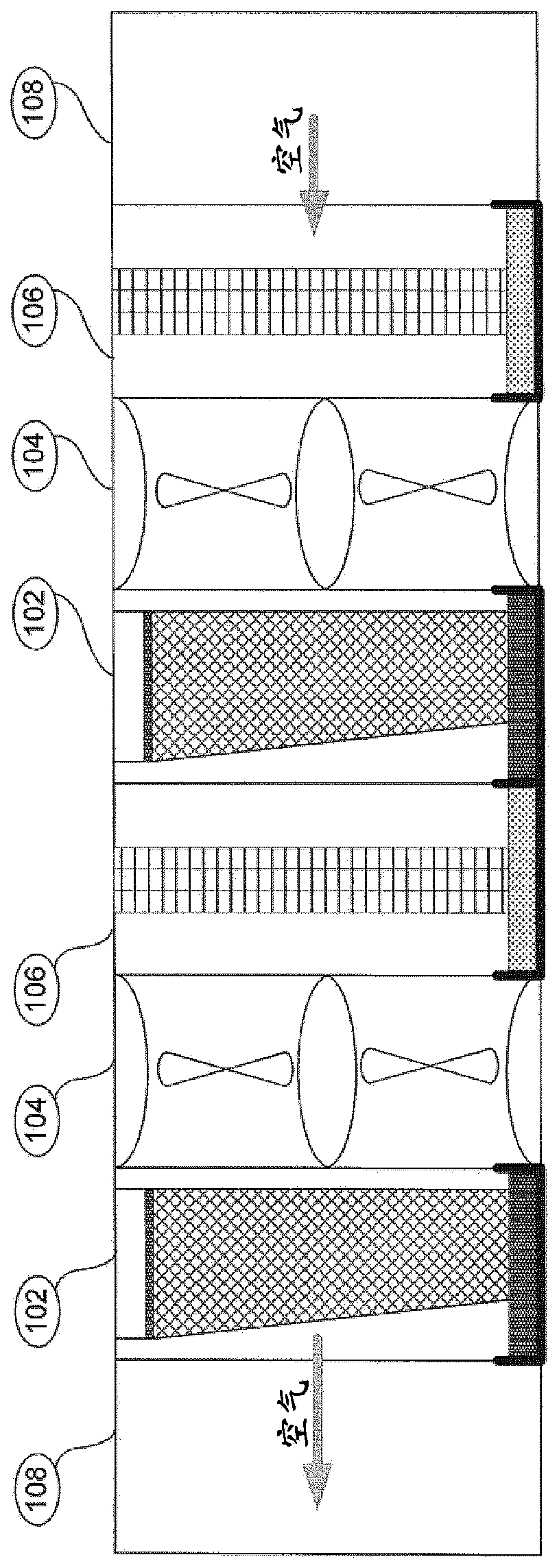

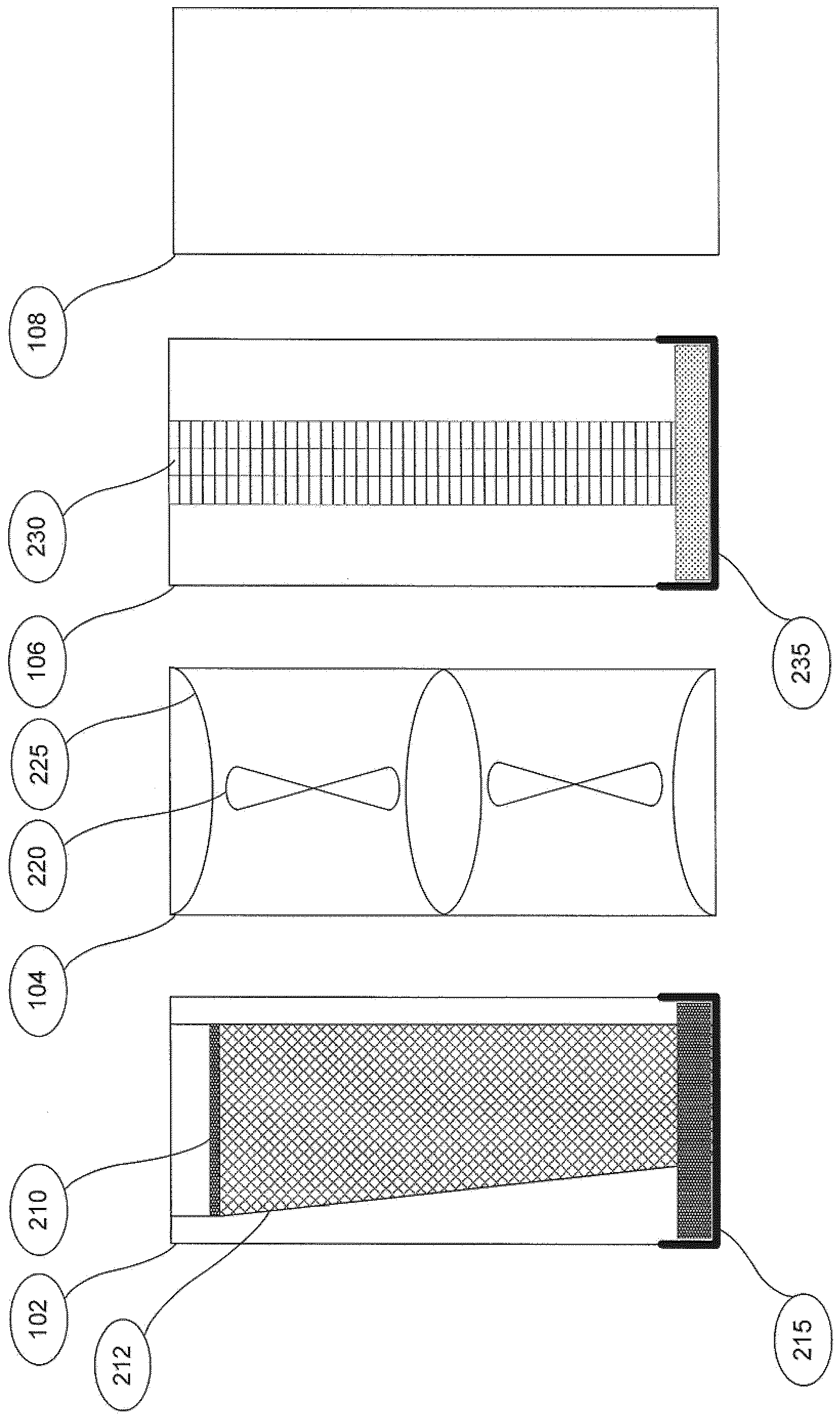

[0038] Embodiments described herein relate to a modular humidification-dehumidification (HDH) unit and an HDH system comprising two or more modular HDH units thermally coupled to each other. The modular HDH device includes a plurality of internal modules coupled to each other. The modular HDH units and HDH systems disclosed herein are generally used to desalinate brine, however, the modular HDH units and HDH systems can be used to concentrate any solution.

[0039] In one embodiment, the plurality of internal modules includes a humidification module and a dehumidification module. The humidification module comprises a humi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com