R-T-B-Ga-BASED MAGNET MATERIAL ALLOY AND METHOD FOR PRODUCING SAME

A r-t-b-ga, alloy technology, applied in the direction of magnetic materials, magnetic objects, metal processing equipment, etc., to achieve the effect of improving saturation magnetization, improving and stabilizing coercivity, and increasing residual magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

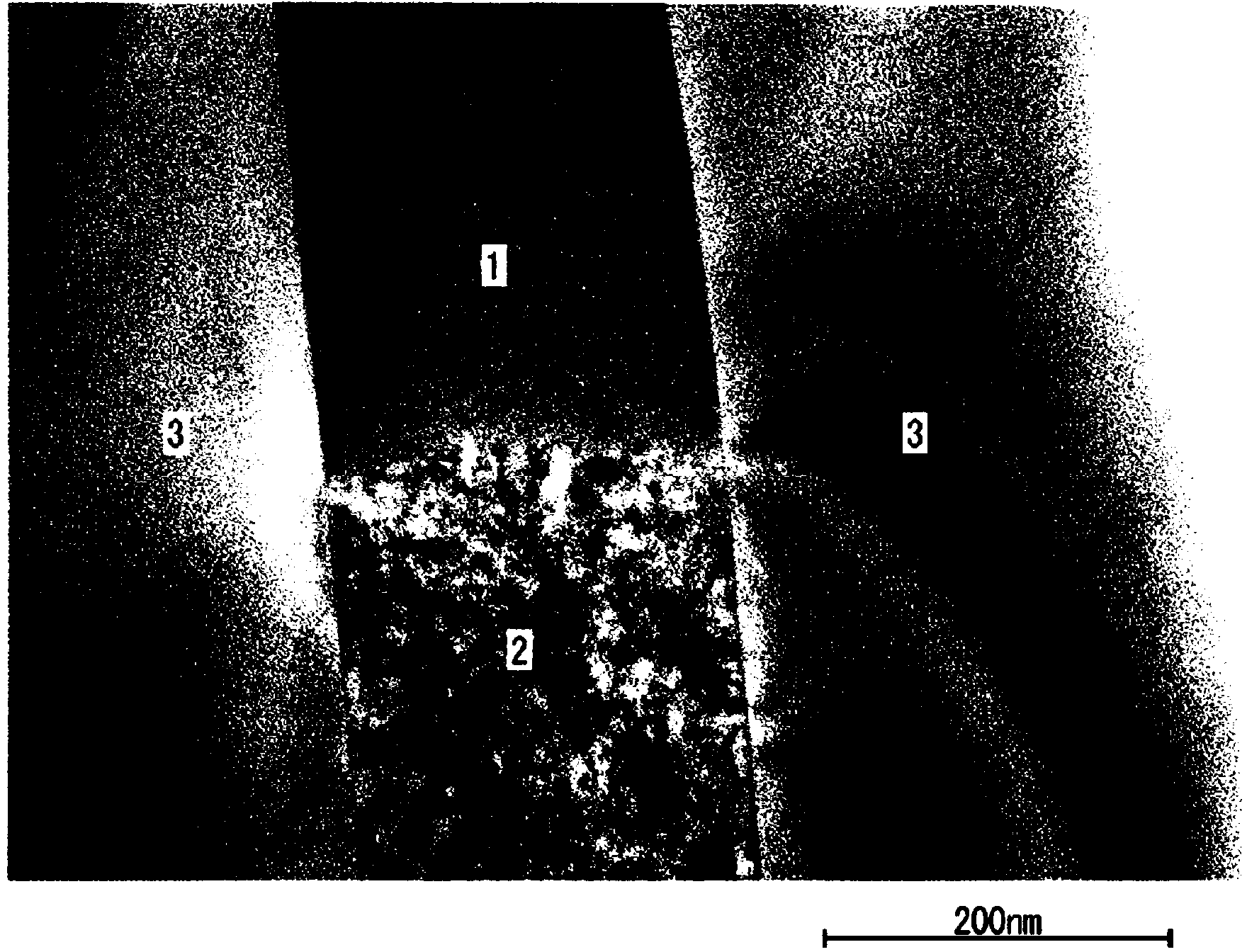

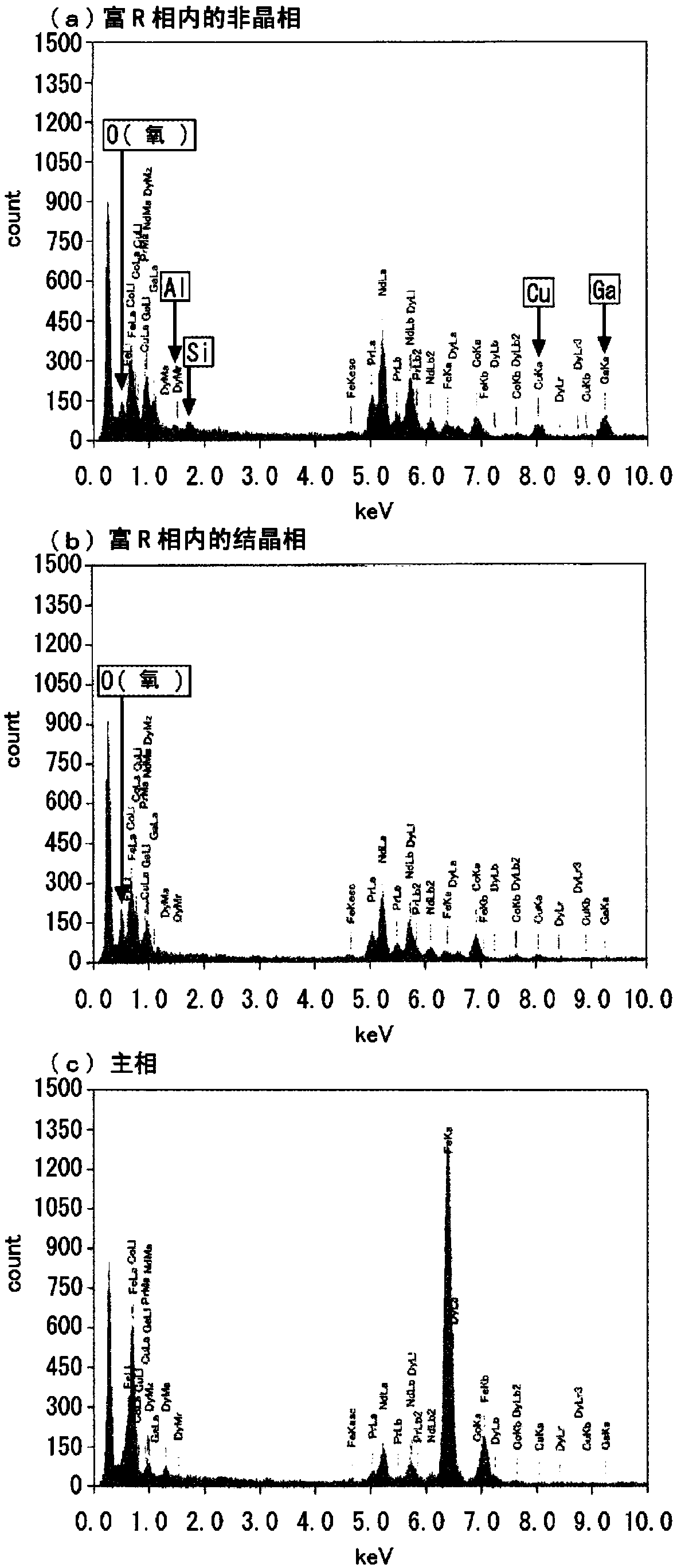

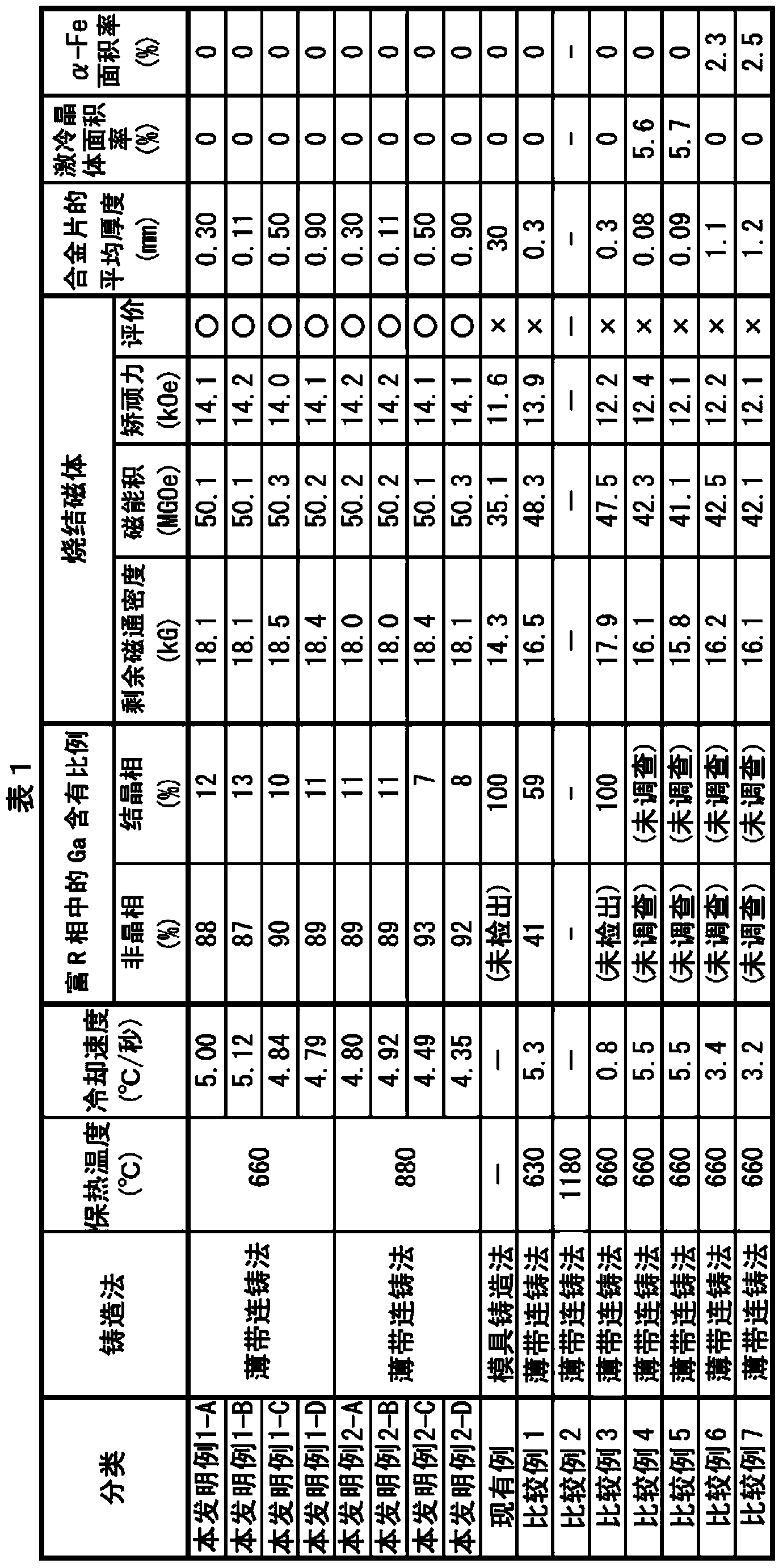

[0099] In order to verify the effect of the raw material alloy for a magnet of the present invention and its manufacturing method, an R-T-B-Ga-based alloy was produced to investigate the crystal structure. In addition, a sintered magnet was obtained using the produced R-T-B-Ga-based alloy as a raw material, and the magnetic properties of the sintered magnet were confirmed.

[0100] 1. Test method

[0101] [Raw material alloys for magnets]

[0102] In this test, R-T-B-Ga-based alloy flakes were prepared through the procedures of Examples 1 and 2 of the present invention, Conventional Examples, and Comparative Examples 1 to 3 described below. Regardless of any step, the composition of the R-T-B-Ga alloy sheet contains Nd: 24.0%, Pr: 5.0%, Dy: 2.0%, B: 1.0%, Ga: 0.10%, and the rest is Fe and Impurities. The melting point of the R-T-B-Ga alloy flake with this composition is about 650°C.

[0103]In Example 1-A of the present invention, in a chamber with an Ar atmosphere of 300 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com