Functional carbon wrapping Fe3O4 multihole nanocomposite and preparing method thereof and application of functional carbon wrapping Fe3O4 multihole nanocomposite serving as drug carrier

A nanocomposite material, carbon coating technology, applied in the field of nanomaterials, can solve the problems of low porosity, application limitation, low specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

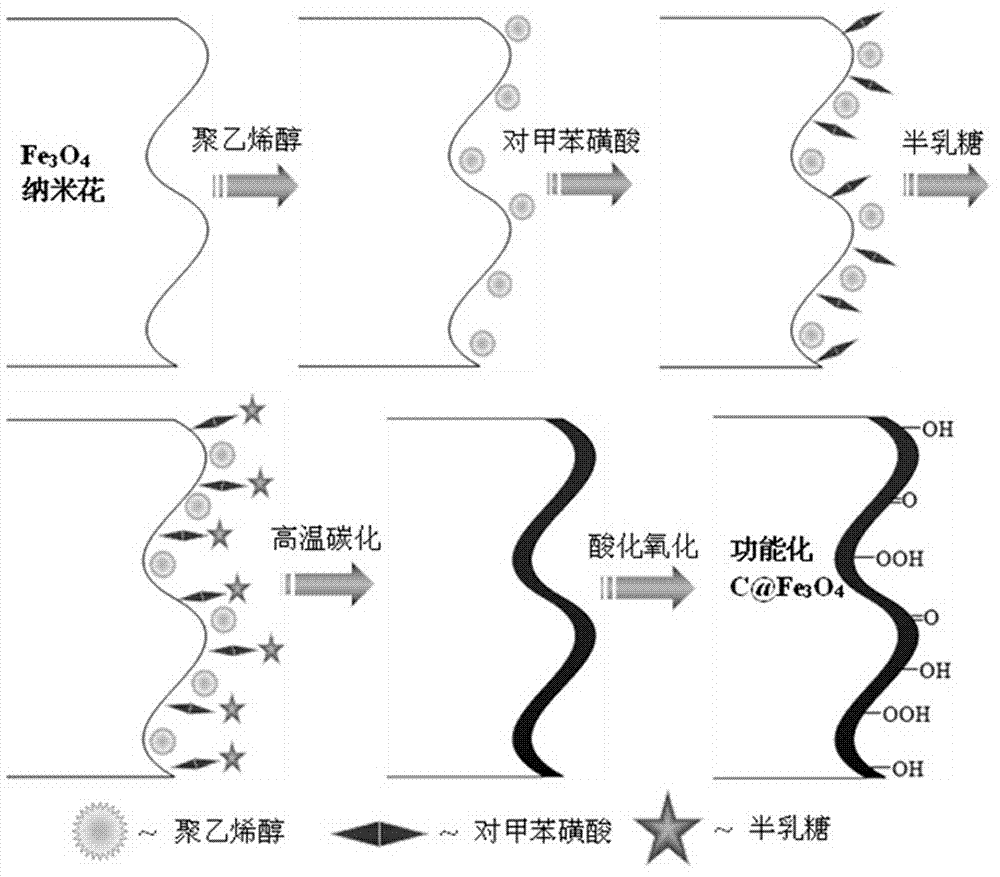

[0062](1) Add 2g of reduced iron powder and 30mL of 2mol / L nitric acid solution into the reactor, stir to fully dissolve; then apply a 0.4T magnetic field at the bottom of the reactor, and slowly inject ammonia gas into the reactor Mixed gas with air (the volume ratio of ammonia gas to air is 8:1); when the pH value reaches 10, stop feeding the gas, gradually raise the temperature to 70°C, seal the reactor, and keep it for 3 hours; the obtained product is washed and vacuum-dried , get Fe 3 o 4 Nano flower-like nanoparticles;

[0063] (2) Weigh 0.1gFe 3 o 4 Nano flower-like particles, dispersed in 10mL aqueous solution containing 0.4g polyvinyl alcohol and sonicated for 20 minutes; respectively added 4.5g p-toluenesulfonic acid and 0.035g galactose, stirred vigorously and mixed for 30 minutes; the mixture was transferred to an autoclave In the process, react at 100°C for 1 hour, then gradually raise the temperature to 185°C, and carbonize for 8 hours; after cooling, extract...

Embodiment 2

[0066] (1) Add 2g of reduced iron powder and 30mL of 2mol / L nitric acid solution into the reactor, stir to fully dissolve; then apply a 0.6T magnetic field at the bottom of the reactor, and slowly inject ammonia gas and Mixed gas of air (the volume ratio of ammonia gas to air is 8:1); when the pH value reaches 11, stop feeding the gas, gradually raise the temperature to 70°C, seal the reactor, and keep it for 4 hours; the obtained product is washed, vacuum-dried, Get Fe 3 o 4 Nano flower-like nanoparticles;

[0067] (2) Weigh 0.1gFe 3 o 4 Nano flower-like particles, dispersed in 10mL aqueous solution containing 0.4g polyvinyl alcohol and sonicated for 20 minutes; respectively added 4.5g p-toluenesulfonic acid and 0.04g galactose, vigorously stirred and mixed for 30 minutes; the mixture was transferred to an autoclave In the process, react at 100°C for 1 hour, then gradually raise the temperature to 185°C, and carbonize for 8 hours; after cooling, extract the product with a...

Embodiment 3

[0070] (1) Add 2g of reduced iron powder and 30mL of 2mol / L nitric acid solution into the reactor, stir to fully dissolve; then apply a 0.6T magnetic field at the bottom of the reactor, and slowly inject ammonia gas and Mixed gas of air (the volume ratio of ammonia gas to air is 8:1); when the pH value reaches 12, stop feeding the gas, gradually raise the temperature to 75°C, seal the reactor, and keep it for 5 hours; the obtained product is washed, vacuum-dried, Get Fe 3 o 4 Nano flower-like nanoparticles;

[0071] (2) Weigh 0.1gFe 3 o 4 Nano flower-like particles, dispersed in 10mL aqueous solution containing 0.45g polyvinyl alcohol and sonicated for 20 minutes; respectively added 3.5g p-toluenesulfonic acid and 0.035g galactose, stirred vigorously for 30 minutes; the mixture was transferred to a high-pressure reactor In the process, react at 100°C for 1 hour, then gradually raise the temperature to 185°C, and carbonize for 8 hours; after cooling, extract the product wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com