A low-cost high-saturation magnetization iron-based soft magnetic alloy and its preparation method

A magnetization, soft magnetic alloy technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of low saturation magnetization, high saturation magnetization, limited use range, etc., to achieve high saturation magnetization, good saturation Magnetization intensity, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

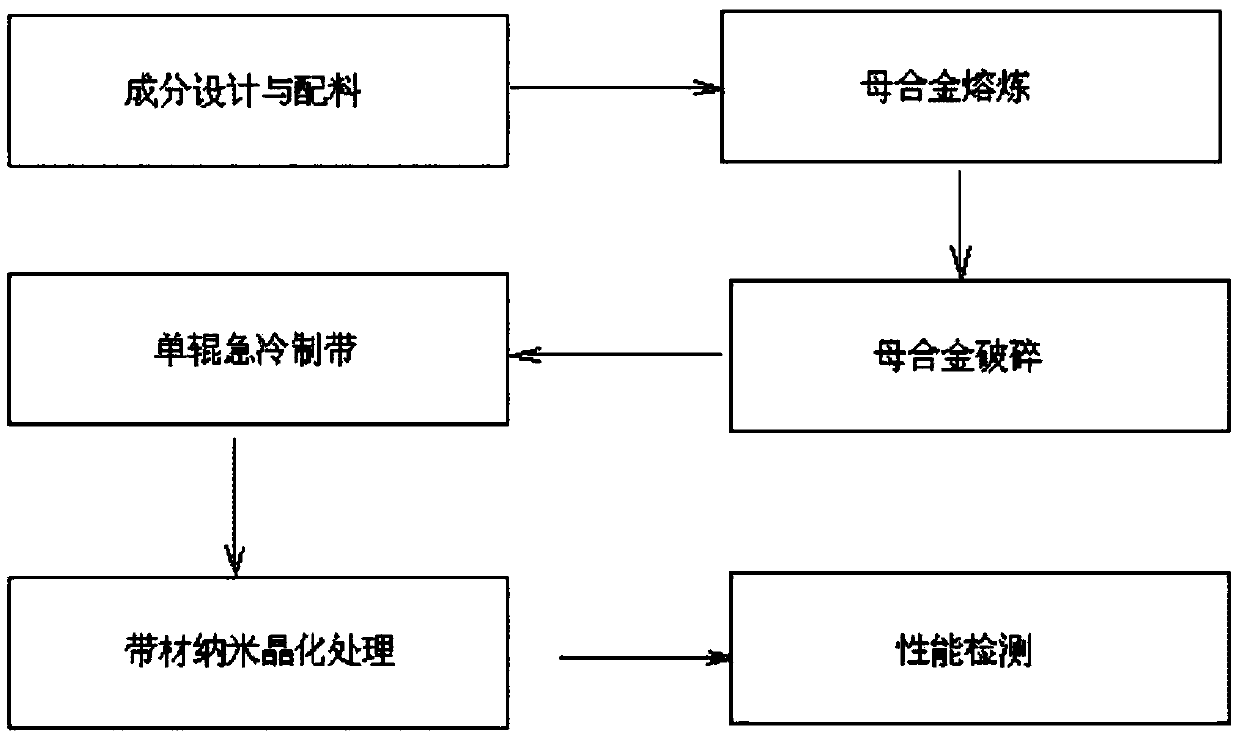

[0065] Weigh metal raw materials iron, boron iron, copper, carbon iron and niobium according to a certain proportion, and put them into a vacuum melting furnace to prepare alloy ingots. This process needs to be smelted repeatedly (at least 3 times) to make the alloy components smelt evenly; smelting The temperature is 1800~2000℃; the time of each smelting is about 15.

[0066] The alloy ingot was crushed and put into acetone solution, cleaned in ultrasonic waves, and dried in the air for later use.

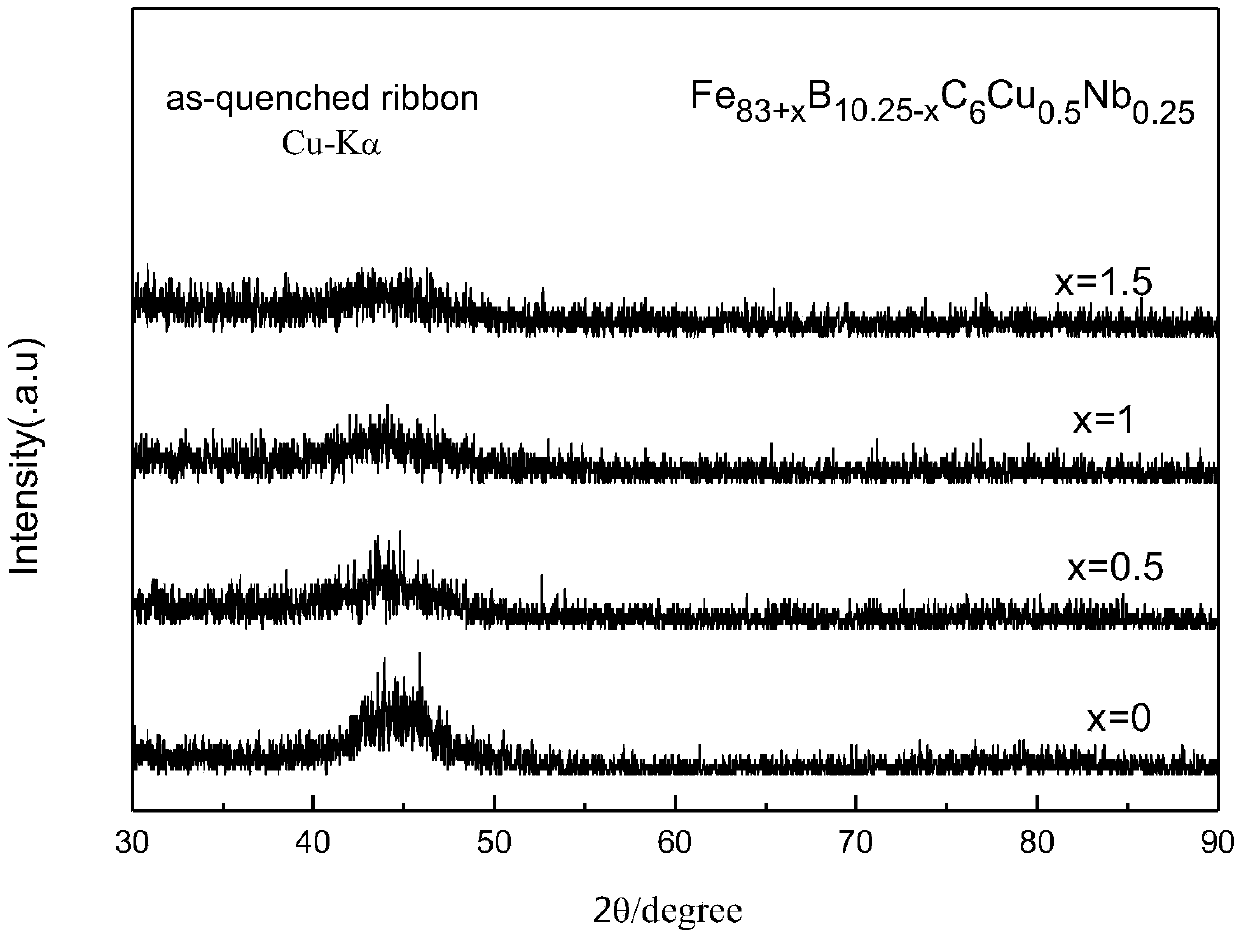

[0067] Put the crushed alloy ingot into the quartz tube of the quenching strip-making equipment, and use the single-roll quenching strip method at a speed of 50m / s to prepare a thin alloy strip with a width of 2 mm and a thickness of about 25 microns.

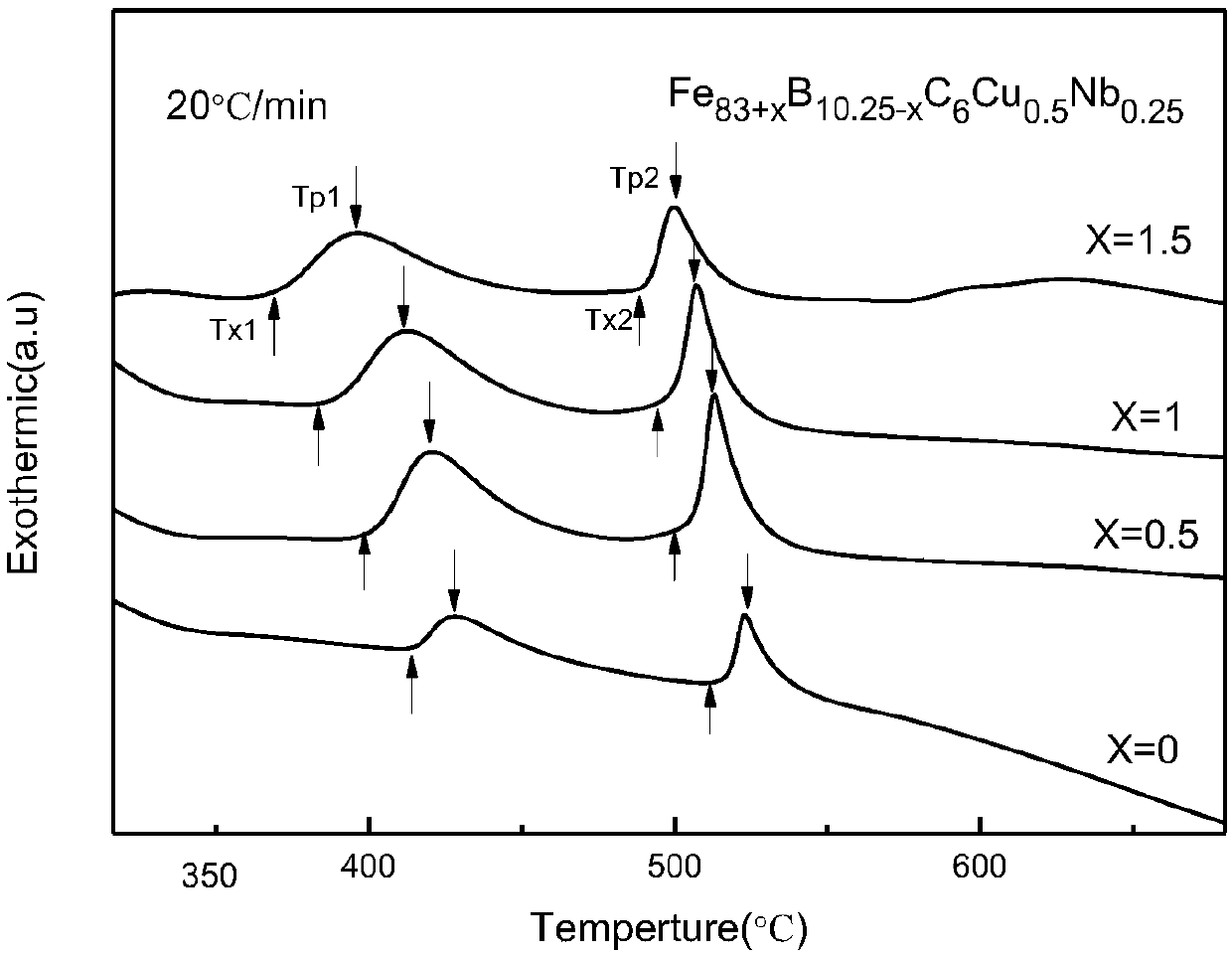

[0068] Put the prepared amorphous alloy thin strip into a heat treatment furnace, under the protection of nitrogen gas environment, raise the temperature to 440°C at a heating rate of 20°C / min, keep it warm for 10 minutes, and then...

Embodiment 2

[0074] Weigh metal raw materials iron, boron iron, copper, carbon iron and niobium according to a certain proportion, and put them into a vacuum melting furnace to prepare alloy ingots. This process needs to be smelted repeatedly (at least 3 times) to make the alloy components smelt evenly; smelting The temperature is 1800~2000℃; the time of each melting is about 15s.

[0075] The alloy ingot was crushed and put into acetone solution, cleaned in ultrasonic waves, and dried in the air for later use.

[0076] Put the crushed alloy ingot into the quartz tube of the quenching strip-making equipment, and use the single-roll quenching strip method at a speed of 50m / s to prepare a thin alloy strip with a width of 2 mm and a thickness of about 25 microns.

[0077] Put the prepared amorphous alloy strip into a heat treatment furnace, under the protection of nitrogen gas environment, raise the temperature to 420°C at a heating rate of 20°C / min, keep it warm for 10 minutes, and then cool...

Embodiment 3

[0083] Weigh metal raw materials iron, boron iron, copper, carbon iron and niobium according to a certain proportion, and put them into a vacuum melting furnace to prepare alloy ingots. This process needs to be smelted repeatedly (at least 3 times) to make the alloy components smelt evenly; smelting The temperature is 1800~2000℃; the time of each melting is about 15s.

[0084] The alloy ingot was crushed and put into acetone solution, cleaned in ultrasonic waves, and dried in the air for later use.

[0085] Put the crushed alloy ingot into the quartz tube of the quenching strip-making equipment, and use the single-roll quenching strip method at a speed of 50m / s to prepare a thin alloy strip with a width of 2 mm and a thickness of about 25 microns.

[0086]Put the prepared amorphous alloy strip into a heat treatment furnace, under the protection of nitrogen gas environment, raise the temperature to 420°C at a heating rate of 20°C / min, keep it warm for 10 minutes, and then cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com