Vertical logistics based solvent crystallization method

A crystallization method and solvent technology, applied in the field of aseptic logistics, can solve the problem of low sterility assurance level, and achieve the effect of improving the sterility assurance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

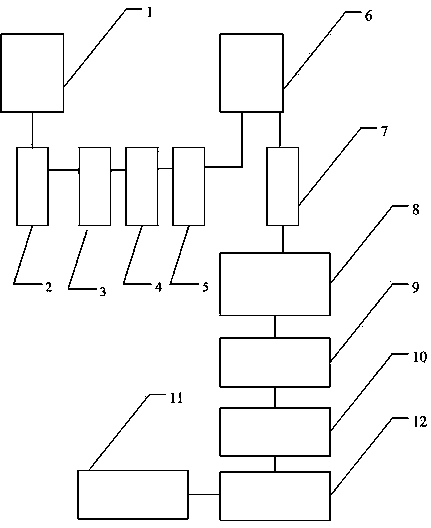

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. figure 1 Schematic diagram of the process flow for the preparation of sterile raw materials by the fully aseptic docking solvent crystallization method for vertical logistics, as shown in figure 1 shown.

[0024] Based on the solvent crystallization method of vertical flow, after the crystal growth step of the solvent crystallization method is completed, the solid-liquid separation of the feed liquid is carried out, and the separated solid is transferred by gravity in a sterile environment. The solid-liquid separation device is specifically a sterile horizontal scraper centrifuge. The solids are transported along a vertical path by gravity. The specific implementation method is as follows: the raw material is dissolved in the dissolving tank 1, and after the activated carbon is decolorized, the activated carbon is removed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com