Continuous gradient supplementation method and device applied to efficient expanding propagation of haematococcus pluvialis

A kind of Haematococcus pluvialis, gradient technology, applied in the biological field, can solve the problems of low cell biomass astaxanthin yield, low cell photosynthetic activity, great influence of seasonal changes, etc., to shorten the culture period, easy and efficient operation, The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take Haematococcus pluvialis FACHB-797 as an example, but it does not constitute a limitation to the present invention, the method can be applied to all concurrently trophic (heterotrophic) Haematococcus pluvialls.

[0034] A continuous gradient feeding method applied to the efficient propagation of Haematococcus pluvialis provenance, the steps are:

[0035] A. Preparation of different gradient feed medium:

[0036] The medium in the tank used in the case is the improved kobayashi’s basal medium, in which the yeast extract is replaced by sodium nitrate, and the proportion of the rest of the components is as follows: 1.2g sodium acetate (CH 3 COONa), 0.405g (L-asparagine (L-asparagine), 0.5g sodium nitrate (NaNO 3 ), 0.2g magnesium chloride hexahydrate (MgCl 2 ·6H 2 O), 0.01g ferrous sulfate heptahydrate (FeSO 4 ·7H 2O), 0.02g calcium chloride dihydrate (CaCl 2 2H 2 O) and 1000mL deionized water; the prepared whole culture medium was sterilized at a high temperatu...

Embodiment 2

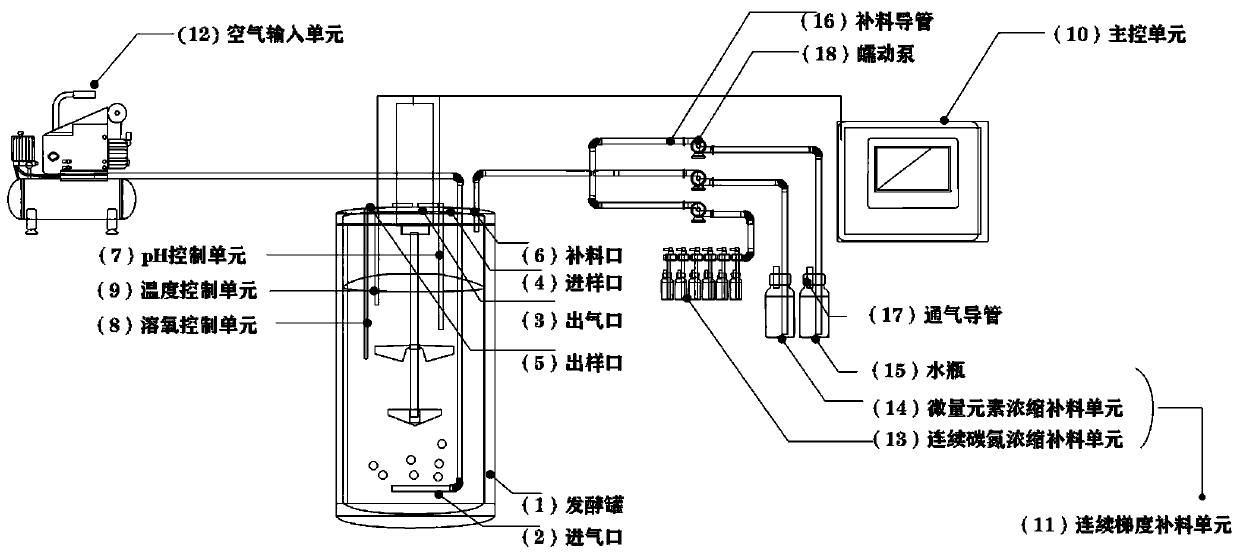

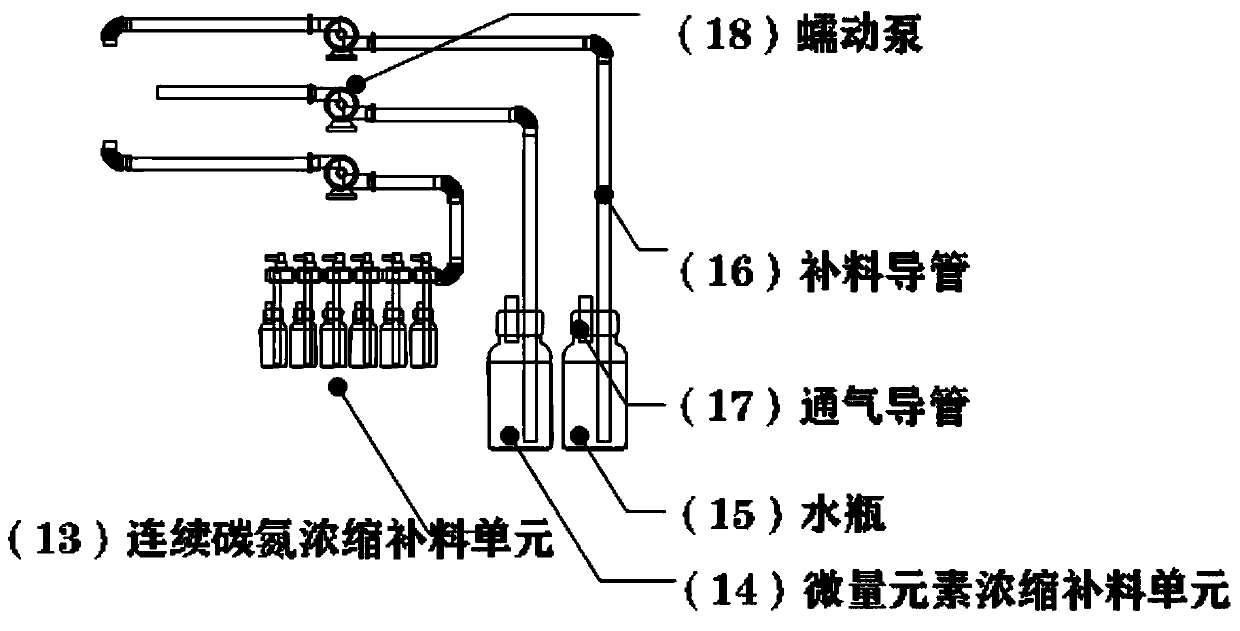

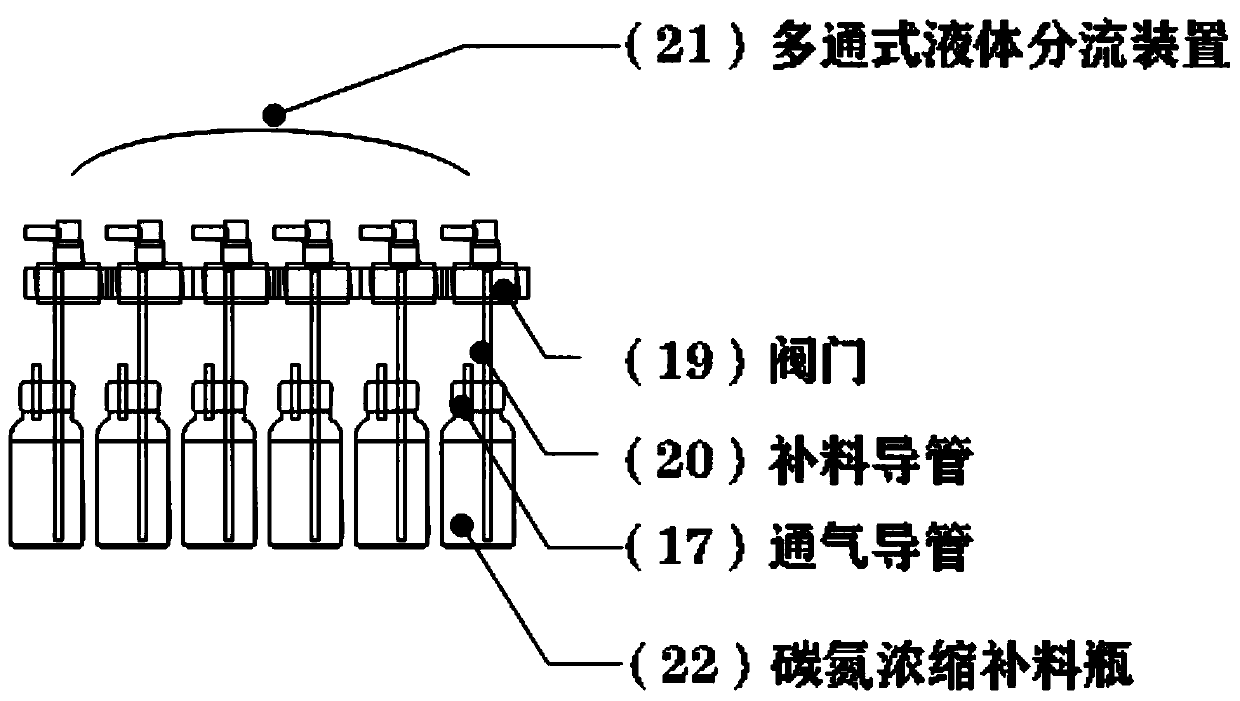

[0048] according to figure 1 , figure 2 , image 3 It can be seen that a continuous gradient feeding method is applied to the device for the efficient propagation of Haematococcus pluvialis provenance. Feed port 6, pH control unit 7, dissolved oxygen control unit 8, temperature control unit 9, main control unit 10, continuous gradient feeding unit 11, air input unit 12, continuous carbon and nitrogen concentration feeding unit 13, trace element concentration feeding Material unit 14, water bottle 15, feeding conduit 16, ventilation conduit 17, peristaltic pump 18, valve 19, feeding conduit 20, multi-pass liquid diversion device 21, carbon and nitrogen concentrated feeding bottle 22, characterized in that: The tank 1 is respectively connected with the main control unit 10, the continuous gradient feed unit 11, and the air input unit 12 to form the main part of the culture tank of Haematococcus pluvialis. The main control unit 10 is connected with the pH control unit 7 and th...

Embodiment 3

[0051] A continuous gradient feeding method applied to the efficient propagation of Haematococcus pluvialis provenance, the process is:

[0052] Photosynthetic induction of astaxanthin was carried out on the immobile cells obtained by the continuous gradient feeding method in indoor conditions, and the cells from the above sources were diluted 10 times with sterilized tap water, and the light conditions were 100 μmol photons m -2 ·s -1 , the temperature was controlled at 24 or 25 or 26 ° C, cultured for 8 or 9 or 10 days, and the final astaxanthin yield was 15.45 mg L -1 d -1 , with an average biomass yield of 0.50 g L -1 d -1 .

[0053] The effect is shown in Table 1. Table 1 is a comparison between this device and the reported "two-step method" to cultivate Haematococcus pluvialis to produce astaxanthin. The results show that the continuous gradient feeding method and device are applied to the efficient propagation of Haematococcus pluvialls. A large number of iminetin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com