Preparation method and application of durian skin based biomass charcoal material

A biomass charcoal, durian peel technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as pollution, waste of resources and the environment, and achieve convenient separation operation, high adsorption efficiency, and fast adsorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

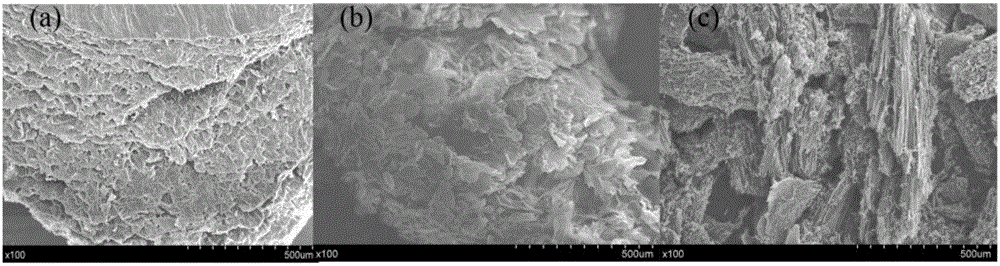

[0025] The present invention prepares durian peel-based biochar material through the following method, and characterizes it.

[0026] The yellow-green hard thorny skin of fresh durian was removed, washed three times with tap water and distilled water respectively, cut into pieces, frozen at -20°C in the refrigerator for 24 hours, and freeze-dried in a vacuum freeze-drying oven at -80°C for 48 hours to obtain sample 1.

[0027] Remove the yellow-green hard thorny skin from the fresh durian skin, wash with tap water and distilled water three times respectively, cut into pieces and put them in a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C in a blast drying oven for 10 hours, and place the preliminary carbonized durian skin at 70 Soak in a hot water bath for 2 days. Then, the soaked durian skin was placed in the refrigerator to freeze at -20°C for 24 hours, and then freeze-dried in a vacuum freeze-drying oven at -80°C for 48 hours to obtain sample 2....

Embodiment 2

[0032] Adsorption rate test experiment: Take a piece of sample 3 (durian peel-based biochar material) prepared by the method in Example 1 and weigh it, then immerse it in oil or organic liquid and let it stand for adsorption for 30s~5min, take it out, and weigh it immediately , to calculate the adsorption capacity of the adsorbent.

[0033] The calculation formula of the adsorbent capacity provided by the present invention is:

[0034] Adsorption rate (%) = (m 2 -m 1 ) / m 1 *100 (1)

[0035] Among them, m 1 and m 2 Respectively refer to the mass of the adsorbent before and after the adsorption of oil or organic liquid.

[0036] Use formula (1) to calculate the effect of durian skin-based biochar on pump oil, castor oil, N,N-dimethylformamide (DMF), ethanol, acetone, p-xylene (PX), n-heptane, toluene, The adsorption rate of methanol, formic acid, N-methylpyrrolidone (NMP) and other oils or organic substances, the results are as follows Figure 7 shown. The durian skin-b...

Embodiment 3

[0038] Cyclic performance test experiment: take a piece of sample 3 (durian peel-based biochar material) prepared by the method in Example 1 and weigh it, then immerse it in acetone and let it stand for adsorption for 30s-5min, take it out, weigh it immediately, and calculate the adsorbent The adsorption rate of the first cycle. Then, the adsorbent after adsorption was placed in a watch glass, placed in a blast drying oven, and dried to constant weight (20 min) at 100°C to complete the first adsorption-desorption-regeneration cycle experiment.

[0039] According to the steps described above, carry out 5 adsorption-desorption-regeneration cycle experiments, such as Figure 8 As shown, the structure shows that the durian skin-based biochar material has good regeneration cycle performance, and the adsorption rate of the fifth adsorption-desorption-regeneration cycle of acetone solvent is 95% of the adsorption rate of the first cycle. In addition, regeneration of the adsorbent ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com