A method for fermenting and producing Bacillus subtilis with chondroitin sulfate production industrial wastewater as raw material

A technology of Bacillus subtilis and chondroitin sulfate, which is applied in the field of microbial fermentation, and achieves the effects of low equipment requirements, reduced burden, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

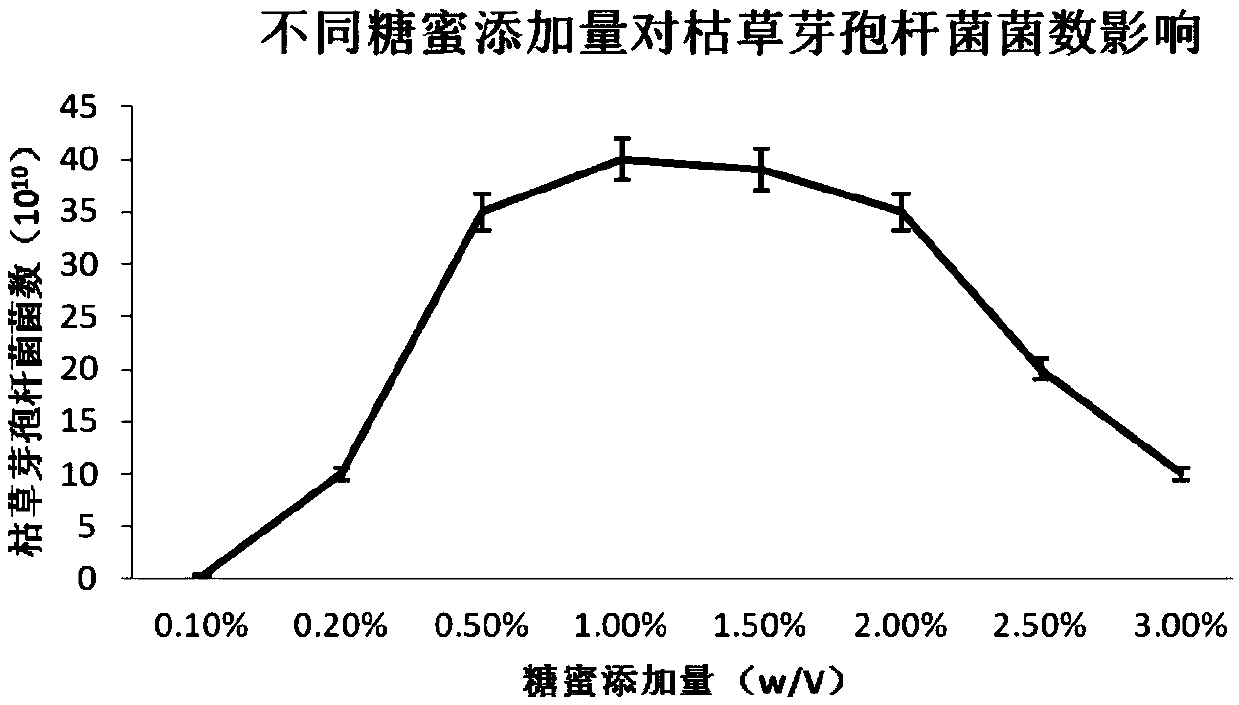

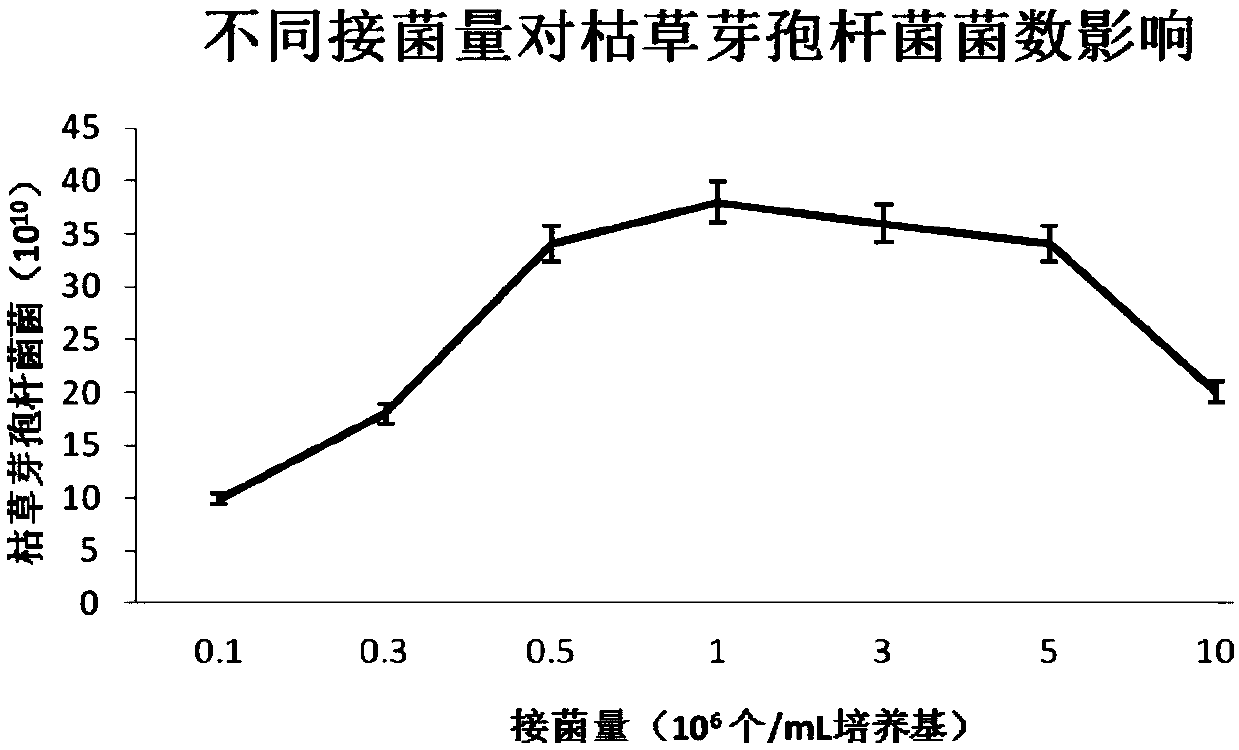

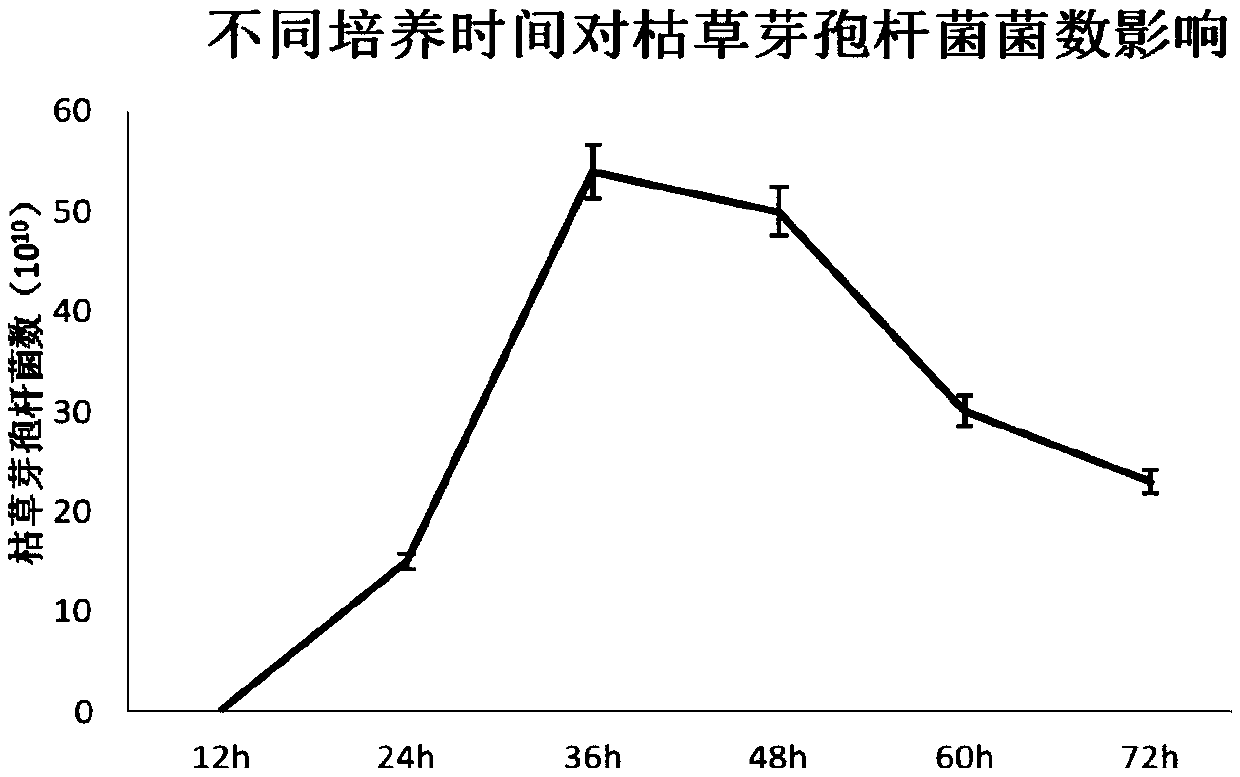

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Use animal cartilage to extract 10L of industrial wastewater produced by the process of extracting chondroitin sulfate, add 50g of molasses according to the mass ratio of 0.5%, mix and dissolve, use NaOH or HCl to fine-tune the pH=6.5-7.0, and extinguish at high temperature at 121°C Bacteria 20min, cooling, according to the final concentration of 5 × 10 5 Inject appropriate amount of Bacillus subtilis into each / mL medium, and the specific parameters of the 10L liquid fermentation tank are as follows: temperature control 37°C, tank pressure 0.05mpa, 0-6h speed 150rpm, ventilation volume 1:0.5; 6-24h speed 250rpm, ventilation volume 1:1.2; after 24 hours, the rotation speed is 150rpm, and the ventilation rate is 1:0.5. After 36 hours of fermentation, the number of Bacillus subtilis detected by the method of GB / T 26428-2010 "Detection of Bacillus subtilis in microbial preparations for feed" > 6.0×10 10 individual / mL. The fermented liquid is concentrated 10 to 2...

Embodiment 2

[0026] Example 2: Use animal cartilage to extract 10L of industrial wastewater produced by the process of extracting chondroitin sulfate, add 120g of molasses according to the mass ratio of 2.5%, mix and dissolve, use NaOH or HCl to fine-tune the pH=6.5-7.0, and extinguish at high temperature at 121°C Bacteria for 20min, cooled, according to the final concentration of 1 × 10 6 Inject appropriate amount of Bacillus subtilis into each / mL medium, and the specific parameters of the 10L liquid fermentation tank are as follows: temperature control 37°C, tank pressure 0.05mpa, 0-6h speed 150rpm, ventilation volume 1:0.5; 6-24h speed 250rpm, ventilation volume 1:1.2; after 24 hours, the rotation speed is 150rpm, and the ventilation rate is 1:0.5. After 48 hours of fermentation, the number of Bacillus subtilis detected by the method of GB / T 26428-2010 "Detection of Bacillus subtilis in microbial preparations for feed" > 5.0×10 11individual / mL. The fermented liquid is concentrated 10 t...

Embodiment 3

[0027] Example 3: 10L of industrial wastewater produced by the process of extracting chondroitin sulfate from animal cartilage was added to 200g of molasses according to a mass ratio of 5.0%, mixed and dissolved, then finely adjusted to pH=6.5-7.0 with NaOH or HCl, and extinguished under high temperature at 121°C Bacteria 20min, cooling, according to the final concentration of 5 × 10 6 Inject appropriate amount of Bacillus subtilis into each / mL medium, and the specific parameters of the 10L liquid fermentation tank are as follows: temperature control 37°C, tank pressure 0.05mpa, 0-6h speed 150rpm, ventilation volume 1:0.5; 6-24h speed 250rpm, ventilation volume 1:1.2; after 24 hours, the rotation speed is 150rpm, and the ventilation rate is 1:0.5. After 42 hours of fermentation, the number of Bacillus subtilis detected by the method of GB / T 26428-2010 "Detection of Bacillus subtilis in microbial preparations for feed" > 3.0×10 11 individual / mL. The fermented liquid is concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com