Preparation method for titanic iron ore floatation collecting agent

A technology of ilmenite ore and collector, which is applied in flotation, solid separation and other directions, can solve the problems of large amount of collector, complicated chemical system and high chemical cost, and achieves simple flotation chemical system and low temperature flotation. Choose the effect with good effect and low dosage of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

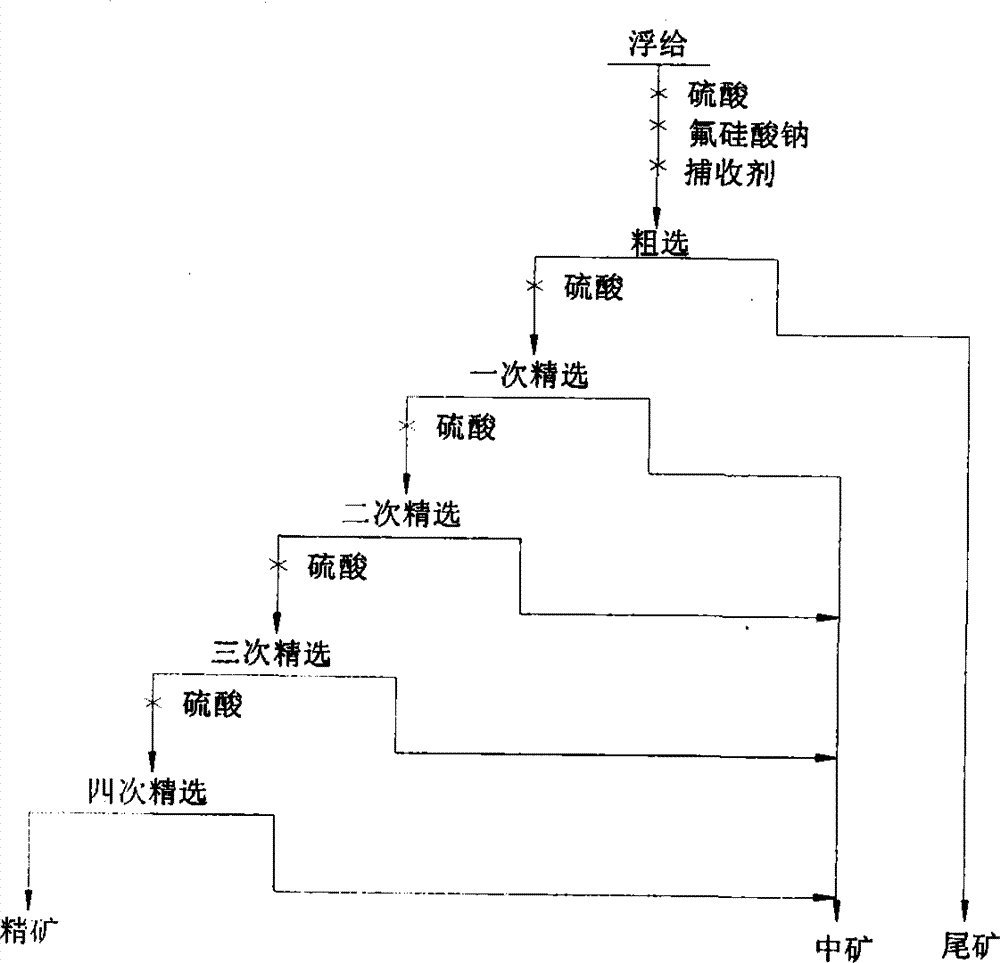

Method used

Image

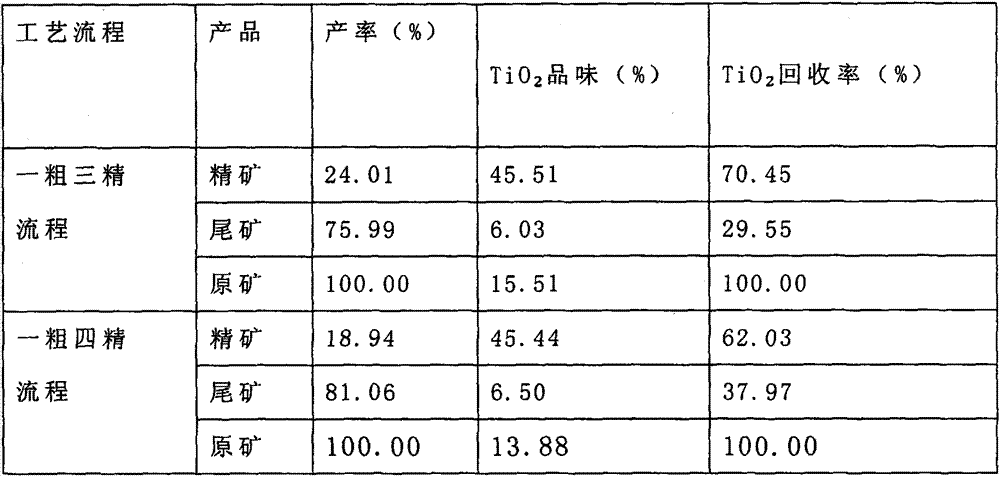

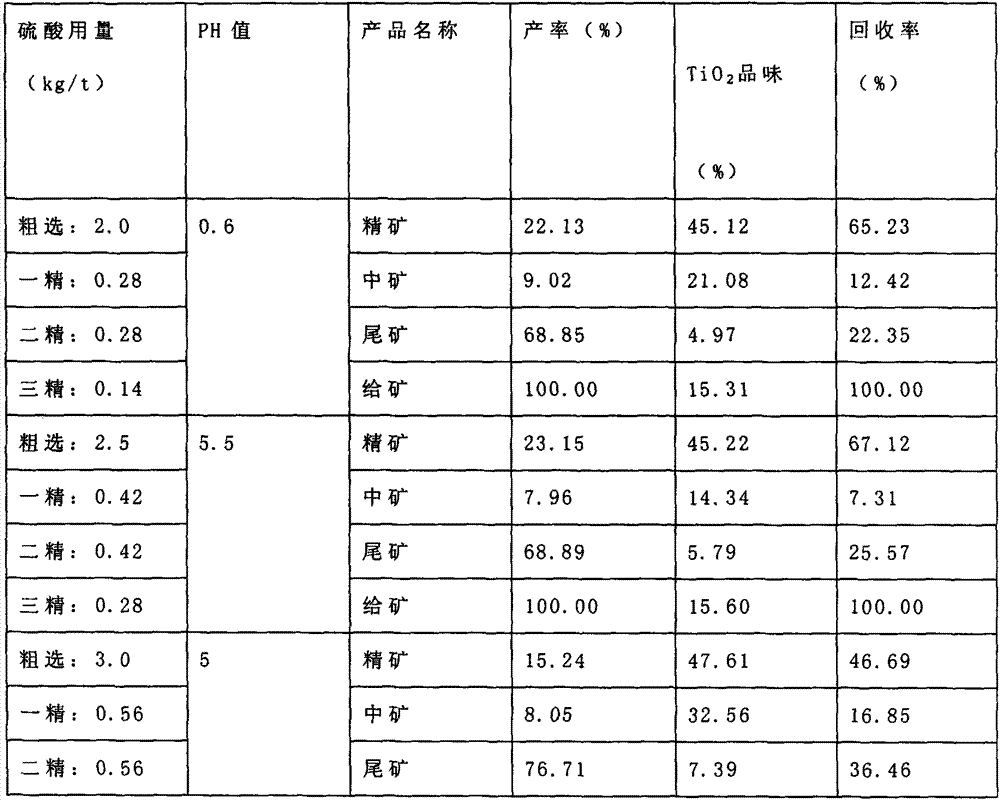

Examples

Embodiment 1

[0044] A preparation method of ilmenite ore flotation collector, the operation steps are as follows:

[0045] 1), using minus five-line dewaxed oil as raw material oil, using oleum solution as sulfonating agent, carrying out sulfonation reaction between the raw material oil and the sulfonating agent to obtain sulfonated products;

[0046] 2), using NaOH solution to saponify the sulfonated compound once to obtain sulfonate;

[0047] 3), compounding the prepared sulfonate with soybean oleic acid and styrene phosphonic acid to form a mixture;

[0048]4), then use NaOH solution to carry out secondary saponification to the compounded mixture to obtain the anionic collector.

[0049] The main component content of the oleum solution is 20wt%.

[0050] The main component content of the NaOH solution used in the step 2) is 15wt%.

[0051] The main component content of the NaOH solution used in the step 4) is 20wt%.

[0052] Sulfonate, soybean oil acid and styrene phosphonic acid ar...

Embodiment 2

[0059] A preparation method of ilmenite ore flotation collector, the operation steps are as follows:

[0060] 1), using minus five-line dewaxed oil as raw material oil, using oleum solution as sulfonating agent, carrying out sulfonation reaction between the raw material oil and the sulfonating agent to obtain sulfonated products;

[0061] 2), using NaOH solution to saponify the sulfonated compound once to obtain sulfonate;

[0062] 3), compounding the prepared sulfonate with soybean oleic acid and styrene phosphonic acid to form a mixture;

[0063] 4), then use NaOH solution to carry out secondary saponification to the compounded mixture to obtain the anionic collector.

[0064] The main component content of the oleum solution is 20wt%.

[0065] The main component content of the NaOH solution used in the step 2) is 15wt%.

[0066] The main component content of the NaOH solution used in the step 4) is 20wt%.

[0067] Sulfonate, soybean oil acid and styrene phosphonic acid a...

Embodiment 3

[0074] A preparation method of ilmenite ore flotation collector, the operation steps are as follows:

[0075] 1), using minus five-line dewaxed oil as raw material oil, using oleum solution as sulfonating agent, carrying out sulfonation reaction between the raw material oil and the sulfonating agent to obtain sulfonated products;

[0076] 2), using NaOH solution to saponify the sulfonated compound once to obtain sulfonate;

[0077] 3), compounding the prepared sulfonate with soybean oleic acid and styrene phosphonic acid to form a mixture;

[0078] 4), then use NaOH solution to carry out secondary saponification to the compounded mixture to obtain the anionic collector.

[0079] The main component content of the oleum solution is 20wt%.

[0080] The main component content of the NaOH solution used in the step 2) is 15wt%.

[0081] The main component content of the NaOH solution used in the step 4) is 20wt%.

[0082] Sulfonate, soybean oil acid and styrene phosphonic acid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com